Hardware mold machining device

A mold processing and hardware technology, applied in the field of hardware processing, can solve the problems of slow work efficiency, overheating of stamping dies, hidden safety hazards, etc., and achieve the effect of improving production quality and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

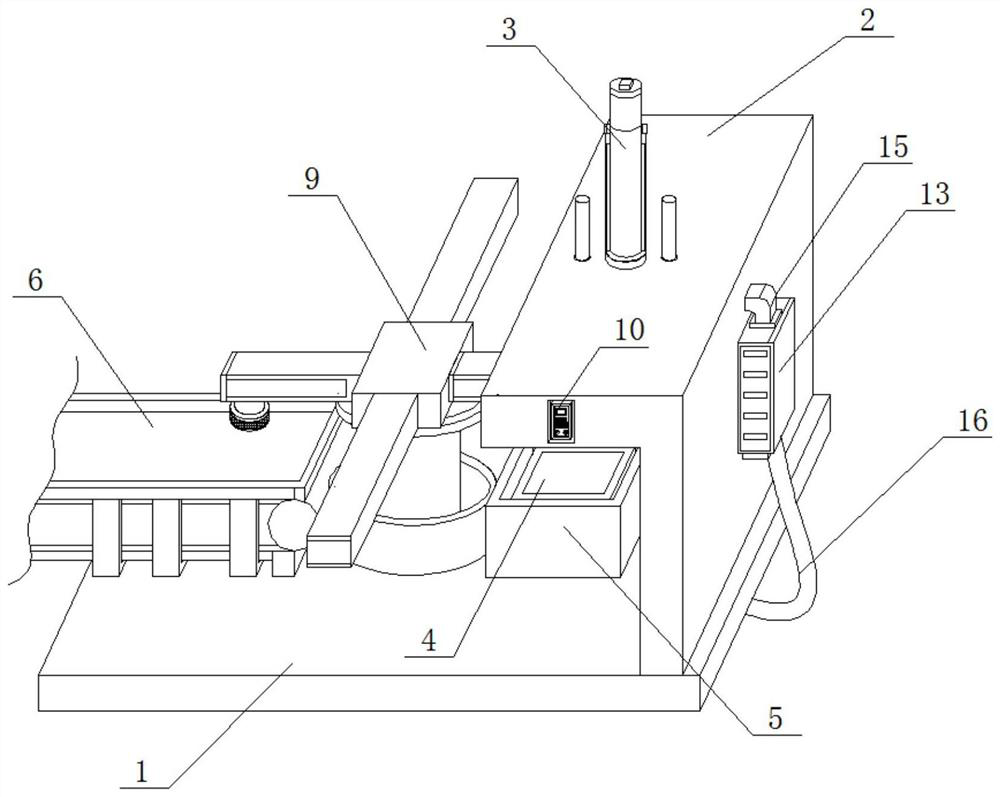

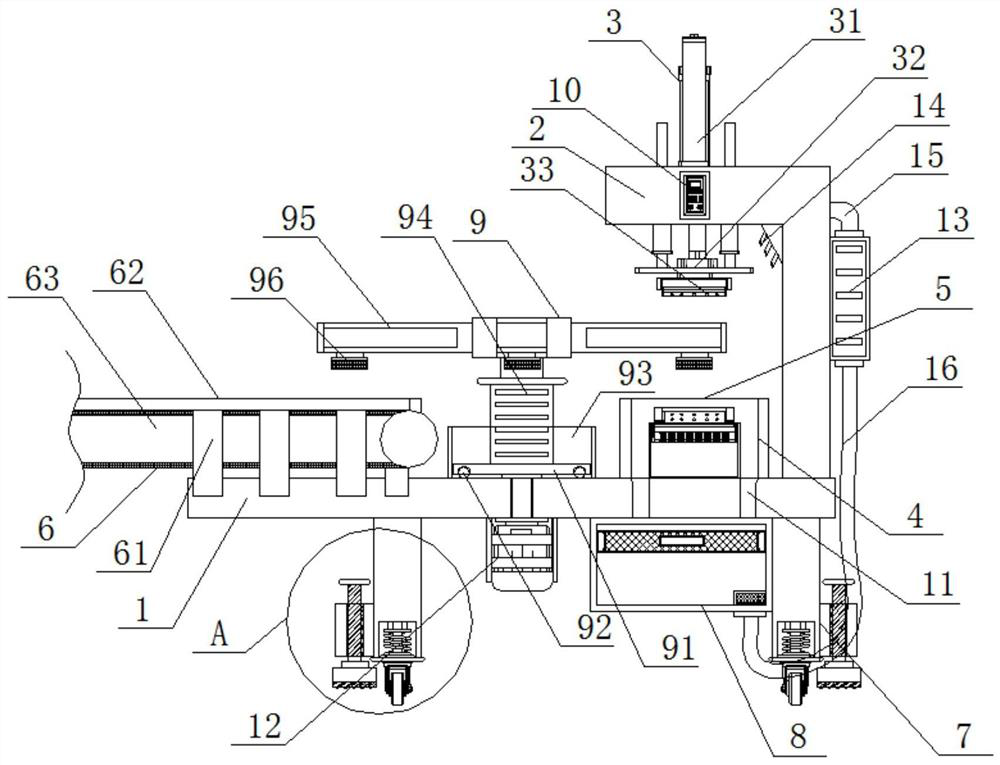

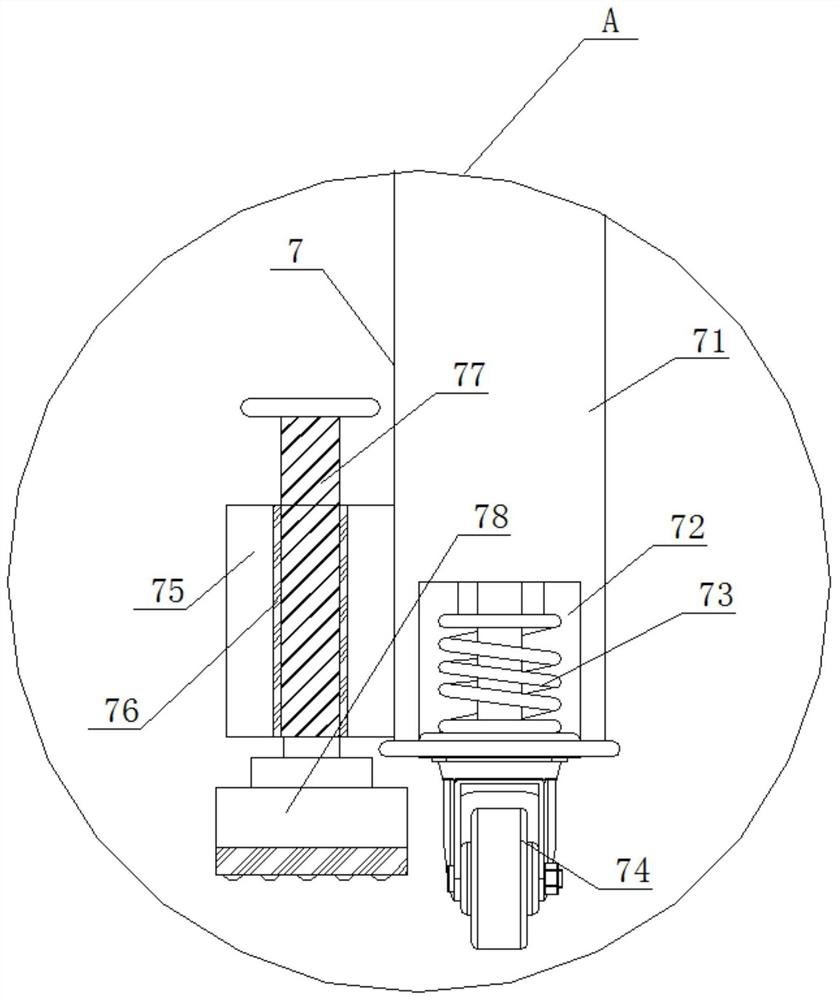

[0042] see Figure 1-6 , a mold processing device for hardware, including a workbench 1, a frame 2 is fixedly installed on the top right side of the workbench 1, an upper pressing assembly 3 is fixedly installed on the top of the frame 2, and the front side of the frame 2 A control switch 10 is fixedly installed on the top, and the section shape of the frame 2 is L-shaped. The lower pressing assembly 4 is fixedly installed, and the top of the workbench 1 on both sides of the outer frame 5 is provided with leaking grooves 11, and the bottom of the workbench 1 is arranged in a 2×2 matrix and fixedly installed with a support mechanism 7 , the right side of the bottom of the workbench 1 is fixedly installed with a water storage assembly 8, the bottom of the leaking tank 11 communicates with the top of the water storage assembly 8, and the middle of the bottom of the workbench 1 is fixedly installed with a drive motor 12, the drive motor 12 The output end runs through the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com