Corrugated steel web beam combined joint structure and assembly method

A technology of corrugated steel webs and corrugated webs, applied in building construction, construction, etc., can solve problems such as damage, difficulty in post-earthquake repairs, fracture and tearing of connections at welds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

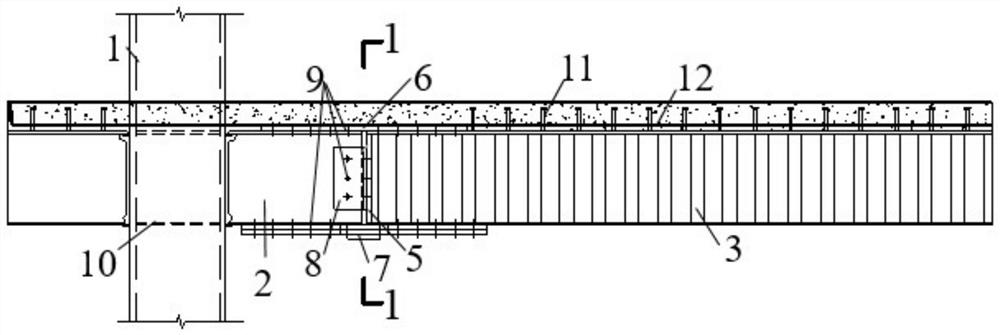

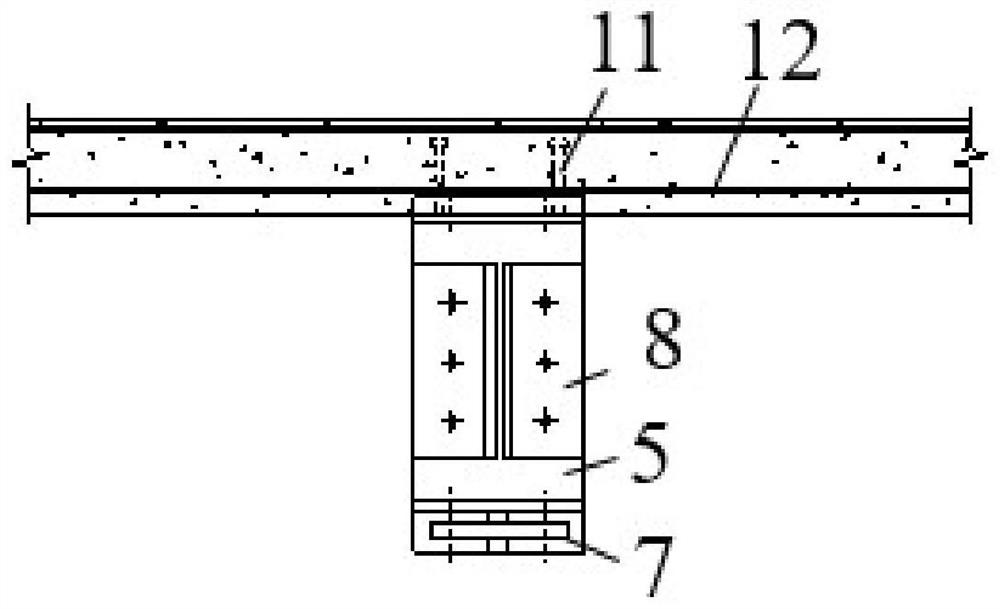

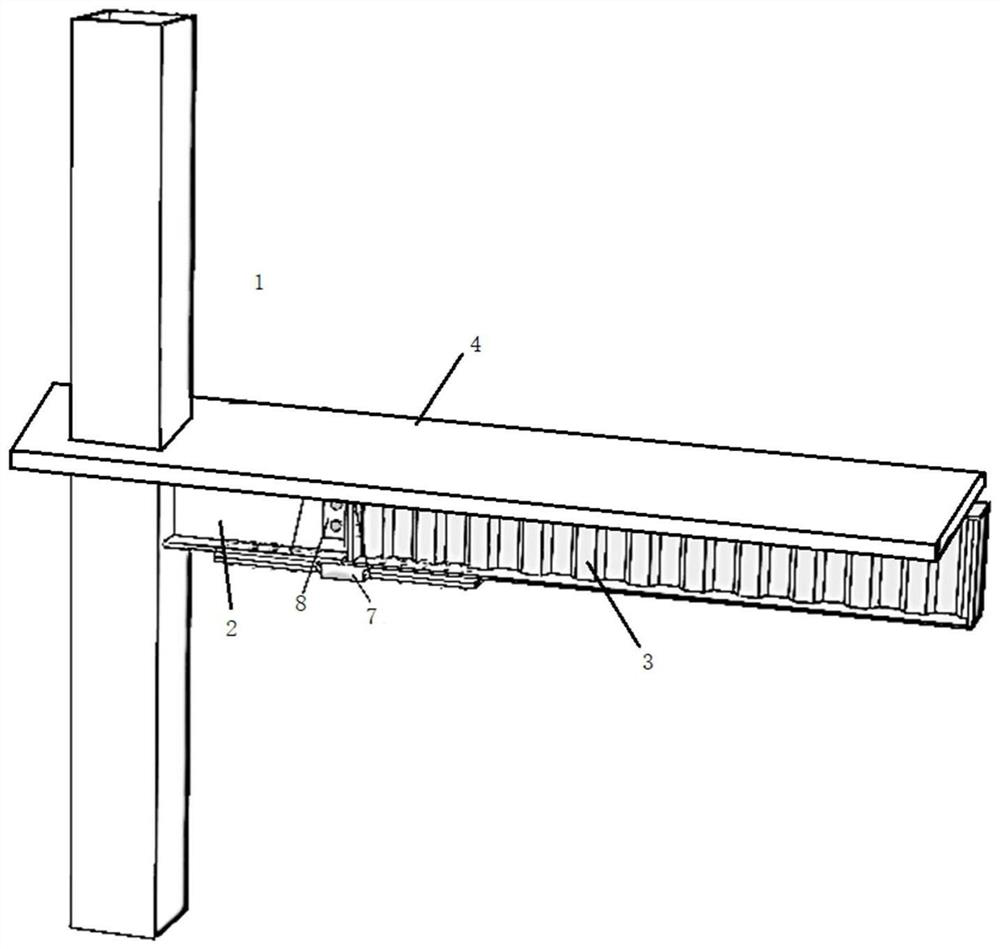

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033] like Figure 1 to Figure 3 As shown, a corrugated steel web beam composite node structure includes a box column 1, a transition connecting beam 2, a corrugated web steel beam 3 and a concrete slab 4, and the transition connecting beam 2 and the corrugated web steel beam 3 are both H-shaped structure, the web of the corrugated web steel beam 3 is a corrugated web, one end of the transition connecting beam 2 is fixedly connected to the side wall of the box column 1, and the other end of the transition connecting beam 2 passes through one end of the corrugated web steel beam 3 The buckling restraint plate 7 is fixedly connected; the concrete plate 4 is fixedly connected with the transition connecting beam 2 and the upper end of the corrugated web steel beam 3 through shear bolts 11, and the upper end of the corrugated web steel beam 3 is poured to form the concret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com