Water-based paste paint for rail wagons, and preparation method thereof

A railway freight car, water-based technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as atmospheric pollution and achieve the effect of improving anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

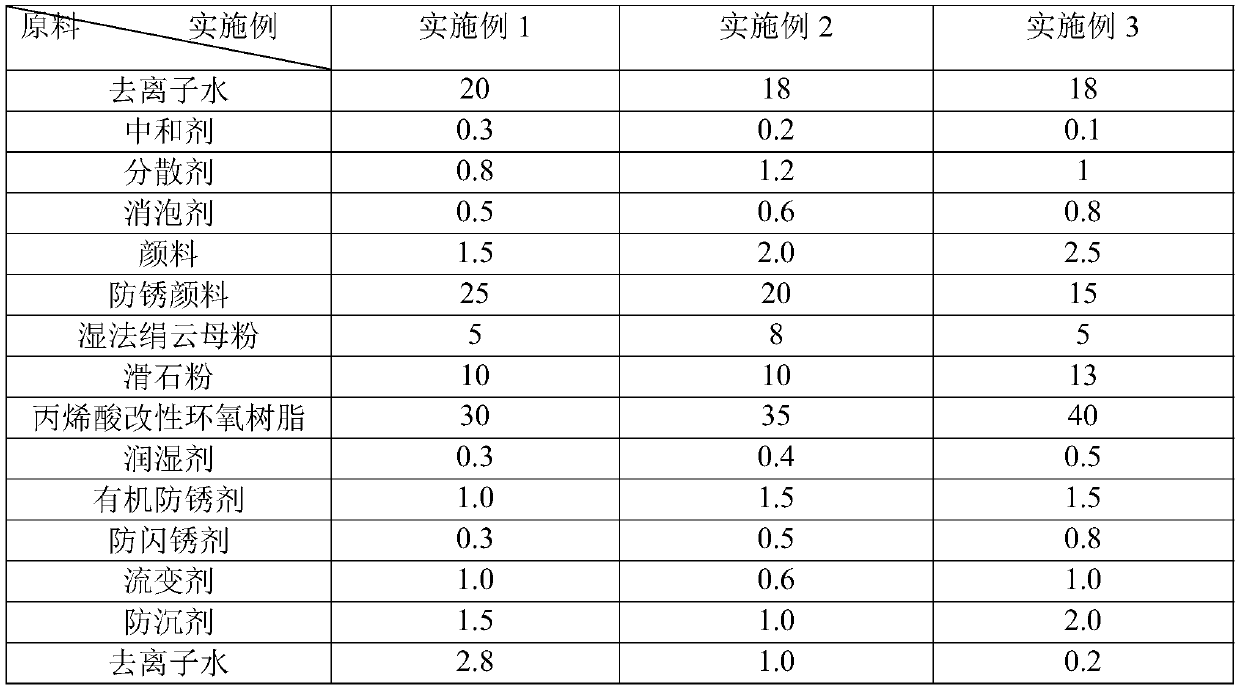

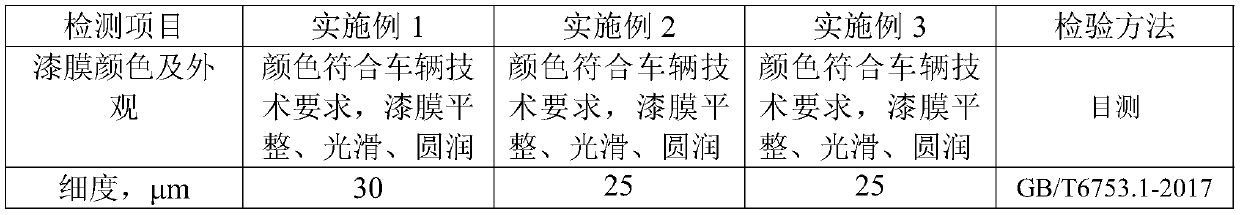

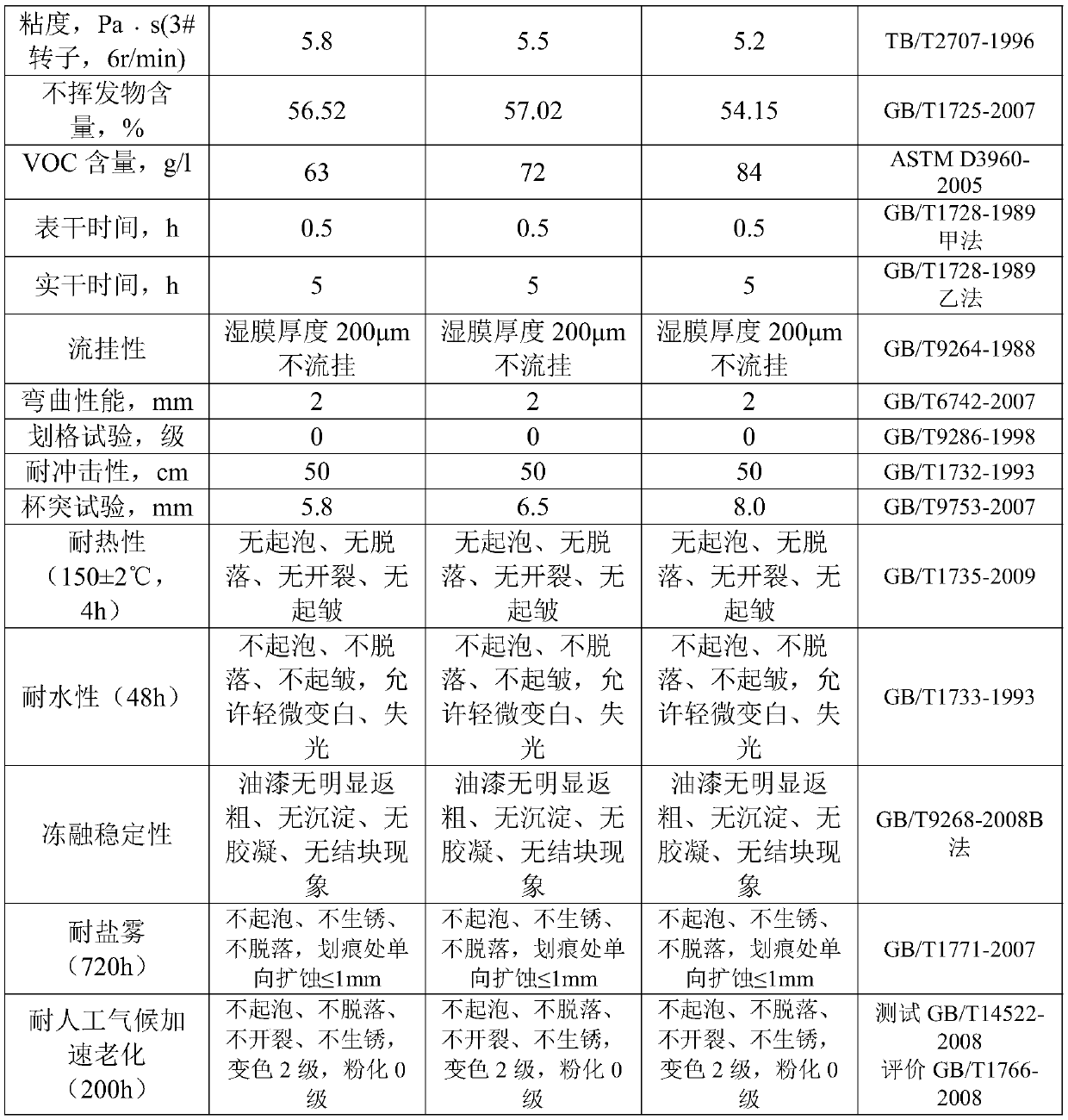

Embodiment 1-3

[0028] The raw material composition of acrylic modified epoxy resin: 25 parts of vinyl ester resin; 20 parts of ethylene glycol butyl ether; 10 parts of butyl acrylate; 5 parts of methyl methacrylate; 2 parts of vinyl trimethoxysilane; 6 parts of triethylamine; 0.1 part of BPO; 27.9 parts of deionized water.

[0029] The preparation method of above-mentioned acrylic acid modified epoxy resin:

[0030] (a) Mix butyl acrylate, methyl methacrylate, vinyltrimethoxysilane, acrylic acid, and BPO evenly to obtain an acrylic acid monomer mixture, which is set aside;

[0031] (b) Add vinyl ester resin into the reactor, add ethylene glycol butyl ether, raise the temperature to 100-120°C, add the acrylic acid monomer mixture dropwise in 2 hours, and keep it warm for 2 hours;

[0032] (c) Cool down to room temperature, add triethylamine for neutralization, and obtain an acrylic modified epoxy resin.

[0033] The prepared acrylic modified epoxy resin is applied to the water-based high-bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com