Moisture-absorbing and quick-drying fabric and preparation method thereof

A technology for moisture absorption and quick drying, and fabrics, applied in the field of textile fabrics, can solve the problems of moisture absorption and quick drying, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

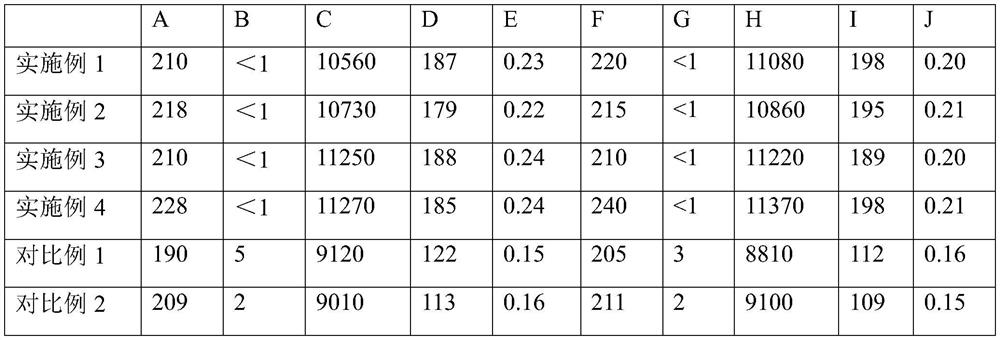

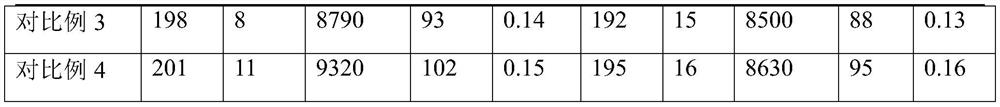

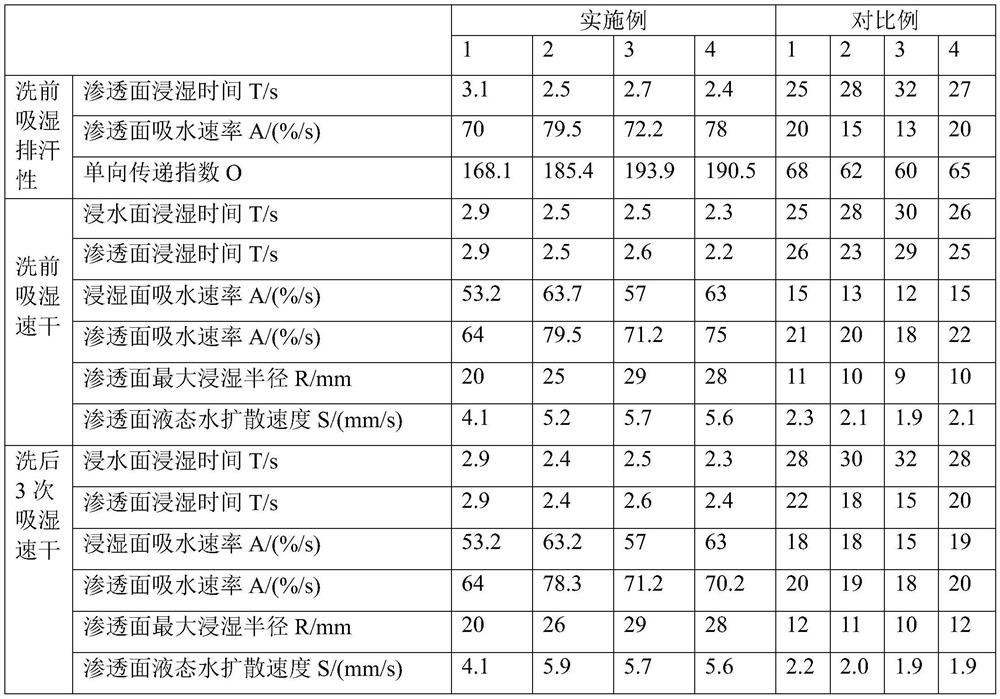

Examples

Embodiment 1

[0053] This embodiment provides a moisture-absorbing and quick-drying fabric and a preparation method thereof. The preparation method includes the steps of bleaching, dyeing, cleaning and shaping the cotton fiber fabric;

[0054] (1) The steps of blanching include:

[0055] Boil and bleach the cotton fiber fabric with the bleaching solution, add an aqueous solution of acetic acid with an acetic acid concentration of 0.9 g / L, and run at 45° C. for 5 minutes. In this step: the temperature used for bleaching and bleaching is 95°C, the time for bleaching and bleaching is 55min, and the bleaching solution contains 0.5g / L refining agent (the specific type of refining agent is JINTEX JintergEco LCF-185), 2g / L caustic And 2g / L hydrogen peroxide; the tissue fibers of cotton fabrics are all natural cotton fibers.

[0056] (2) The steps of dyeing include:

[0057] Use dye solution to dye the described cotton fiber fabric through boiling and bleaching for 20min, add sodium bicarbonate i...

Embodiment 2

[0061] This embodiment provides a moisture-absorbing and quick-drying fabric and a preparation method thereof. The preparation method includes the steps of bleaching, dyeing, cleaning and shaping the cotton fiber fabric;

[0062] (1) The steps of blanching include:

[0063] Boil and bleach the cotton fiber fabric with the bleaching solution, add an aqueous acetic acid solution with an acetic acid concentration of 1.2 g / L, and run at 55° C. for 15 minutes. In this step: the temperature used for blanching is 100°C, the duration of blanching is 65min, and the blanching liquid contains 2g / L refining agent (the specific type of refining agent is JINTEX JintergEco LCF-185), 4g / L caustic soda and 8g / L hydrogen peroxide; the tissue fibers of cotton fabrics are all natural cotton fibers.

[0064] (2) The steps of dyeing include:

[0065] Use dye solution to dye the described cotton fiber fabric through boiling and bleaching for 30min, add sodium sulfate in the dye solution and run fo...

Embodiment 3

[0069] This embodiment provides a moisture-absorbing and quick-drying fabric and a preparation method thereof. The preparation method includes the steps of bleaching, dyeing, cleaning and shaping the cotton fiber fabric;

[0070] (1) The steps of blanching include:

[0071] Boil and bleach the cotton fiber fabric with the bleaching solution, add an aqueous acetic acid solution with an acetic acid concentration of 1 g / L, and run at 50° C. for 10 minutes. In this step: the temperature used for blanching is 97°C, the duration of blanching is 60min, and the blanching liquid contains 1g / L refining agent (the specific type of refining agent is JINTEX JintergEco LCF-185), 3g / L caustic soda and 5g / L hydrogen peroxide; the tissue fibers of cotton fabrics include natural cotton fibers and artificial cotton fibers.

[0072] (2) The steps of dyeing include:

[0073] Use dye solution to dye the described cotton fiber fabric through boiling and bleaching for 25min, add sodium sulfate in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com