Ultrahigh-speed spinning device for producing HOY

A technology of ultra-high-speed spinning and spinning box, which is applied in the melting of filament raw materials, textile and paper making, filament/thread forming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

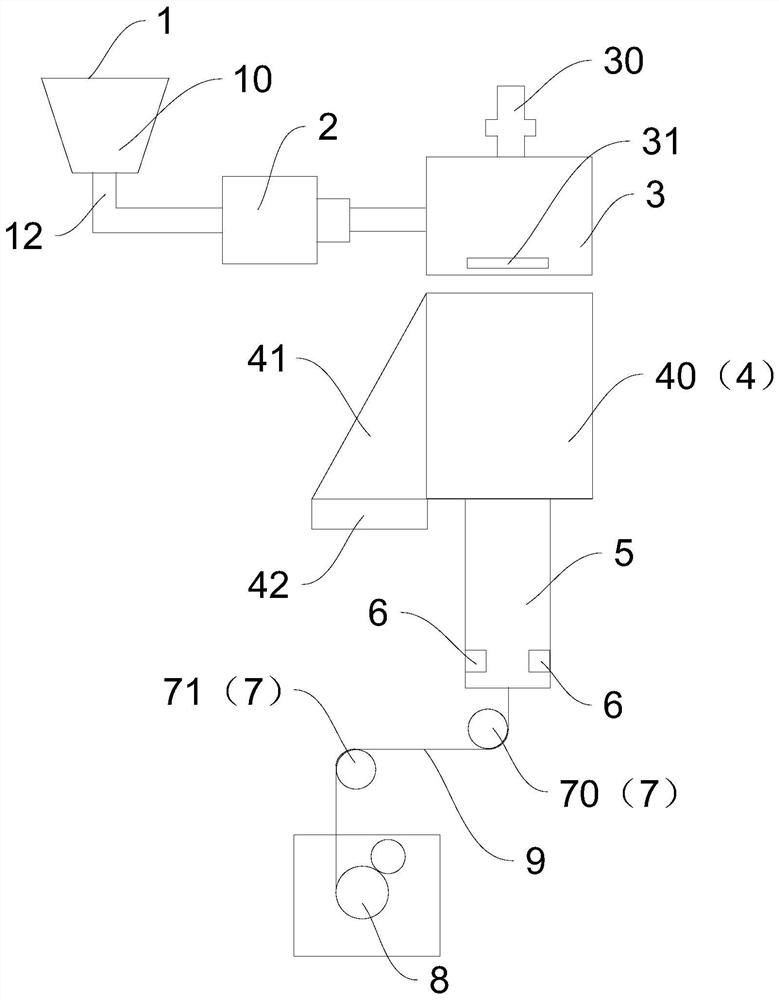

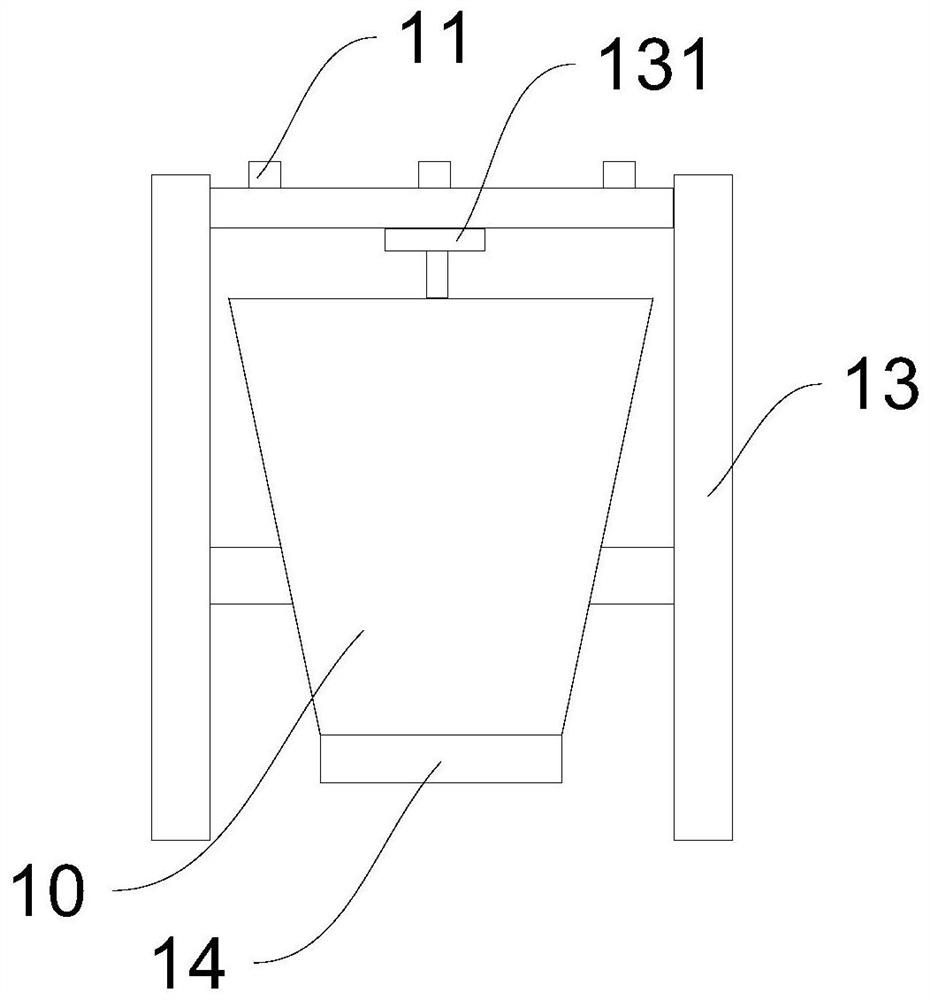

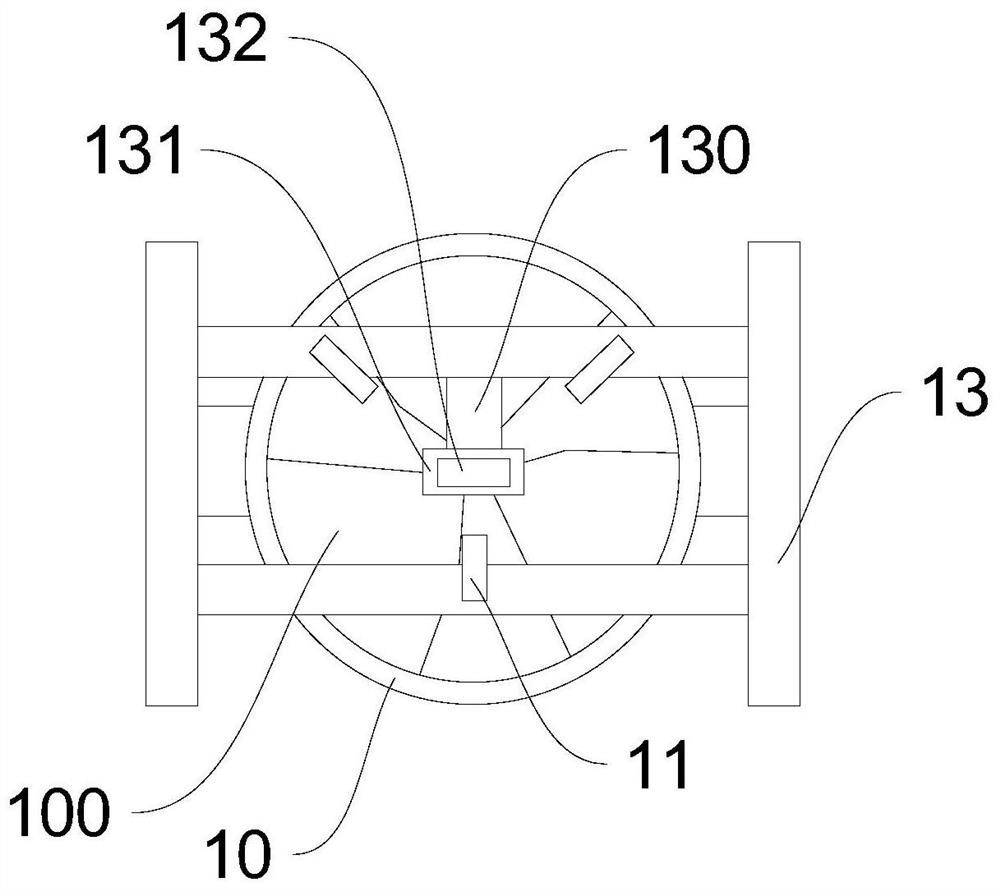

[0026] Embodiment one: if figure 1 As shown, an ultra-high-speed spinning device for producing HOY filaments provided in this embodiment includes a feeding device 1, a screw extruder 2, a spinning box 3, a side blowing device 4, and an oiling device arranged in sequence. Device 6, godet 7 and winder 8, feeding device 1 comprises funnel 10 and is used to add the feed pipe 11 of raw material in funnel 10, and funnel 10 below is provided with discharge pipe 12, and discharge pipe 12 and The feeding port of the screw extruder 2 is connected, and the bottom of the funnel 10 is also rotated with a turntable 14. The spinning raw materials are initially stirred by the turntable 14, and then added to the screw extruder 2. The outlet of the screw extruder 2 Connected with the melt inlet of the spinning box 3, the screw extruder 2 makes the raw material into a molten substance by extruding and melting, and then extrudes the molten substance into the spinning box 3 through the melt inlet....

Embodiment 2

[0030] Embodiment two: if Figure 5 and Figure 6 As shown, a kind of ultra-high-speed spinning device for producing HOY yarn provided by this embodiment, the difference between this embodiment and the above-mentioned embodiment is that the air outlet of the air duct 41 in this embodiment communicates with the bellows 40, and the air duct The air inlet of 41 is connected with a fan 42, and the air duct 41 is provided with an air duct partition plate 410, which is used to divide the air duct 41 into multiple air supply paths.

[0031] Based on the above-mentioned distinguishing technical features, by setting the air duct partition plate 410, the air duct 41 is divided into a plurality of air supply paths, and each air supply path supplies air to different height ranges in the bellows 40, so that it can Adjust the cooling air volume and wind speed accordingly at the height.

[0032] The air duct partition plate 410 in this embodiment includes a first partition plate 411 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com