Sand screening device for constructional engineering

A sand screening technology for construction engineering, which is applied in the field of sand screening devices for construction engineering, can solve problems such as insufficient screening, affecting sand screening efficiency, and difficulty in cleaning impurities, so as to avoid dislocation, ensure screening effect, and ensure reliability The effect of passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

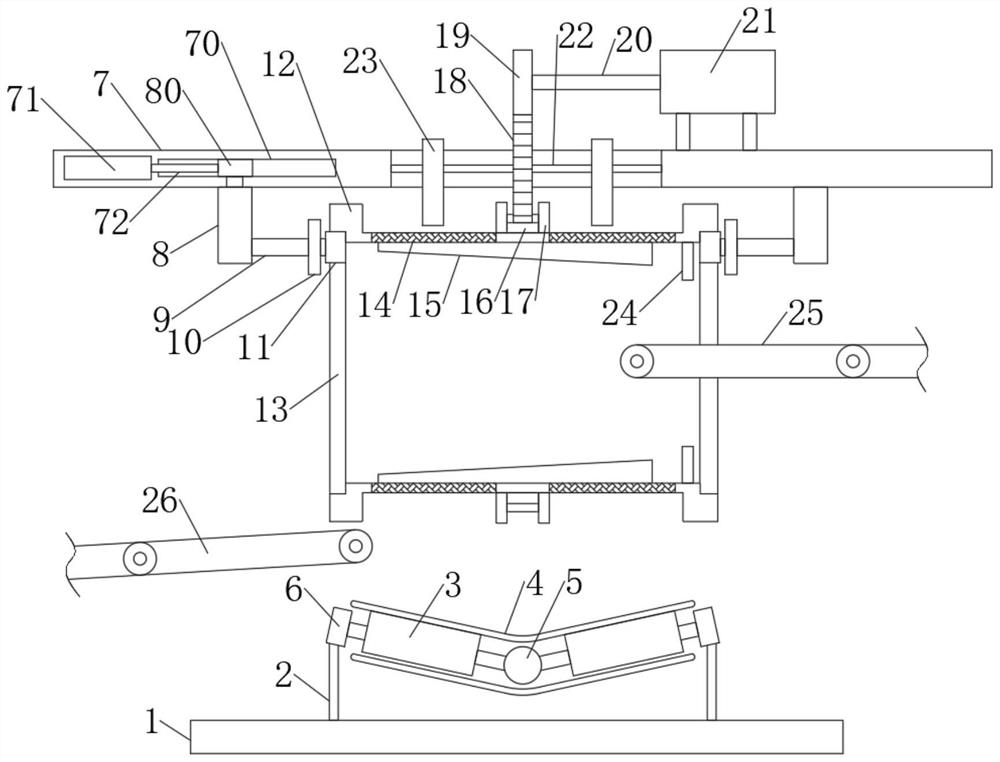

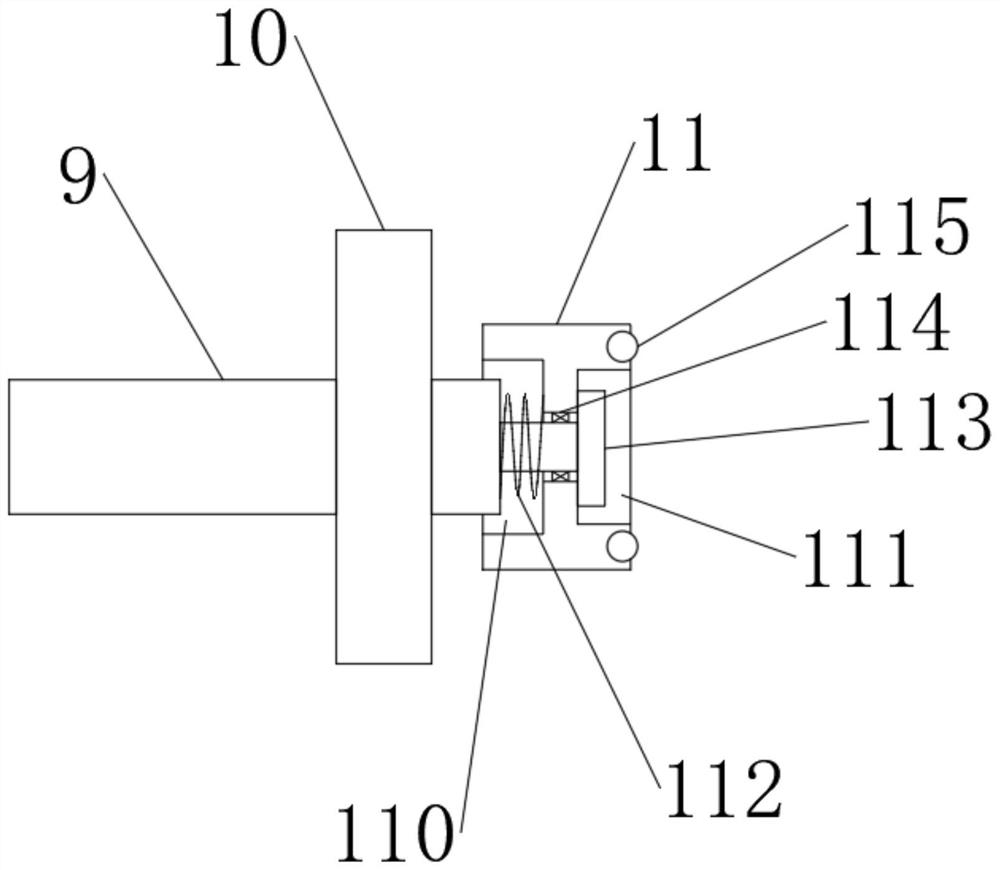

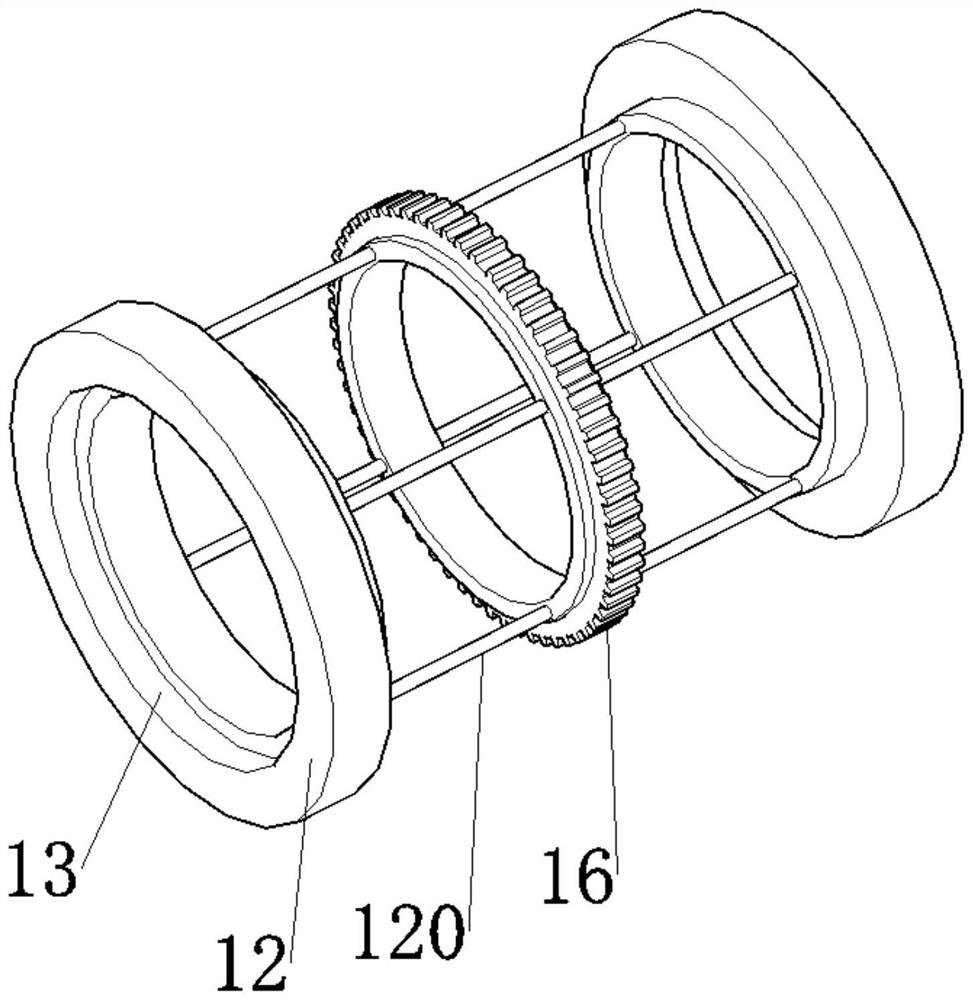

[0029] Such as Figure 1-5 As shown, a sand screening device for construction engineering includes a base 1, a support column 2 is arranged on the base 1, and the support column 2 is connected to a mounting seat 6, and a conveyor belt 4 is provided on the mounting seat 6, The top of the base 1 is provided with a top plate 7, the underside of the top plate 7 is provided with a screen cylinder 12, and the edge of the screen cylinder 12 is provided with a matching groove 13, and the screen cylinder 12 is rolled by the roller 11 and the matching groove 13 Installation, the rollers 11 are rotated and installed with the installation column 9, the installation column 9 is connected to the top plate 7 through the connecting block 8, a screen 14 is arranged on the side wall of the sieve cylinder 12, and a screen 14 is arranged between the sieve cylinder 12 There is a connecting rod 120, the screen 14 is arranged between the connecting rod 120 and the screen drum 12, the middle position...

Embodiment 2

[0046] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0047] A sand screening device for construction engineering, including all parts in embodiment 1, also includes:

[0048] Further, the installation shaft 22 is provided with a cam 23 , and the cam 23 is symmetrically installed on both sides of the intermediate gear 18 .

[0049] Specifically, in order to ensure the screening effect of the screen cylinder 12 and avoid a part of sand with high humidity from adhering to the screen 14, which will affect the overall screening efficiency and screening effect, the cam 23 is installed on the installation shaft 22 to install While the shaft 22 is rotating, it regularly beats the screen cloth 14 on the screen cylinder 12, so as to avoid the sand from adhering to the drying screen and ensure the screening effect.

[0050] Further, a roller 3 is rotatably installed on the mounting seat 6, and the roller 3 is arranged obliquely. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com