Centrifugal efficient sand crushing device for nodular cast iron

A ductile iron, centrifugal technology, used in centrifuges, grain processing and other directions, can solve the problems of incomplete fragmentation, easy retention of sand blocks, noise damage to human health, etc., to improve service life, improve mixing effect, crush sand Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

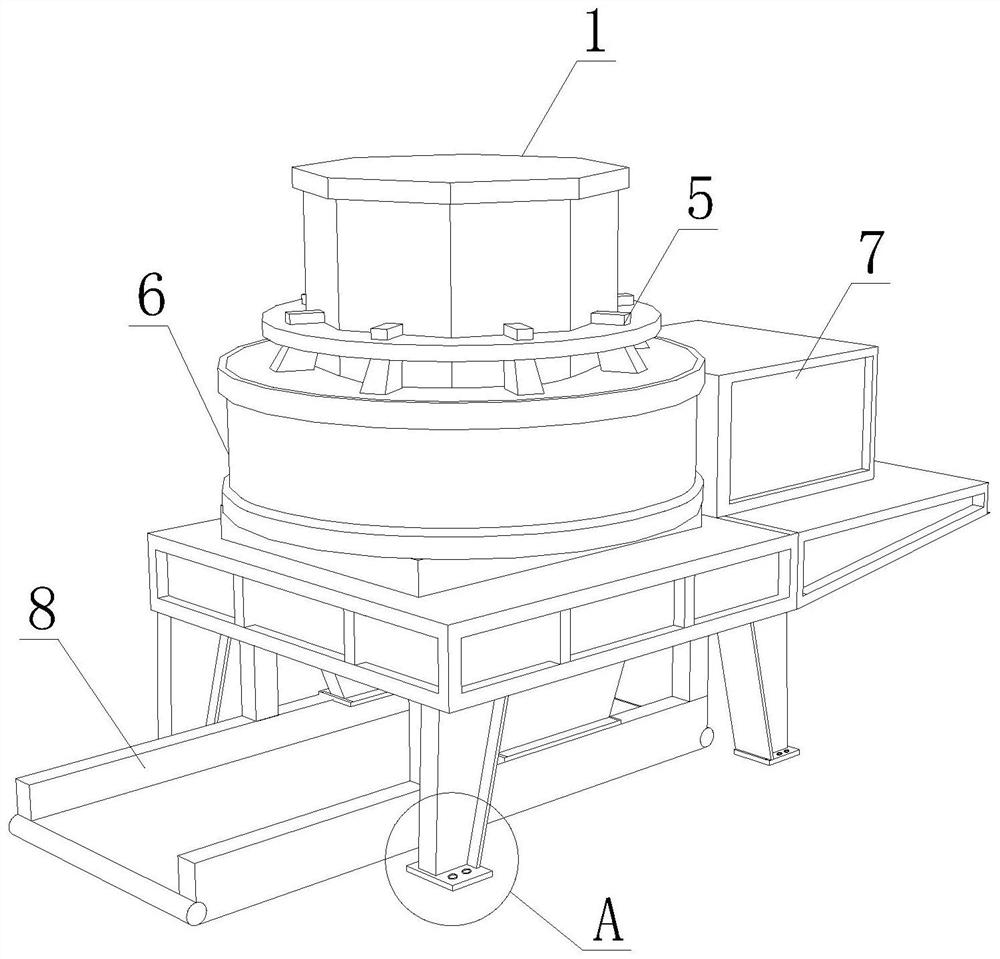

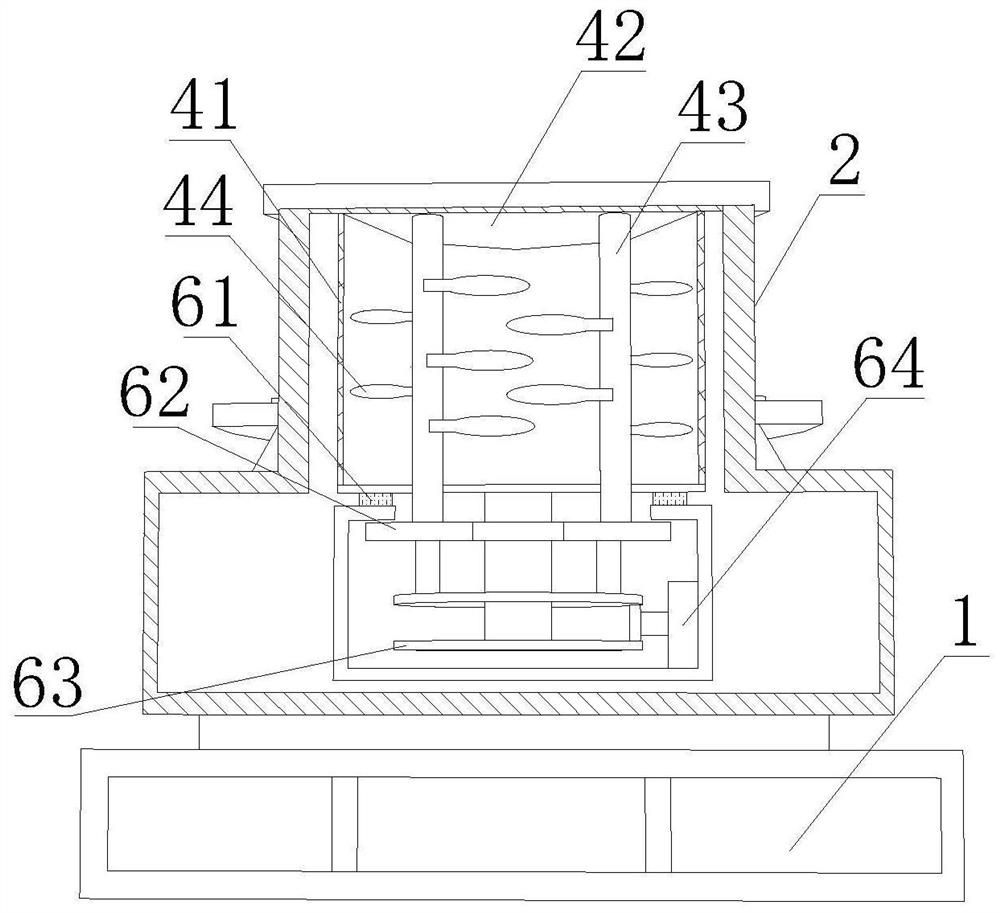

[0037] Such as Figure 1-5As shown, the present invention provides a centrifugal high-efficiency sand crushing device for ductile iron, comprising a sand crushing device body 1, a device shell 2, a dustproof bin cover 3, a centrifugal sand crushing chamber 4, a sand outlet filter screen 41 and a stable protection Ring 5, the top of the sand crushing device body 1 is provided with a dust-proof bin cover 3, through which the dust-proof bin cover 3 can effectively reduce the dust flying out during sand crushing, and the bottom of the dust-proof bin cover 3 is provided with a centrifugal sand-crushing chamber 4, The outer ring of the centrifugal sand chamber 4 is fixedly equipped with a sand outlet filter screen 41, and the outside of the centrifugal sand chamber 4 