Corrosion-resistant coating and preparation method thereof

A corrosion-resistant and coating technology, applied in chemical instruments and methods, dissolving, grain processing, etc., can solve problems such as inconvenient refinement of coating materials, avoid jitter and stress concentration, maintain stability, and reduce refinement problems. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

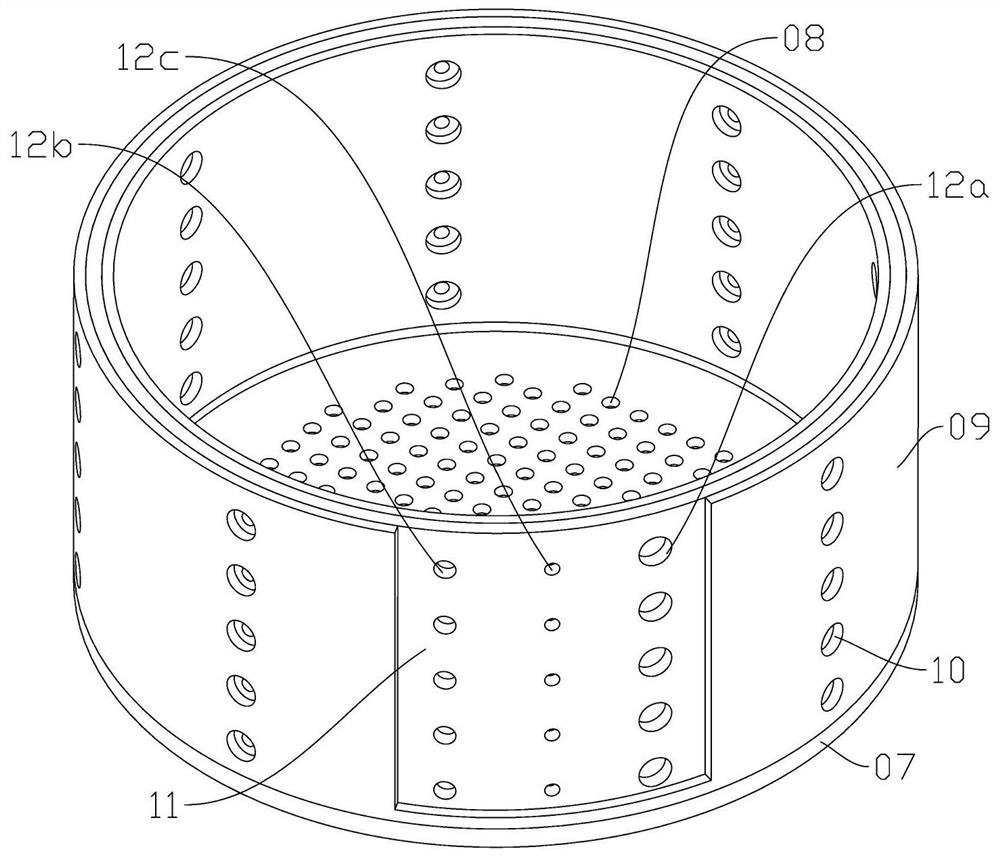

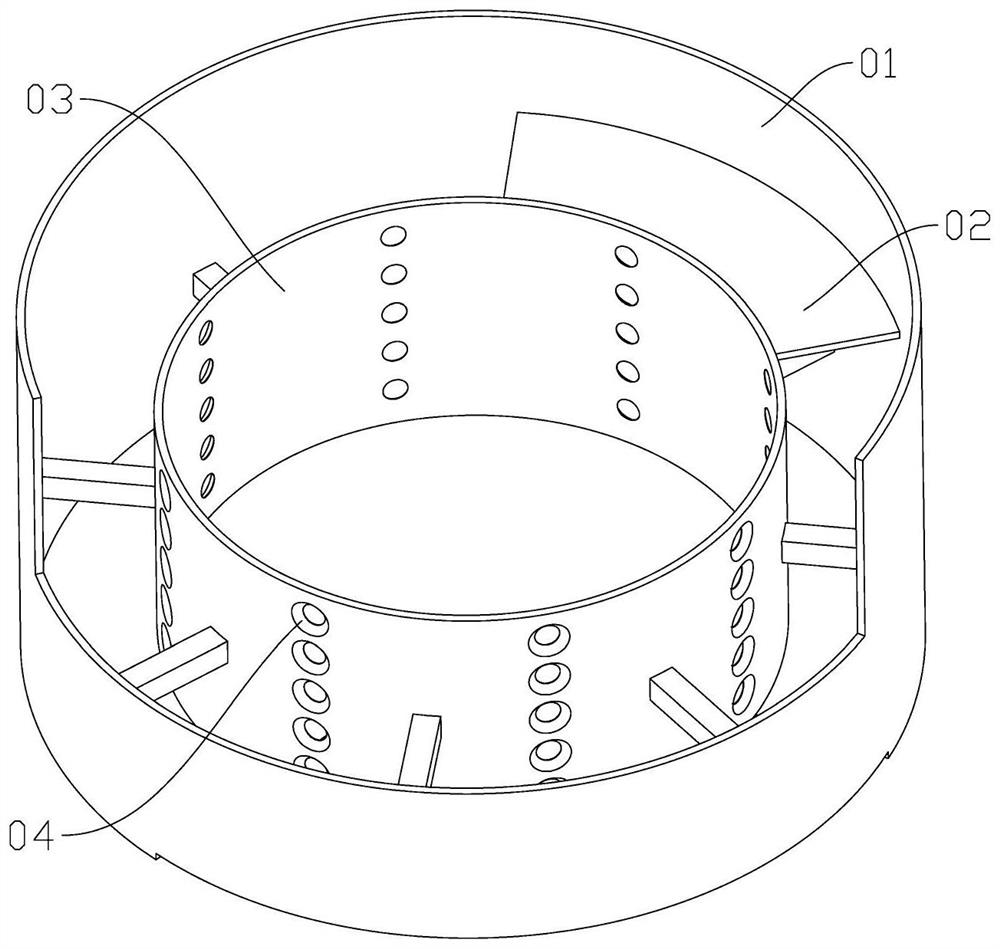

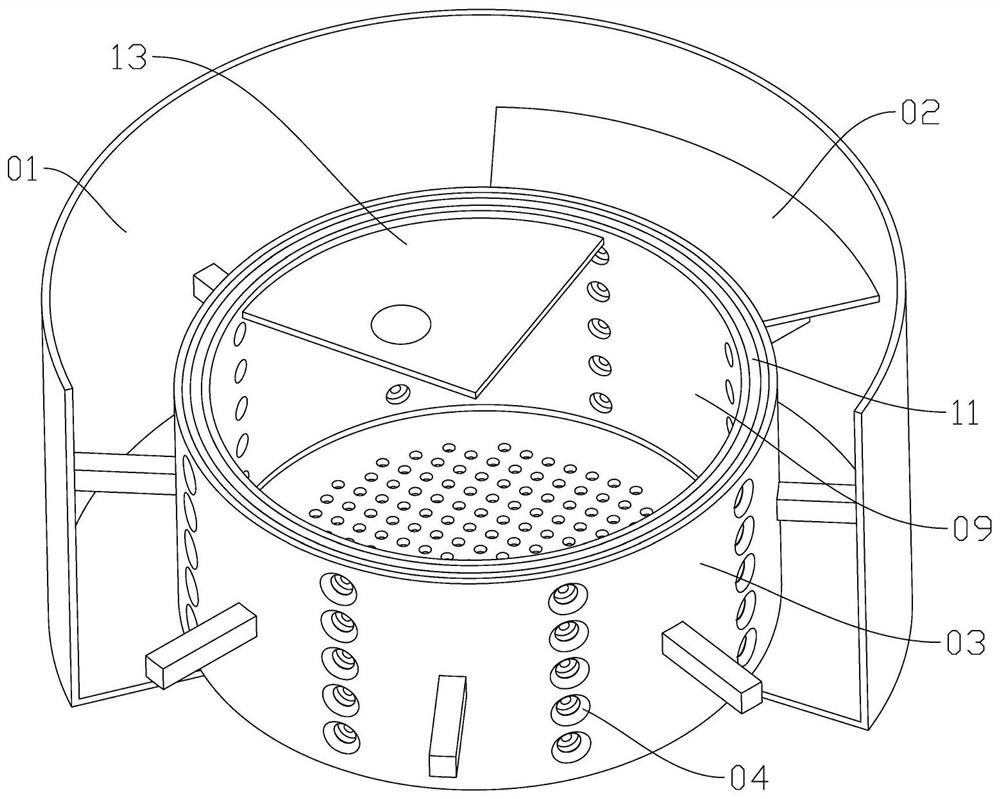

[0056] With reference to the accompanying drawings in the embodiments of the present invention, the thinning device used in the present invention will be described in detail.

[0057] The invention provides a method for preparing a corrosion-resistant paint, comprising the following steps:

[0058] Step 1: Put the coating material into the intercepting part of the refining device, and control the rotating of the intercepting part to fully mix the small particles and the fluid material before throwing them out;

[0059] Step 2: Scatter the large-grained paint material by rotating the retaining part in positive and negative cycles;

[0060] Step 3: When the retention part is bonded to the bottom of the storage part, the retention part is rotated to grind and refine the paint material.

[0061] As a further improved technical scheme of the present invention, see figure 1 :

[0062] By rotating the intercepting part in positive and negative cycles, the large-grained paint mater...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap