Coal mining machine electrical assembly detection test bench

An electrical component, electromechanical technology, which is applied in the field of coal shearer electrical component testing test benches, can solve the problem that the testing test bench does not have special environmental testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

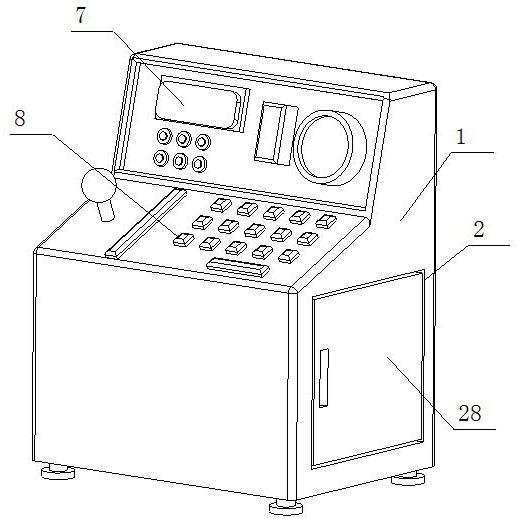

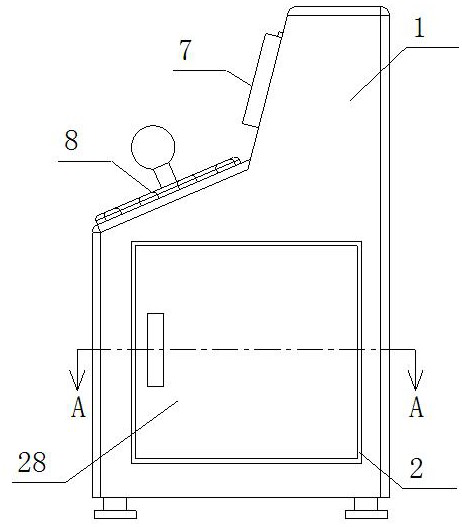

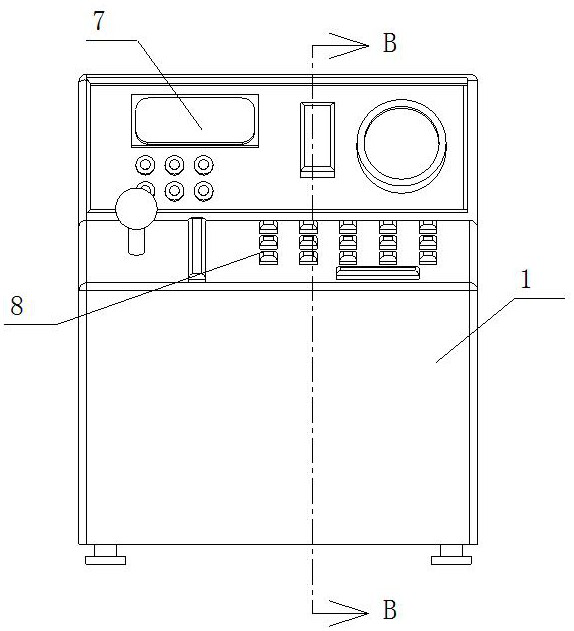

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-Figure 5 As shown, the embodiment of the present invention is a coal shearer electrical component detection test bench, including a platform body 1, and the interior of the platform body 1 is provided with a storage space 2 that can simulate the temperature and humidity changes in the daily working state of the coal mining machine. The storage space 2 The electrical components of the shearer are placed inside, and the interior of the storage space 2 is provided with a detection interface 3 for electrical connection with the electrical components of the shearer, and the EPU (intelligent energy-saving processor) of the electrical components of the shearer is connected through the detection interface 3 The module, the motor controller module and the ground leakage blocking module are used to detect changes with temperature and humidity.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com