Box girder pouring equipment

A kind of equipment and box girder technology, applied in the field of box girder pouring equipment, can solve problems such as damage and waste, achieve the effect of reducing cost and waste, and speeding up the pouring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-8 The application is described in further detail.

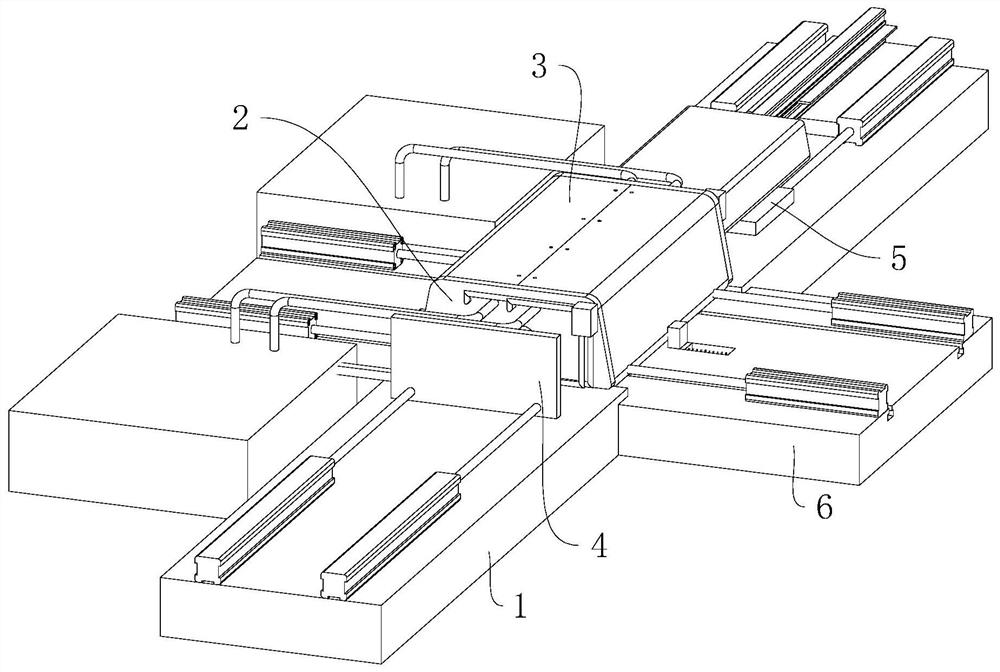

[0041] see figure 1 , a box girder pouring equipment, including machine base 1, pouring inner mold 2, pouring outer mold 3, and a mobile seat 4 and a forming slide 5 that are horizontally slidably arranged on the upper end of the machine base 1.

