Material flattening device for straw board production

A straw board and material technology, which is applied in the field of straw board production equipment, can solve the problems of inconvenient paving and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

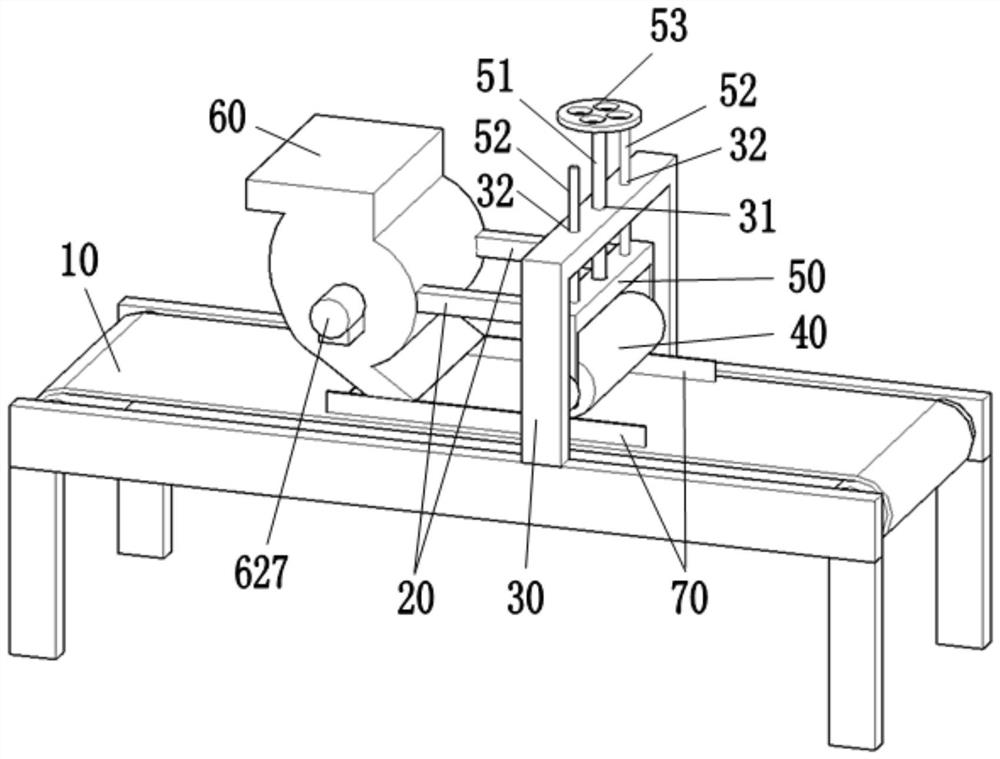

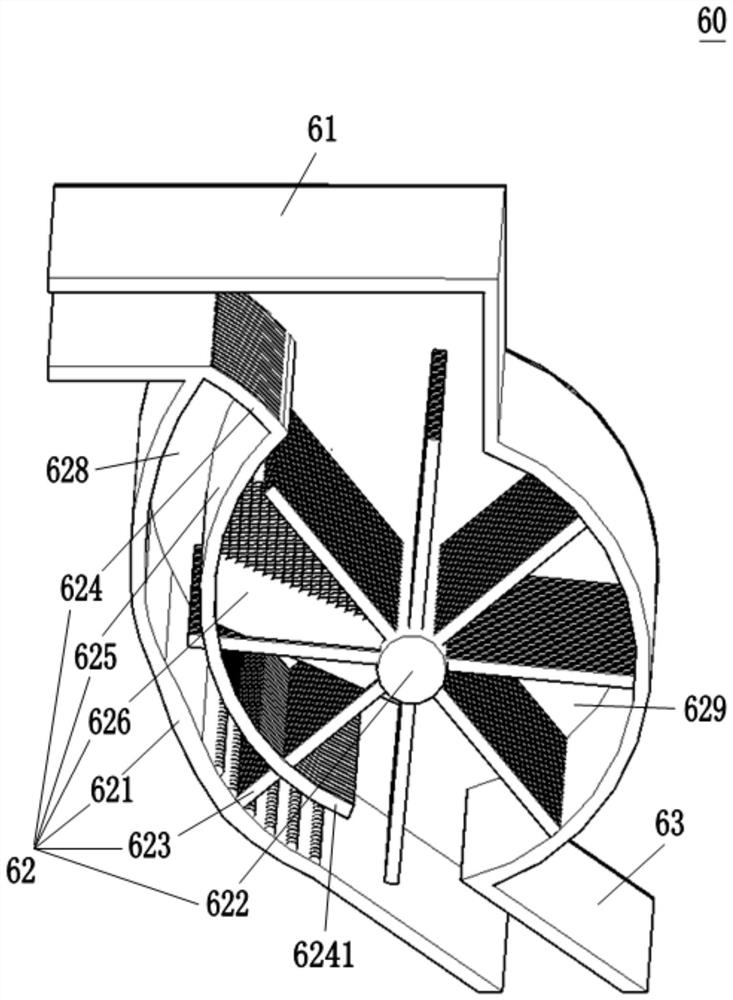

[0020] Such as figure 1 , figure 2 As shown, a material leveling device for straw plate production includes: conveyor 10, support arm 20, gantry frame 30, electric roller 40, mobile support 50, distributor 60, baffle 70, wherein the conveyor The running direction of 10 is from left to right, the gantry 20 spans and is fixed above the conveyor 10, the mobile bracket 50 is installed on the gantry 20, and the distributor 60 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com