Multi-stage sleeve type high-pressure-difference control valve sleeve structure and design optimization method

A technology for controlling valve sleeves and optimization methods, which can be used in design optimization/simulation, computer-aided design, calculation, etc. Good steady flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

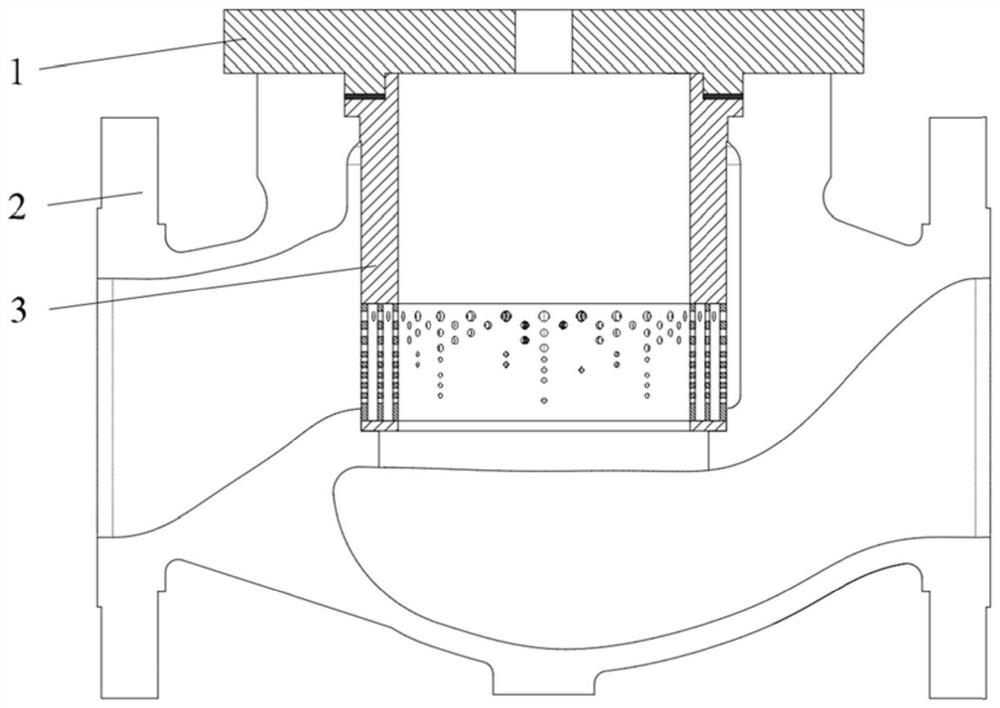

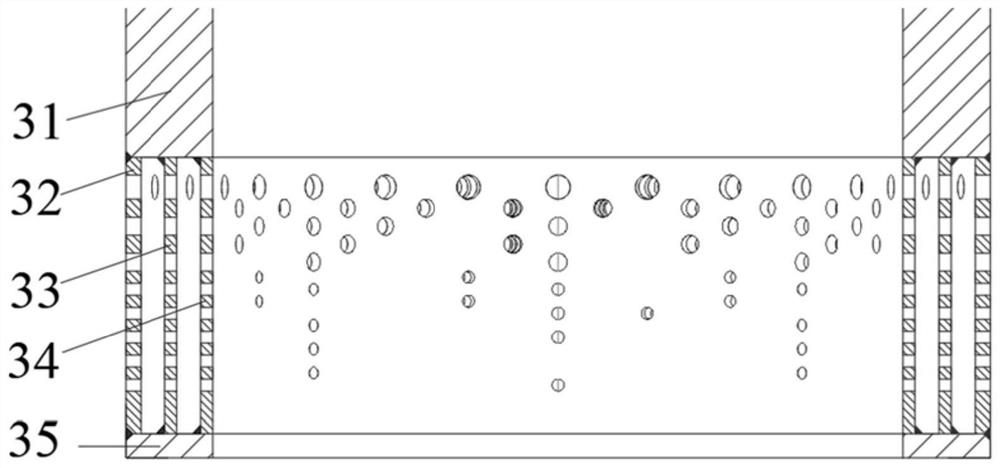

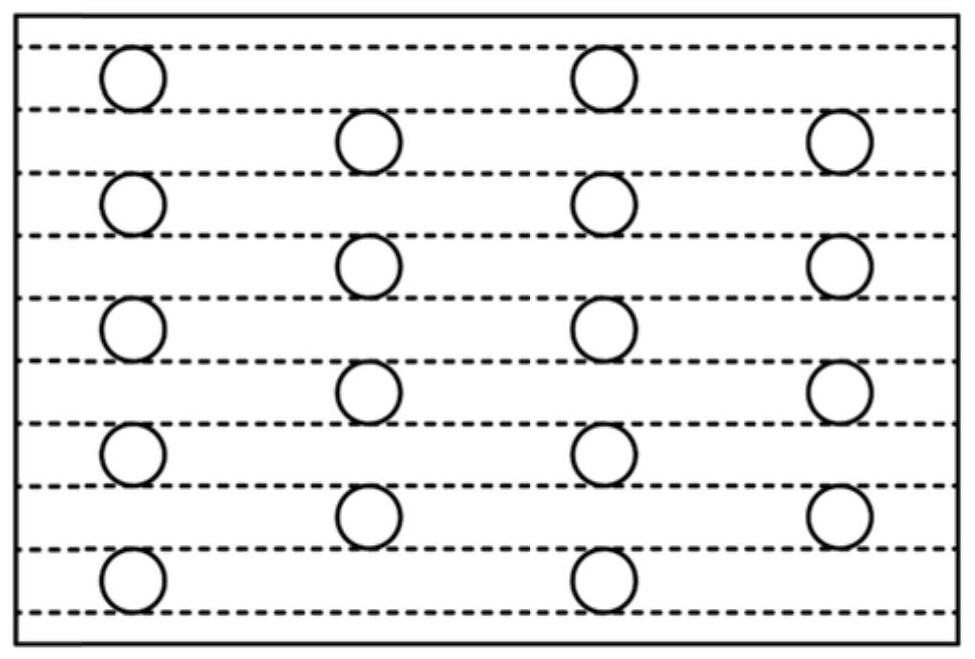

[0047] Such as figure 1As shown, it is a multi-stage sleeve type high pressure differential control valve structure, which mainly includes a valve cover 1, a valve body 2 and a sleeve assembly 3. The sleeve structure of the multi-stage sleeve type high pressure differential control valve of the present invention is the sleeve assembly 3 arranged between the valve cover 1 and the valve body 2 . The sleeve assembly 3 is located in the valve body 2 as a whole, including an upper sleeve 31 , a perforated sleeve and a lower bottom 35 of the sleeve. Wherein the sleeve has multiple layers, and the total number of sleeve layers is the sleeve series. The multi-layer sleeves are coaxially nested, and the tops are all connected to the bottom of the upper sleeve 31, and the bottoms are all blocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com