is fixedly installed with a device casing 2, and the outer ring of the device casing 2 is fixedly installed with a stabilizing protection ring 5, through which the stabilizing protection ring 5 The stability of the devi...

Embodiment 2

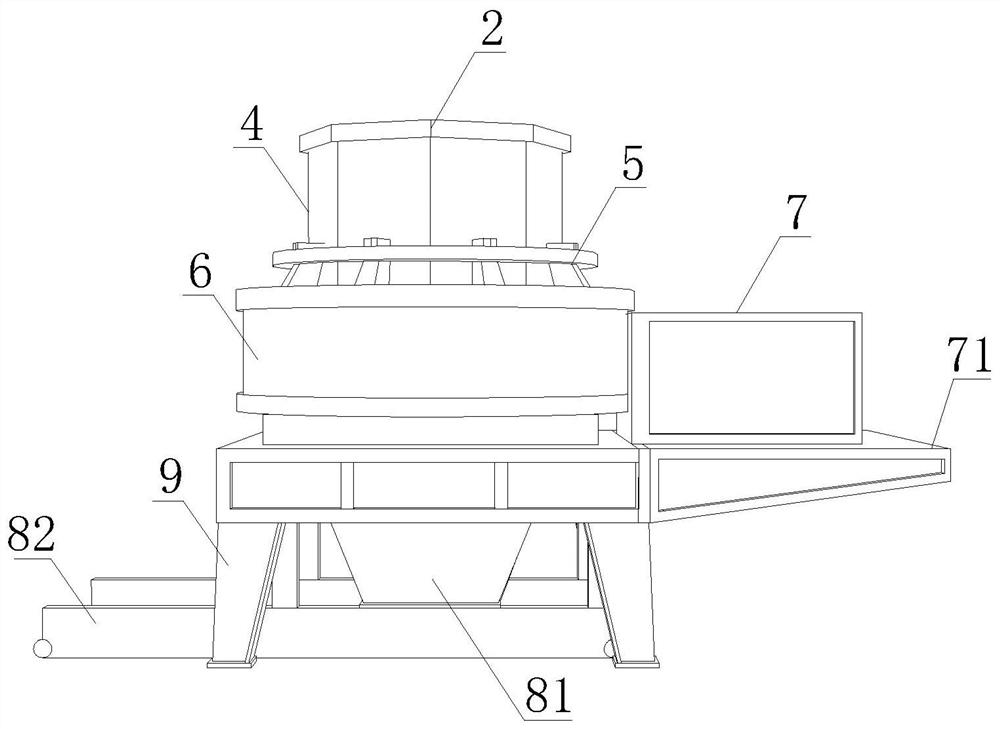

[0039] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a rotating gear is arranged below the stirring gear 62, a driving bevel gear is arranged under the right side of the rotating gear, and a driving bevel gear is arranged below the driving bevel gear. There is a centrifugal bevel gear 63, the middle part of the centrifugal bevel gear 63 is provided with a centrifugal rotating shaft, the top of the centrifugal rotating shaft extends to the bottom of the centrifugal sand chamber 4, and the right side of the driving bevel gear is fixedly connected with a power source 64, and the power source 64 is The centrifugal sand chamber 4 improves the power support, the right side of the drive control chamber 6 is fixedly connected with a muffler 7, the lower part of the muffler 7 is fixedly connected with a lifting plate 71, and the lower part of the drive control chamber 6 is fixedly connected with a discharge d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com