A spring pin for electric power fittings that is convenient for robot maintenance work

A technology of electric fittings and spring pins, which is applied to springs, springs/shock absorbers, coil springs, etc., can solve problems such as high installation risk, inconvenient operation, and complex structure, so as to improve the reliability of pin connection, improve reliability, Reduce the effect of relative motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

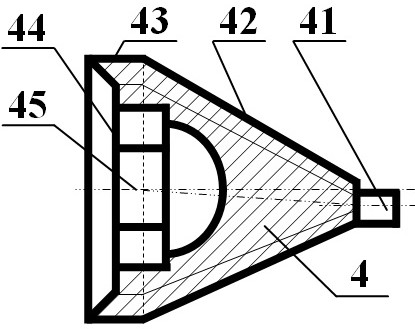

[0071] The technical solutions of the present invention are described in detail below in conjunction with the accompanying drawings and specific embodiments:

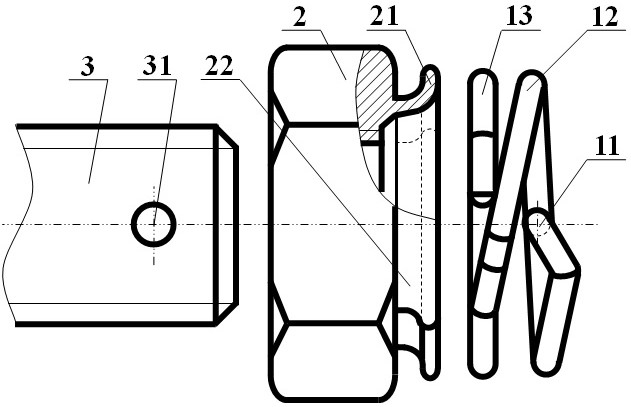

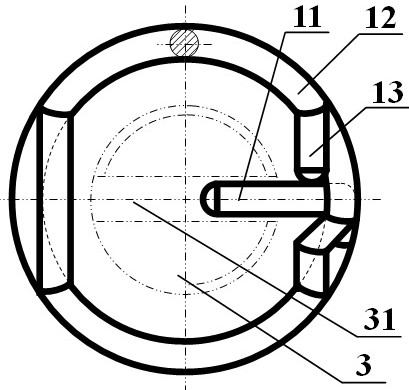

[0072] figure 1 It is a schematic diagram of the overall structure of the spring pin, the nut 2 and the bolt 3 . The bolt 3 includes a cylindrical screw and a head, with an external thread on the screw, and a radial pin hole 31 at the end of the screw away from the head; it is the existing loose connection for power fittings. bolts with pin holes. The present invention does not change the existing bolt structure with pin holes for loose connection of power fittings, so that the nut 2 with the spring pin of the present invention can be used for the replacement of missing nuts and closing pins of power fittings, which is convenient for eliminating defects and maintenance work.

[0073] The nut 2 has an axial through hole, and the inner surface of the through hole has an inner thread, and the inner thread cooperates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com