Three-proofing school uniform and making method thereof

A production method and technology for school uniforms, applied in the field of clothing, can solve the problems of not having the "three defenses" (waterproof, oil-proof, anti-fouling, moisture absorption, breathable, elastic and non-irritating, hygienic, and antibacterial). The anti-proof effect is enhanced, the three-proof effect is good, and the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

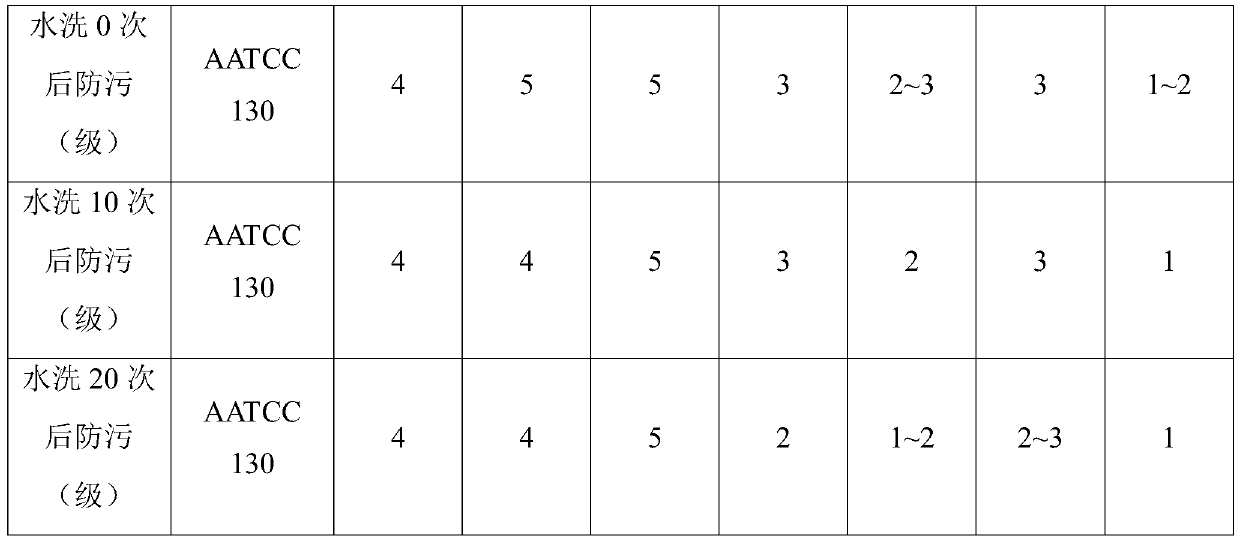

[0036] Example 1: A three-proof school uniform, the three-proof school uniform is made of three-proof fabric; the three-proof fabric is blended with composite fiber A and composite fiber B, and is obtained after finishing with a compound three-proof finishing agent; The composite fiber A includes the following raw materials by weight: 82 to 95 parts of cotton fiber, 5 to 16 parts of asparagus fiber, and 4 to 12 parts of superfine pearl powder; the composite fiber B includes the following raw materials by weight: polyurethane fiber 25 ~35 parts, 45~60 parts of polyester fiber, 8~14 parts of asparagus fiber, 1~2.2 parts of fatty alcohol ether phosphate potassium salt, 1.5~3.5 parts of dandelion extract; the compound three-proof finishing agent includes The raw materials are as follows in parts by weight: 45-55 parts of Oliver SLA-NEW three-proof finishing agent, 2-3.5 parts of fatty alcohol polyoxyethylene ether, 48-60 parts of nano zinc oxide dispersion liquid, and 0.6-0.9 parts...

Embodiment 2

[0052] Embodiment 2: A three-proof school uniform, the three-proof school uniform is made of three-proof fabric; the three-proof fabric is blended with composite fiber A and composite fiber B, and is obtained after finishing with a compound three-proof finishing agent; The composite fiber A includes the following raw materials by weight: 82 parts of cotton fiber, 5 parts of asparagus fiber, and 4 parts of superfine pearl powder; the composite fiber B includes the following raw materials by weight: 25 parts of polyurethane fiber, 45 parts of polyester fiber 8 parts of asparagus fiber, 1 part of fatty alcohol ether phosphate potassium salt, and 1.5 parts of dandelion extract; the compound three-proof finishing agent includes the following raw materials in parts by weight: Ori Fluoro SLA-NEW three-proof finishing 45 parts of agent, 2 parts of fatty alcohol polyoxyethylene ether, 48 parts of nanometer zinc oxide dispersion liquid, 0.6 part of citric acid.

[0053] In Example 2, th...

Embodiment 3

[0063] Embodiment 3: A kind of three-proof school uniform, the three-proof school uniform is made of three-proof fabric; the three-proof fabric is made of composite fiber A and composite fiber B blended, and is obtained after finishing with a compound three-proof finishing agent; The composite fiber A includes the following raw materials by weight: 95 parts of cotton fiber, 16 parts of asparagus fiber, and 12 parts of superfine pearl powder; the composite fiber B includes the following raw materials by weight: 35 parts of polyurethane fiber, 60 parts of polyester fiber 14 parts, 14 parts of asparagus fiber, 2.2 parts of fatty alcohol ether phosphate potassium salt, 3.5 parts of dandelion extract; the compound three-proof finishing agent includes the following raw materials in parts by weight: Oliver SLA-NEW three-proof finishing 55 parts of agent, 3.5 parts of fatty alcohol polyoxyethylene ether, 60 parts of nano-zinc oxide dispersion, and 0.9 part of citric acid.

[0064] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com