Combined piston type liquid propellant storage tank

A liquid propellant and combined piston technology, applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of low emptying efficiency, low space utilization, and heavy weight, and achieve tight gas-liquid isolation, Light weight and improved internal space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

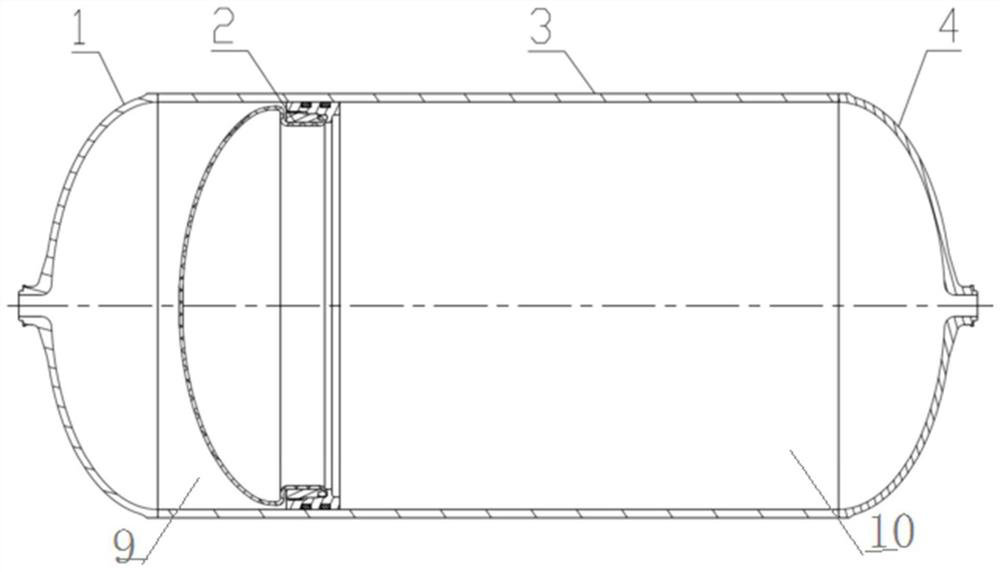

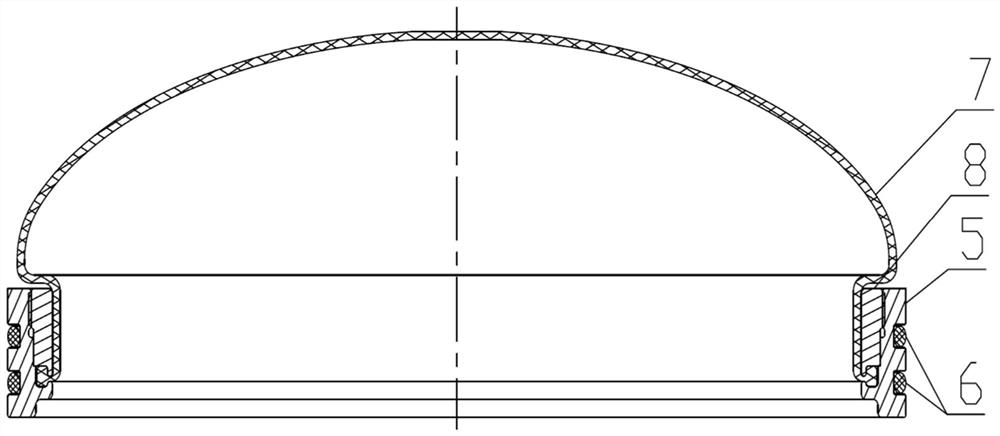

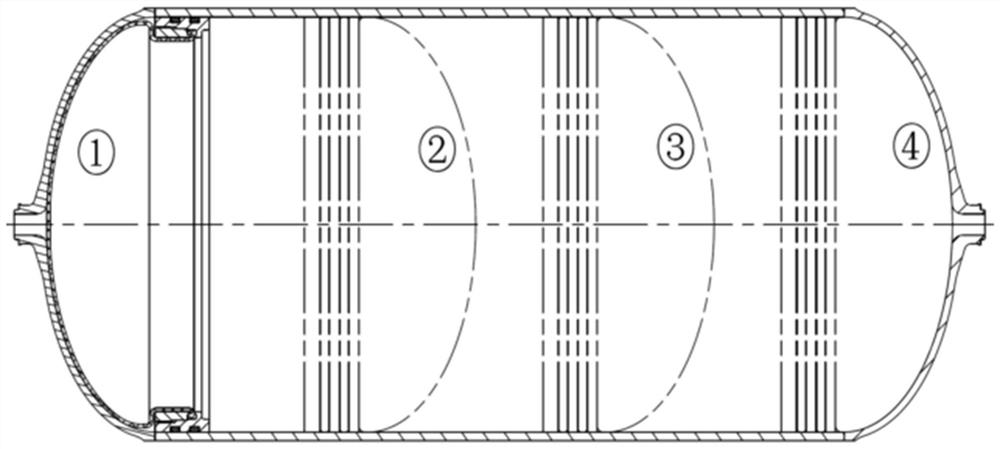

[0026] Such as figure 1 As shown, a combined piston type liquid propellant storage tank is composed of an air chamber head 1, a combined piston assembly 2, a cylinder body 3, and a liquid chamber head 4; an air chamber head 1, a cylinder body 3, and a liquid chamber The head 4 is made of the same metal material and welded from left to right to form a closed cavity. The metal material can be titanium alloy, aluminum alloy or stainless steel; the combined piston assembly 2 is assembled in the inner cylinder of the closed cavity On the surface of the body 3, it can be located at any position inside the cylinder; the left side surface of the combined piston assembly 2 forms an air cavity space 9 between the cylinder body 3 and the air cavity head 1, and the right side surface of the combined piston assembly 2 A closed liquid chamber space 10 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com