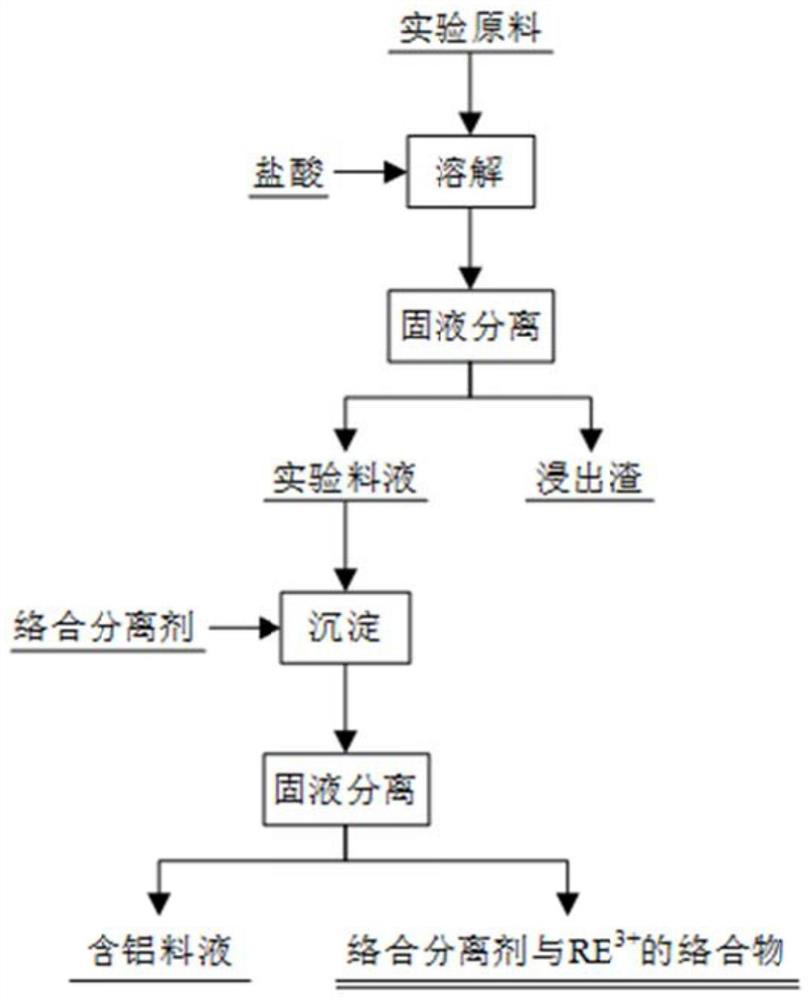

A method for complex separation and removal of aluminum from rare earth feed liquid

A rare earth material liquid, complexation separation technology, applied in the fields of chemistry, hydrometallurgy, and materials, can solve the problems of difficult filtration and separation of flocculent precipitates, the influence of rare earth leaching rate, and the expensive price of oxalic acid, etc., to achieve easy filtration and low equipment requirements , the effect of fast sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

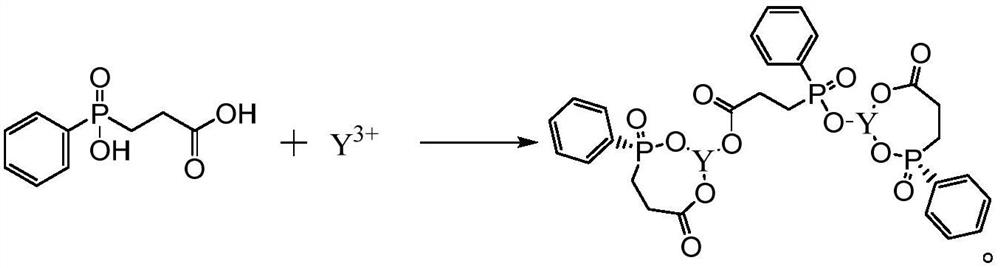

specific Embodiment 1

[0035] (1) Rare earth feed solution: aluminum content 2g / L, rare earth content 5g / L, solution pH=-0.03.

[0036] (2) Pipette 100mL of rare earth feed liquid into a 300mL conical flask, put it into a constant temperature water bath with magnetic stirring, weigh 7.224g of 3-hydroxyphenylphosphoryl propionic acid and slowly add it to the conical flask under constant temperature stirring at 50°C , after stirring for 5 minutes after the feeding is finished, add buffer solution of ammonia and ammonium chloride to slowly adjust the pH=1 of rare earth solution, continue stirring for 10 minutes, and then vacuum filter to obtain precipitate and filtrate. Through the above operations, the precipitation rate of aluminum is 9.52%, and the precipitation rate of rare earth is 90.48%, and the separation of rare earth and aluminum is achieved to a certain extent.

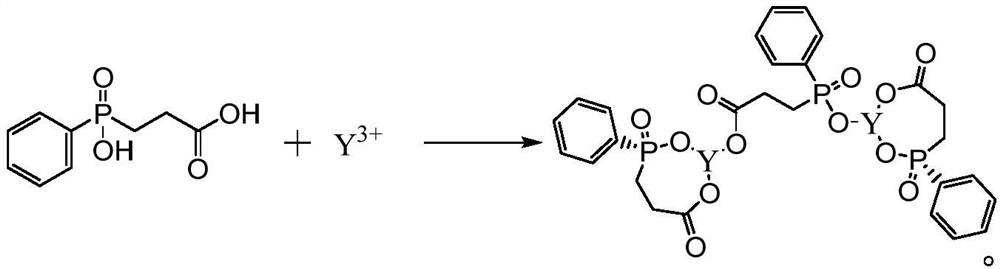

specific Embodiment 2

[0037] (1) Rare earth feed solution: aluminum content 1g / L, rare earth content 5g / L, solution pH=-0.03.

[0038] (2) Pipette 100mL of rare earth feed liquid into a 300mL conical flask, put it into a constant temperature water bath with magnetic stirring, weigh 7.224g of 2-[hydroxy(phenyl)phosphoryl]acetic acid and slowly add it under constant temperature stirring at 30°C In the conical flask, after the feeding is completed, stirring for 10 minutes and dissolving evenly, adding ammonia water and a buffer solution of ammonium chloride to slowly adjust the pH of the rare earth solution to 1, continuing to stir for 10 minutes, and then vacuum filtration to obtain a filtrate. Through the above operations, the precipitation of aluminum in the solution The rate of rare earth is 9.97%, the precipitation rate of rare earth is 90.48%, and the rare earth and aluminum ions are effectively separated.

specific Embodiment 3

[0039] (1) Rare earth feed solution: aluminum content 5g / L, rare earth content 5g / L, solution pH=-0.03.

[0040](2) Pipette 100mL of rare earth feed liquid into a 300mL conical flask, put it into a constant temperature water bath with magnetic stirring, weigh 7.224g of sodium 3-hydroxyphenylphosphoryl propionate and slowly add it to the conical flask under constant temperature stirring at 50°C , after stirring for 15 minutes after the feeding is completed, add the buffer solution of ammonia water and ammonium chloride to slowly adjust the pH=1 of the rare earth solution, and continue to stir for 10 minutes to obtain the filtrate by vacuum filtration. Through the above operations, the precipitation rate of aluminum in the solution is 2.03%. , the precipitation rate of rare earth is 90.48%, which can effectively separate rare earth from aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com