Efficient plastic runway paver and plastic runway paving method thereof

A plastic runway and paver technology, applied in roads, roads, road repairs, etc., can solve the problems of insufficient paving effect of paver, too much or too little paving, and limiting the speed of plastic runway paving, etc. Achieve good paving effect, speed up paving speed and improve paving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

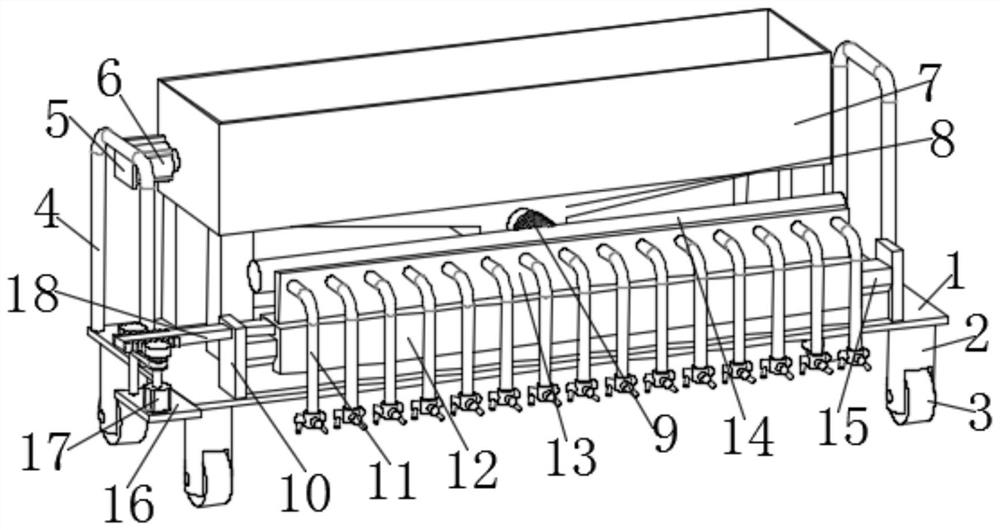

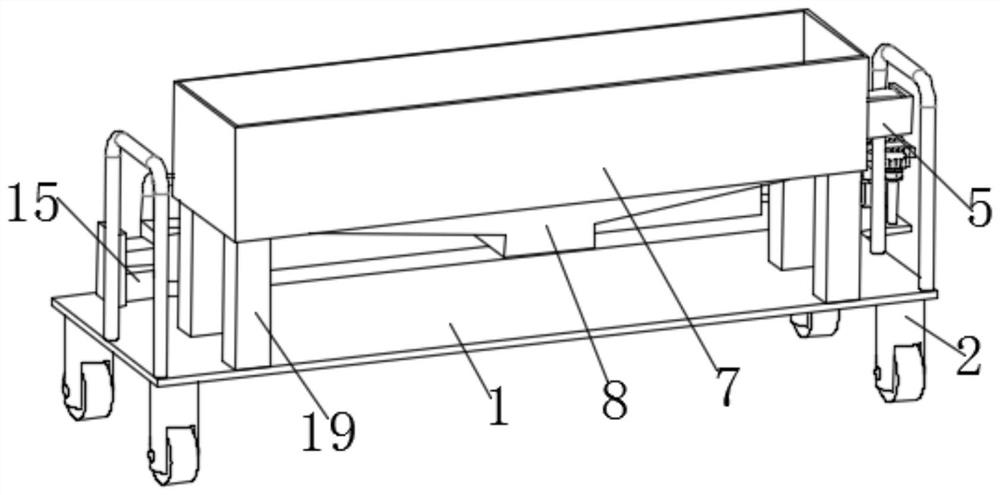

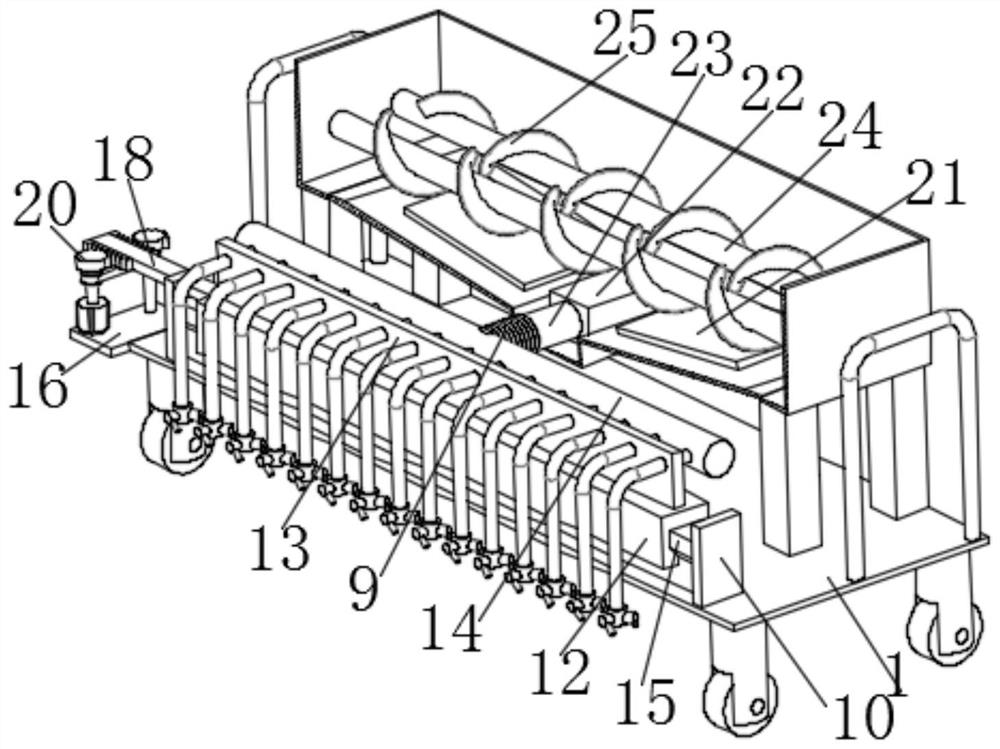

[0043] Example: Reference Figure 1-8 A kind of high-efficiency plastic runway paver shown comprises base 1, and the top of base 1 is fixedly equipped with slide rail 15, four columns 19, and column 19 can be any metal bar in the prior art, and it and base 1 is fixed by welding at the top. Slide rail 15 is slidably sleeved with sliding seat 12, and the tops of four columns 19 are fixedly installed with the same raw material box 7, and raw material box 7 can be any metal box in the prior art, and it is welded with the top of column 19 to fix. Raw material uniform mixing part is installed on raw material box 7, and the bottom of raw material box 7 is provided with slide material hole, and useful hopper 8 is fixedly installed on the inwall of slide material hole, and useful hopper 8 can be any metal shell in the prior art, It is fixed by welding with the inner wall of the sliding material hole. A pump body 22 is fixedly installed on the top inner wall of the hopper 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com