Generator stator fault monitoring method and device based on strain and sound wave sensing

A generator stator and fault monitoring technology, which is applied in the direction of measuring devices, optical devices, and processing detection response signals, can solve the problems of failure identification and early warning of generator stator faults, and achieve the effect of saving sensor costs and optimizing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

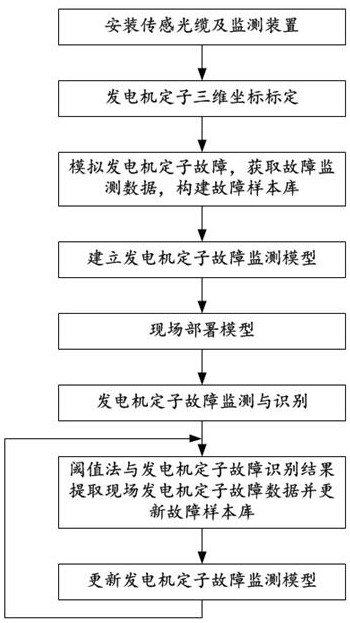

[0078] Such as Figure 1 to Figure 10 As shown, the method of generator stator fault monitoring based on strain and acoustic wave sensing includes the following steps:

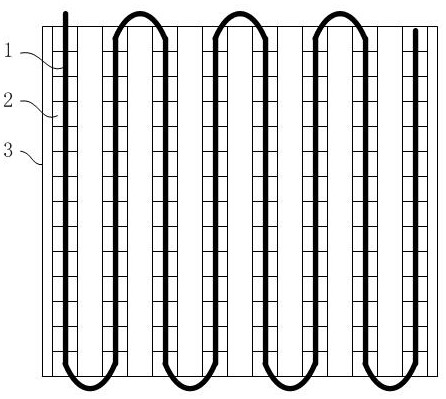

[0079] S100. Installing the sensing optical cable used for measuring the stator strain and the acoustic signal of the large-scale generator: the sensing optical cable 1 is sequentially wound and installed in all the stator slots 2 of the large-scale generator in a serpentine manner, and the sensing optical cable is wound from the stator winding 3 The end is led out and connected to the optical fiber distributed strain / acoustic sensor demodulator, which is used to demodulate the strain contained in the sensing cable and the scattered light signal of the acoustic wave Send it to the host computer for signal processing; install and fix the sensing optical cable along the stator slot in the forward direction, bypass the end of the stator slot and then install and fix it in the adjacent stator slot until the sensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com