High-precision belt pulley run-out testing fixture

A pulley, high-precision technology, used in measuring devices, instruments, mechanical devices, etc., can solve the problems of poor repeatability of beating results, high space occupation requirements, low measurement adaptability, etc., to save measurement costs, small space occupation, The effect of high accuracy of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

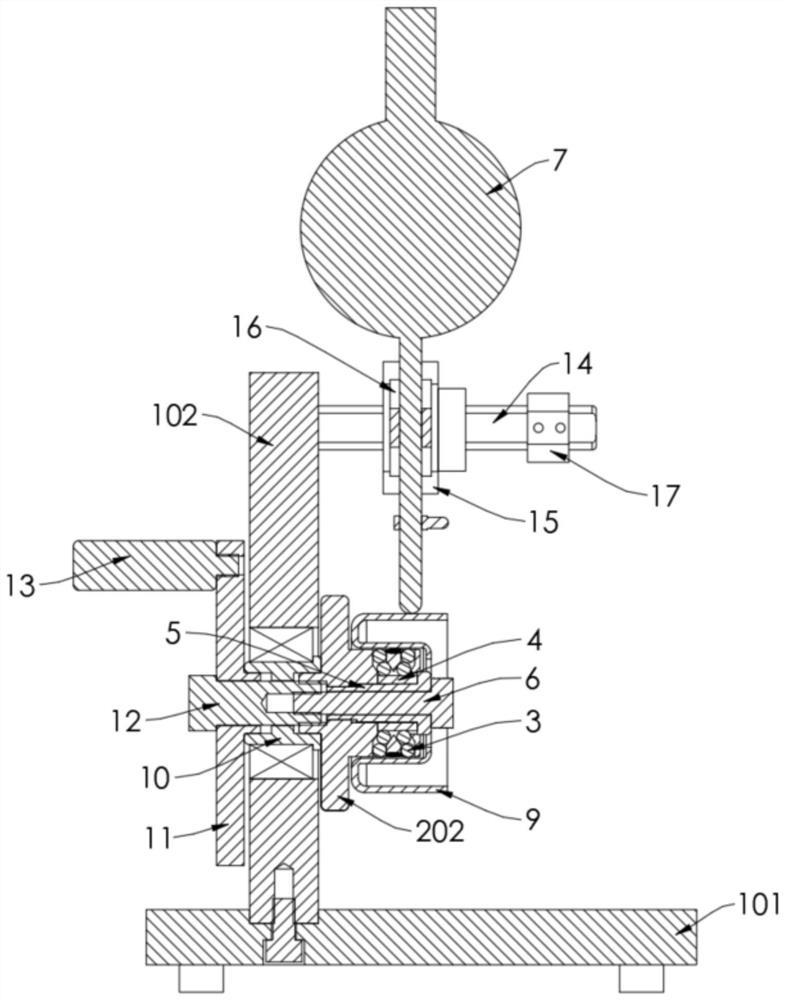

[0039] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

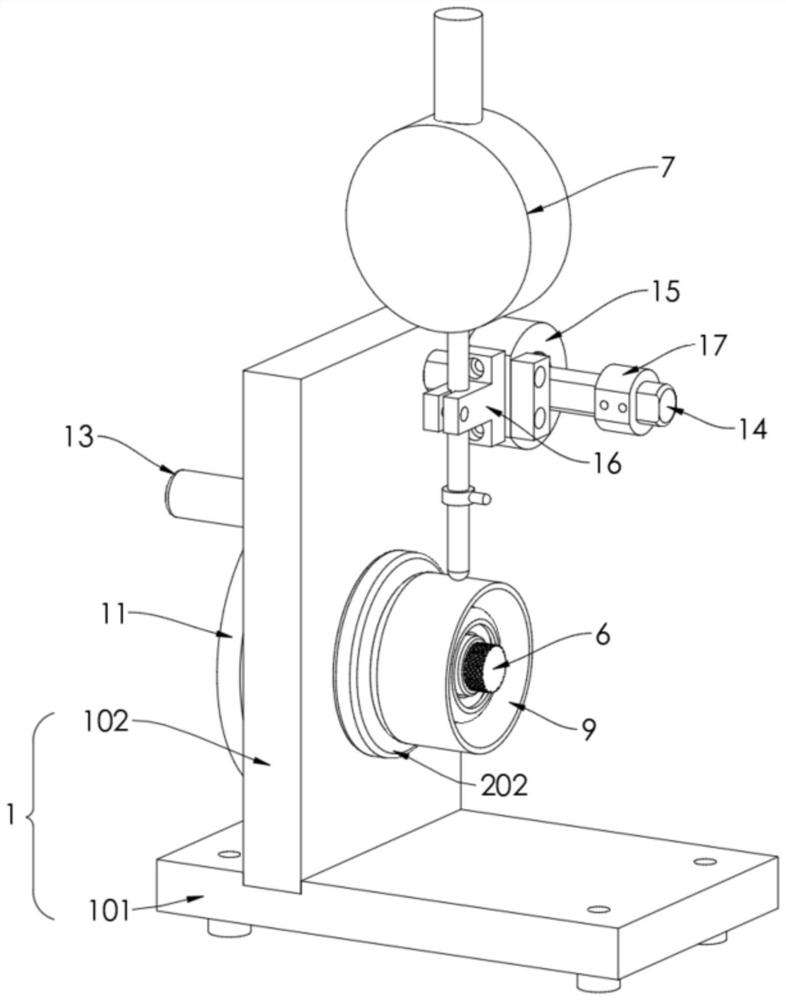

[0040] refer to Figure 1-5 , a high-precision pulley runout tester, including

[0041]mount 1;

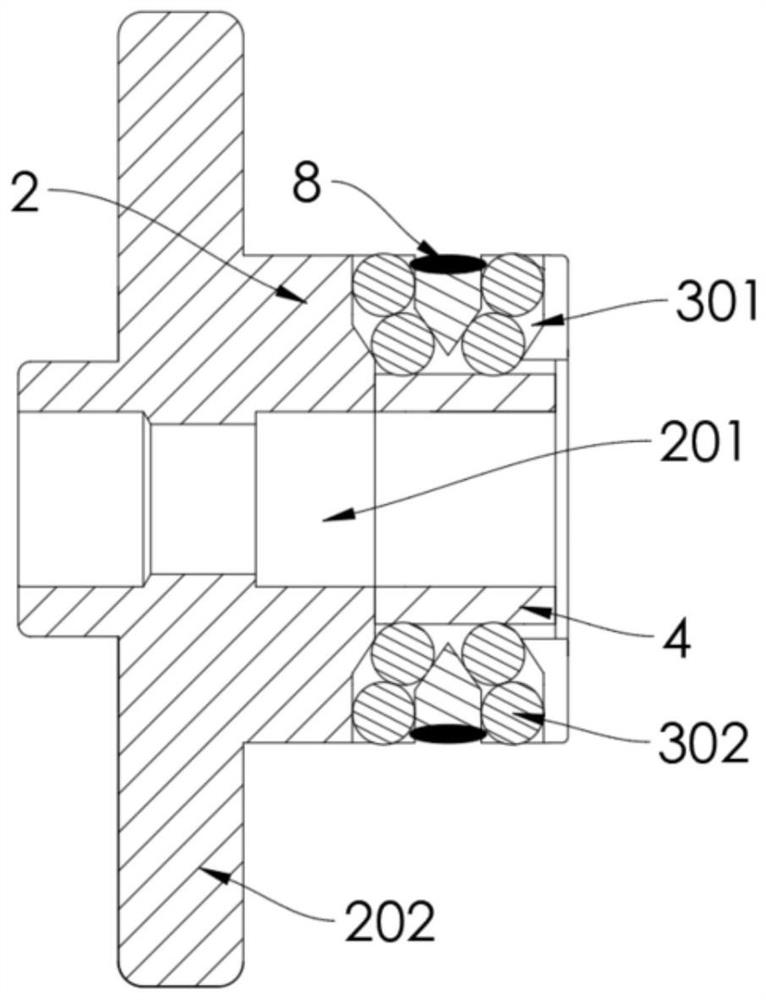

[0042] The workpiece mounting block 2 is rotatably mounted on the mounting seat 1, and the middle part of the workpiece mounting block is provided with a corresponding mounting hole 201;

[0043] The abutment mechanism 3 includes several groups of fixing holes 301 arranged on the workpiece mounting block 2, each group of fixing holes 301 is two, the bottom of the fixing holes 301 is inclined inwardly, and the upper part of the fixing holes 301 is vertical upward It is provided that two corresponding abutment balls 302 are respectively movably installed in the fixing holes 301, and the two abutment balls 302 are respectively placed at the bottom and upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com