Detection device for tensile test of bridge steel strand

A technology of tensile testing and detection devices, which is applied in the field of bridge steel strands, can solve problems such as the inability to detect the strength and elongation of steel strands, and the inability to guarantee data rigor, so as to increase diversity, increase fault tolerance, and ensure rigor sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

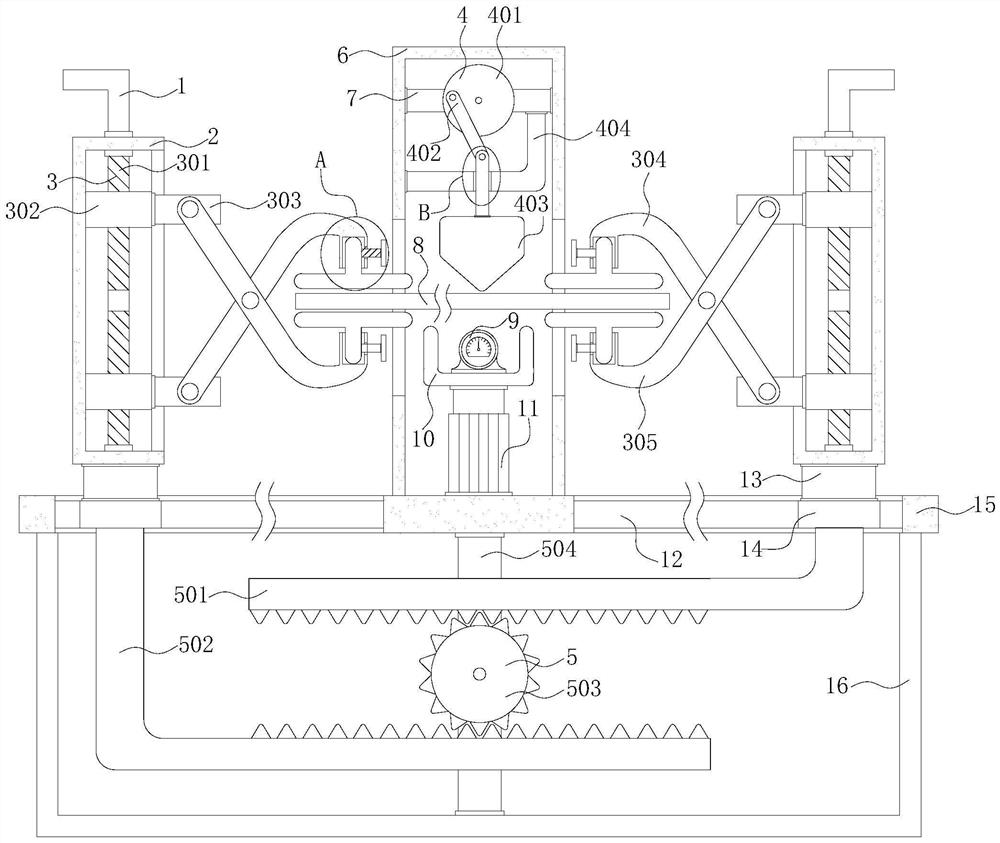

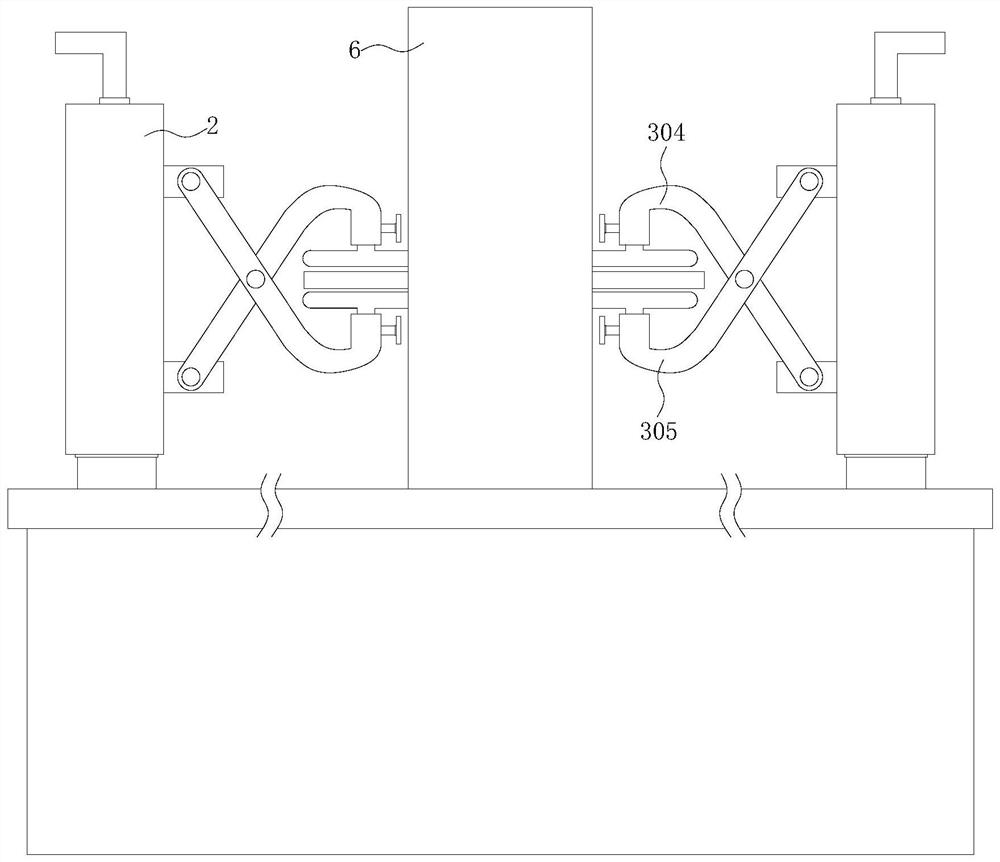

[0025] see Figure 1-6 , the present invention provides a technical solution: a bridge steel strand tensile test detection device, including a top plate 15, the bottom of the top plate 15 is welded with a U-shaped box 16, and the top of the top plate 15 is welded with a hydraulic rod 11 and a U-shaped box. U-shaped placement box 6, the U-shaped placement box 6 covers the hydraulic rod 11 inside, and the top of the top plate 15 is provided with a traverse groove 12. side, the inside of the two traversing grooves 12 is slidingly installed with a traversing block 14, the top of the traversing block 14 is welded with a fixed block 13, the top of the fixed block 13 is welded with a side frame 2, and the side frame 2 A rotary clamping and positioning mechanism 3 is arranged inside.

[0026] The rotary clamping positioning mechanism 3 includes a two-way threaded rod 301, a moving block 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com