Toughening treatment method of PHBV product

A processing method and product technology, applied in the production of bulk chemicals, etc., can solve problems such as reduction in tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

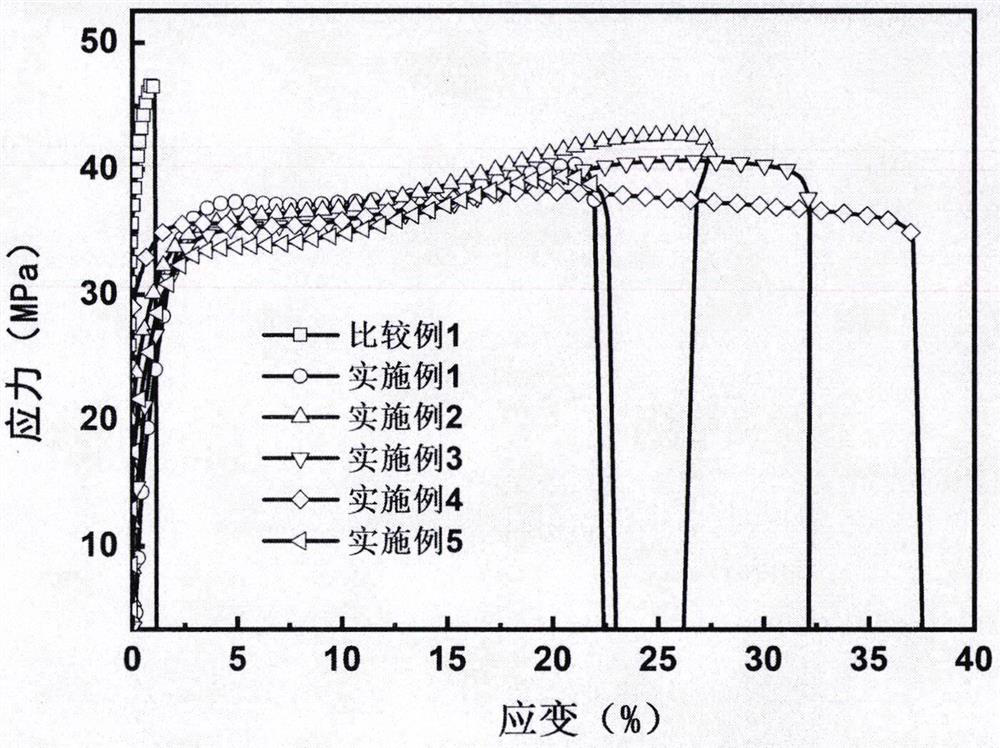

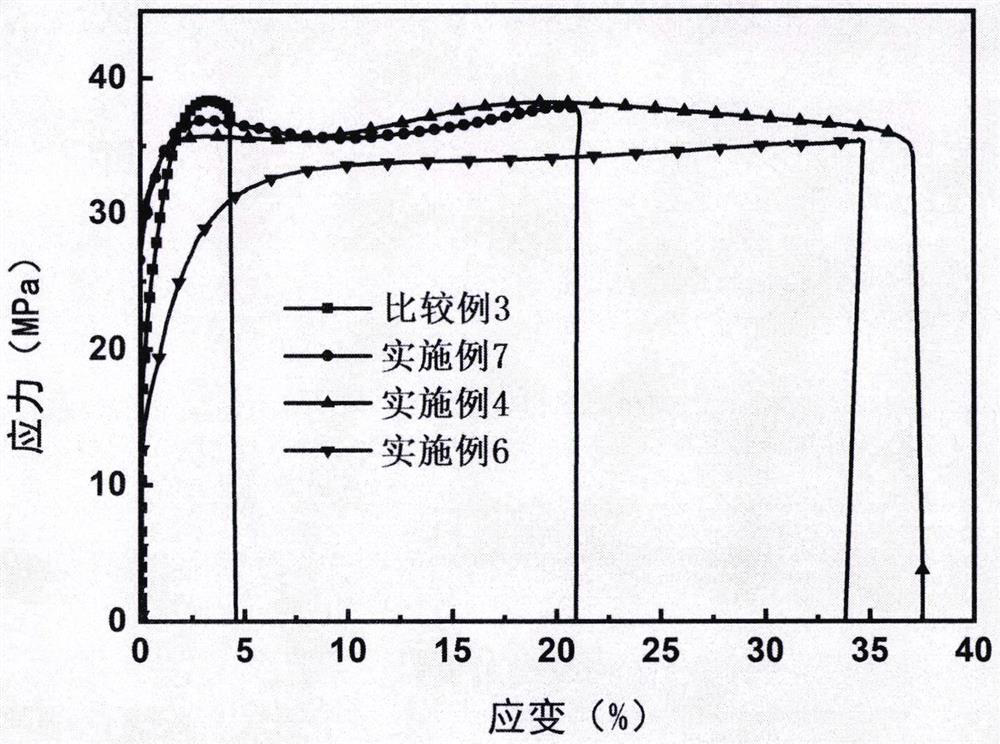

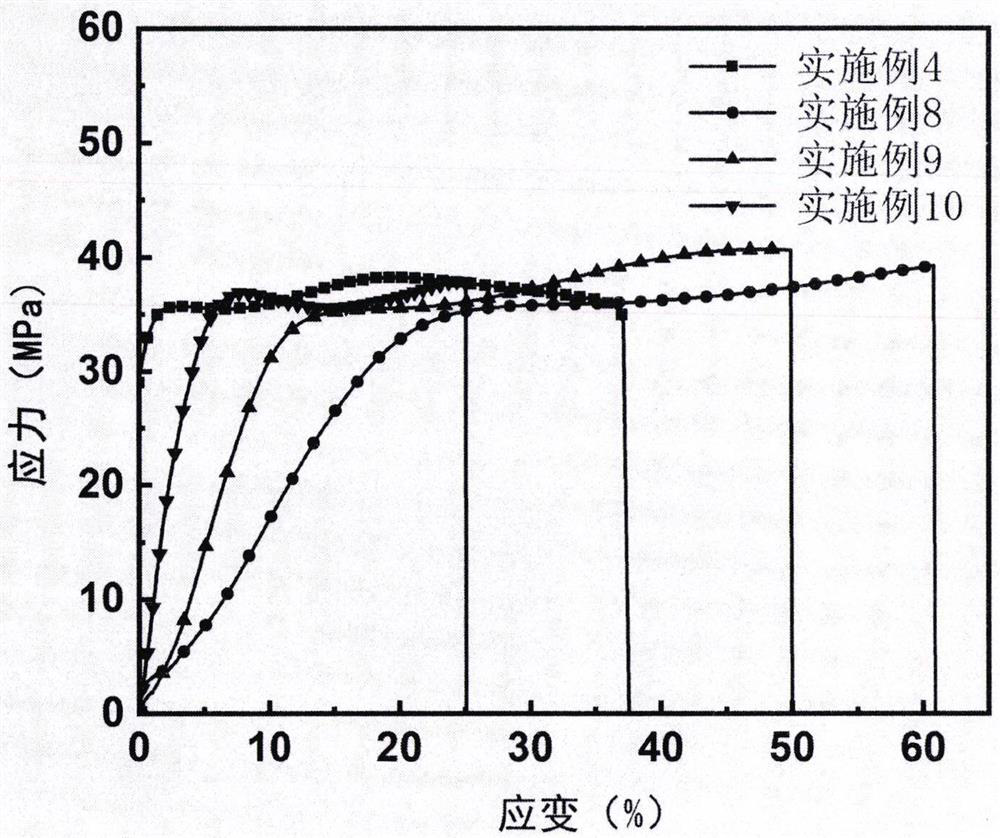

Embodiment 1

[0030] The PHBV sheet was obtained by injection molding, and the thickness of the sheet was 4mm. Among the PHBV raw materials used, the molecular weight was 300,000, and the HV content was 3%. The specific steps are as follows:

[0031] Step 1: Place the PHBV product in a pressure vessel with an infiltration temperature of 175°C, fill it with supercritical carbon dioxide to an infiltration pressure of 10 MPa, and then infiltrate at the infiltration temperature and pressure for 20 minutes; Step 2: Adjust the temperature of the pressure vessel to the saturation temperature for saturation, the saturation temperature is 60°C, and the saturation time is 60 minutes; step 3: depressurize the pressure vessel at a rate of 0.05MPa / s.

Embodiment 2

[0032] Embodiment 2: The saturation temperature is changed from 60° C. to 70° C., and other conditions are the same as in Embodiment 1.

Embodiment 3

[0033] Embodiment 3: The saturation temperature is changed from 60° C. to 80° C., and other conditions are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com