Universal self-sealing joint for pipeline

A self-sealing and pipeline technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve problems such as sealing oil leakage, poor high temperature resistance, and contamination of circulating media in pipelines, and achieve installation Convenience and the effect of ensuring axial rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

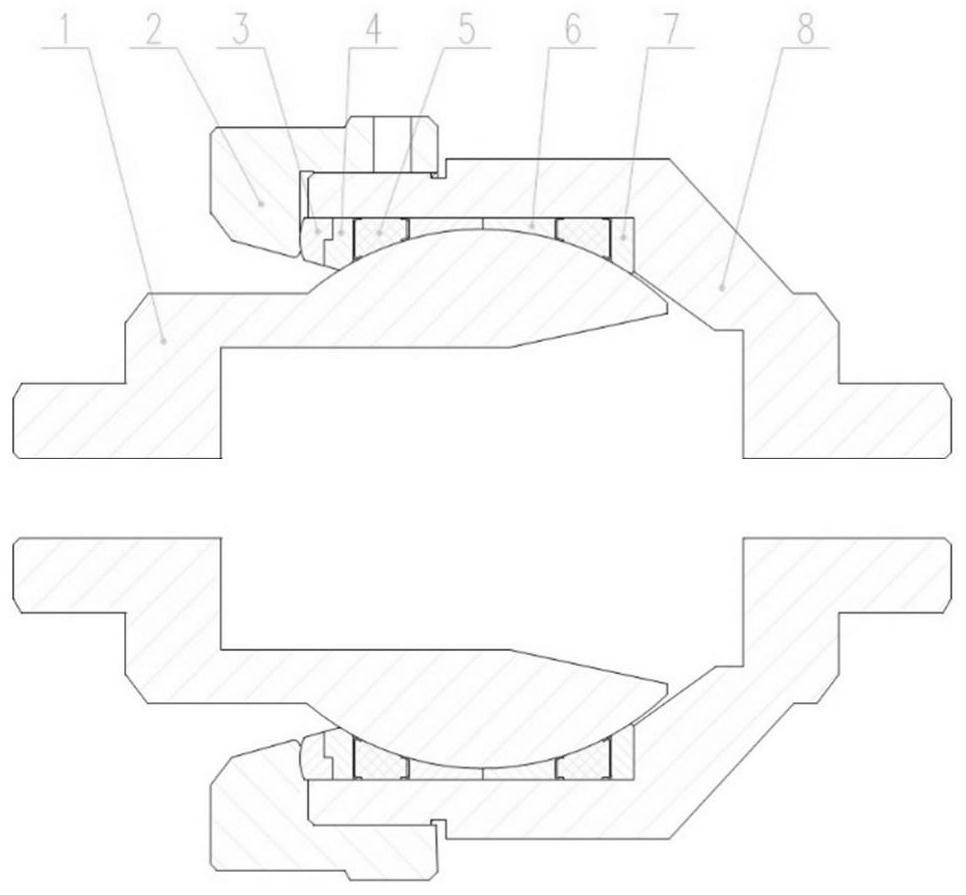

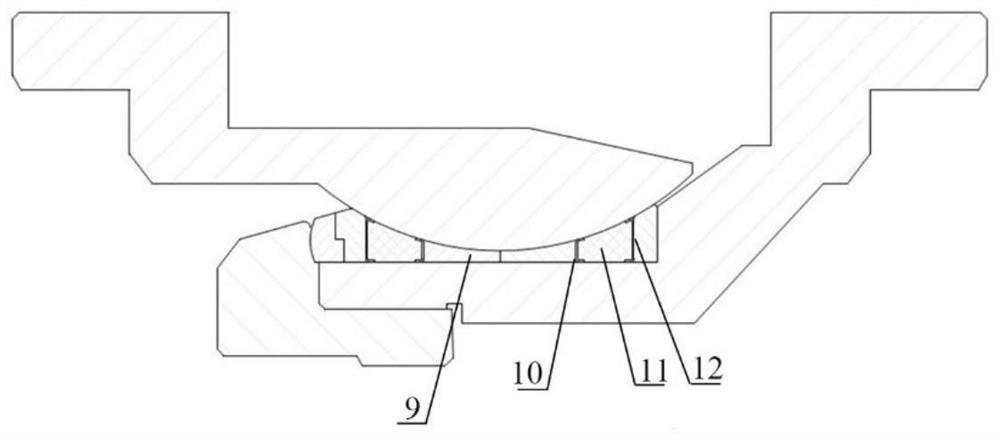

[0032] A pipeline universal self-sealing joint, comprising a ball joint body 1, a nut 2, a joint body 8 and a sealing assembly; wherein the ball joint body 1, the nut 2 and the joint body 8 form a sealed space, and the sealed space A sealing assembly is installed inside, the nut 2 and the joint body 8 are connected by threads, and a bevel is set between the nut 2 and the ball joint body 1 so that the ball joint body 1 can tilt and swing in the axial direction; the seal assembly runs along the ball joint to the joint The body direction includes in turn: adjusting ring 1 3, adjusting ring 2 4, sealing ring 1 5, lining ring 1 9, lining ring 2 6, sealing ring 2, and adjusting ring 3 7.

[0033] Preferably, the side of the adjusting ring 1 3 and the adjusting ring 2 4 close to the ball joint body 1 has the same inclination angle as the bevel, and the inclination angle is 15-20°, preferably 15.5°.

[0034] Preferably, the adjusting ring one 3 and the adjusting ring two 4 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com