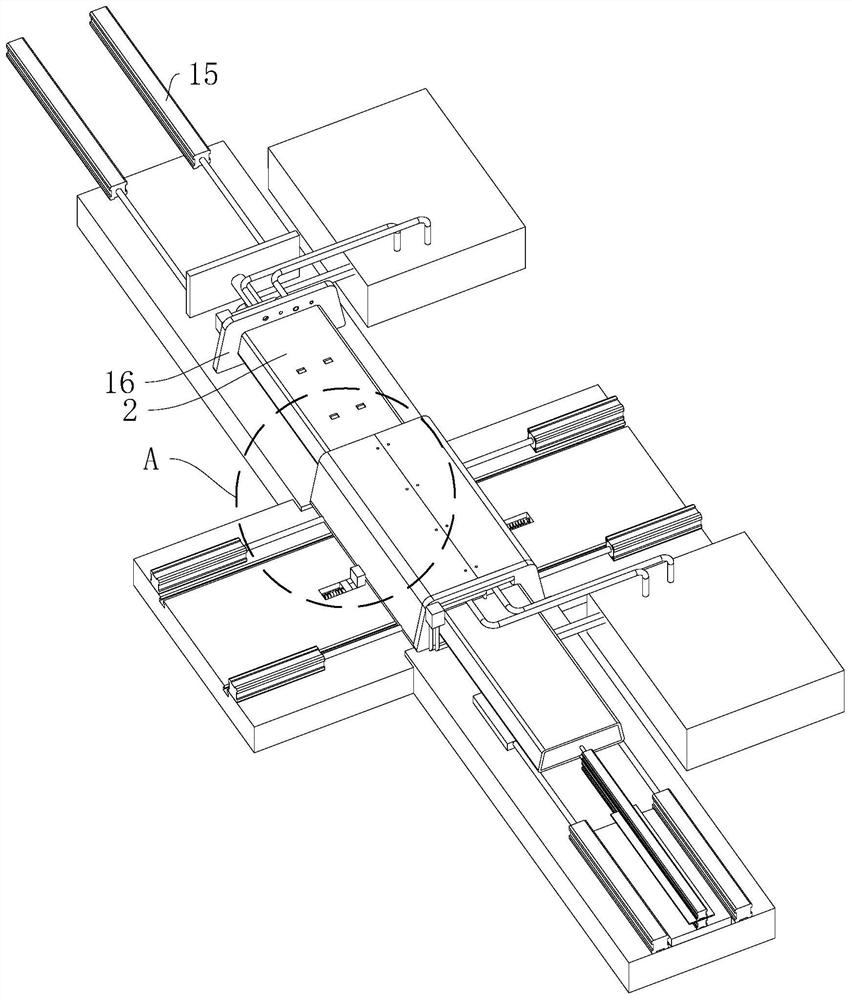

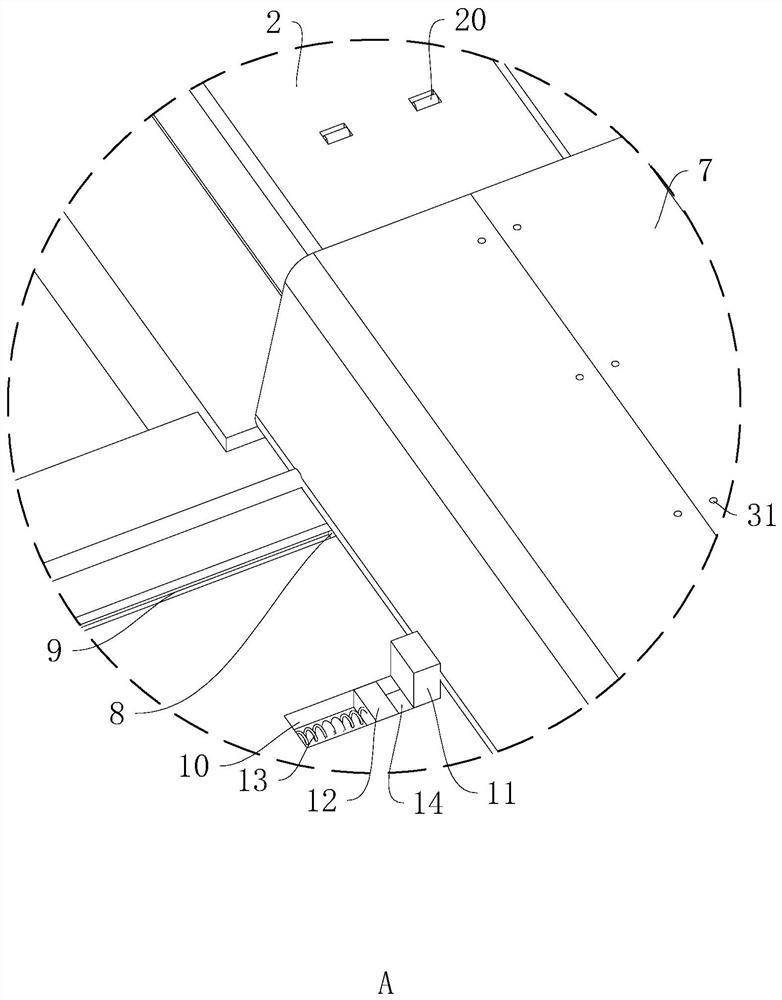

[0042] see figure 2 with image 3 The two sides of the middle part of the machine base 1 are integrally provided with supporting slides 6, the supporting slides 6 are perpendicular to the machine base 1, the two supporting slides 6 and the machine base 1 form a "ten" shape, and the pouring outer mold 3 includes two halves The mold casing 7, the structure and shape of the two half mold casings 7 are exactly the same, and at the same time, the central axis of the machine base 1 is symmetrical, the upper ends of the two half mold casings 7 are in contact, and the lower ends of the two half mold casings 7 are respectively provided with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com