Master-slave manipulator and nuclear industry operation room

A manipulator, master-slave technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of limited structure and size of small manipulators, unable to meet the requirements of small master-slave manipulators, complex structure, etc., to meet specifications and small installation space , The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

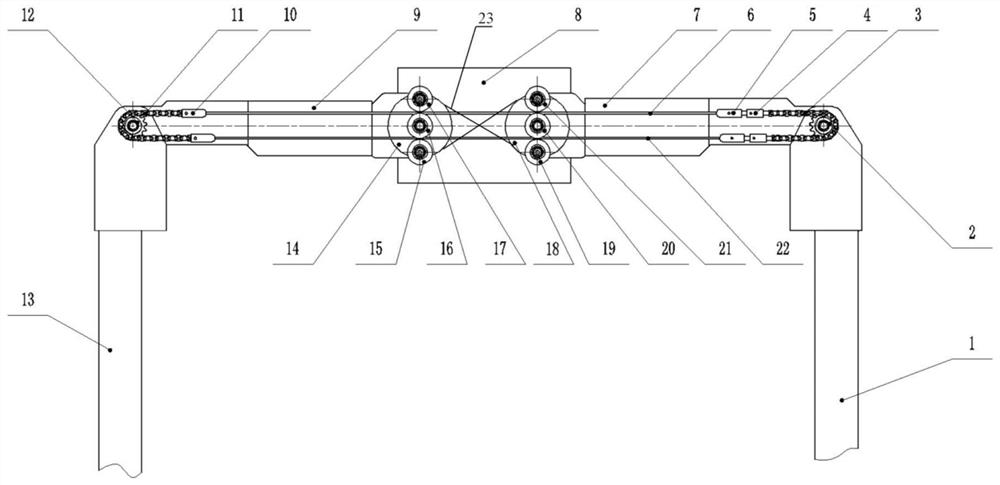

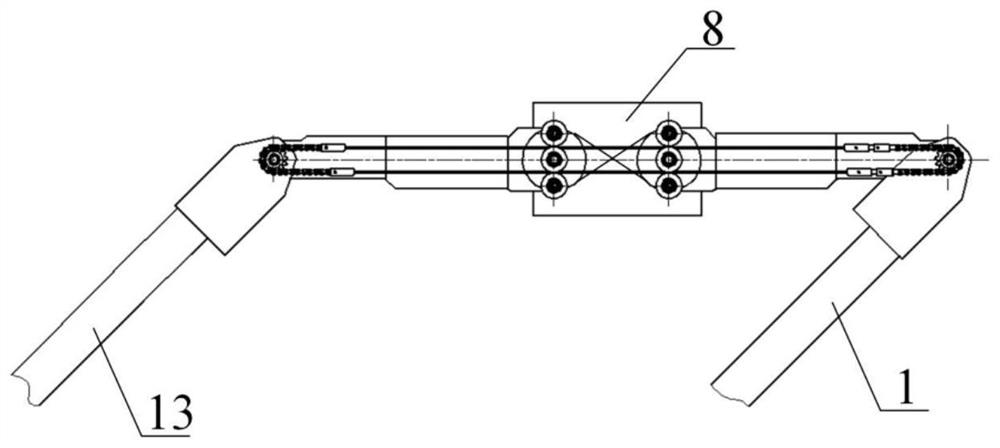

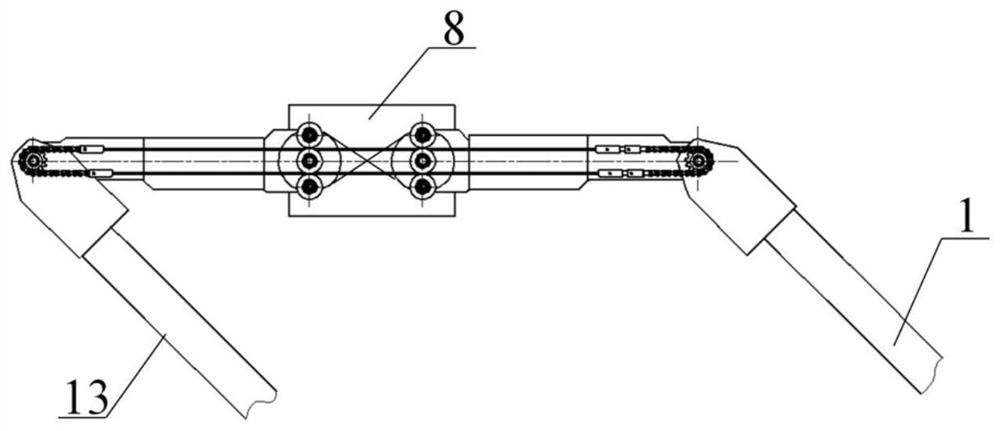

[0056] This embodiment discloses a master-slave manipulator, such as figure 1 As shown, it includes a master hand unit, a slave hands unit, a wall pipe 8 and a force transmission unit, and the master hand unit and the slave hands unit are connected through the wall pipe 8 .

[0057] Wherein, the active hand unit includes an active upper arm 7 and an active forearm 1, and the active upper arm 7 and the active forearm 1 are connected through a first rotation axis.

[0058] The slave hand unit includes a driven upper arm 9 and a driven forearm 13, and the driven upper arm 9 and the driven forearm 13 are connected through a second rotation shaft.

[0059] In this embodiment, the force transmission unit includes a chain transmission mechanism and a moving wheel transmission mechanism.

[0060] Wherein, the chain transmission mechanism passes through the wall pipe 8, and its two ends are respectively arranged on the first rotation axis and the second rotation axis. The chain transm...

Embodiment 2

[0090] This embodiment discloses an operating room in the nuclear industry, which includes a work box and the master-slave manipulator in Embodiment 1. An opening is provided on the wall of the work box, and the wall-through pipe of the master-slave manipulator is arranged in the opening. middle.

[0091] The operating room of the nuclear industry in this embodiment can realize the operation from the outside of the work box to the inside of the work box by using the above-mentioned master-slave manipulator, and can meet the specification requirements of the work box in a narrow space for the master-slave manipulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com