Transparent one-way light-emitting light source module

A technology of one-way light output and light source module, which is applied in the light guide, light guide, optics and other directions of the lighting system, which can solve the problems of high cost, complicated process, and reduced light transmittance, and achieve good collimation, high transparency, Effects with low production difficulty and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

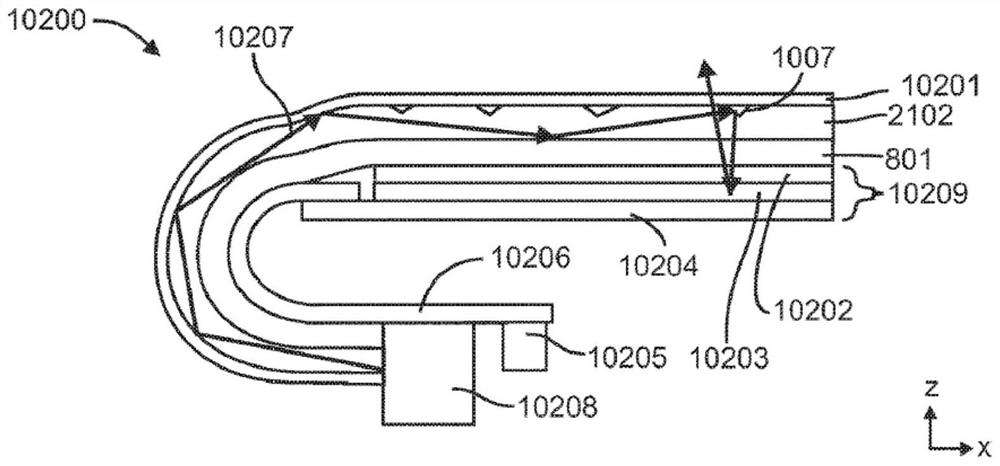

[0027] Embodiment one: if Figure 4 As shown, a transparent one-way light emitting light source module includes a light source 1 and a wedge-shaped light guide plate 2. The wedge angle is γ. The wedge-shaped light guide plate 2 includes a light incident surface 20, a first surface 21 and a second surface 22. The first surface 21 is provided with a bonding layer 3, and the material of the wedge-shaped light guide plate 2 is PC, PMMA or glass with a refractive index of 1.5 to 1.7, which is greater than the refractive index of the bonding layer 3 or more than 0.05. The material of the bonding layer 3 can choose a refractive index 1.5-1.3 PMMA, silica gel, acrylic resin or epoxy resin, etc., the light emitted by the light source 1 enters the wedge-shaped light guide plate 2, and when the light 201 reaches the first surface 21 at the junction of the wedge-shaped light guide plate 2 and the bonding layer 3, it is incident The angle is α, when α is greater than the total reflection a...

Embodiment 2

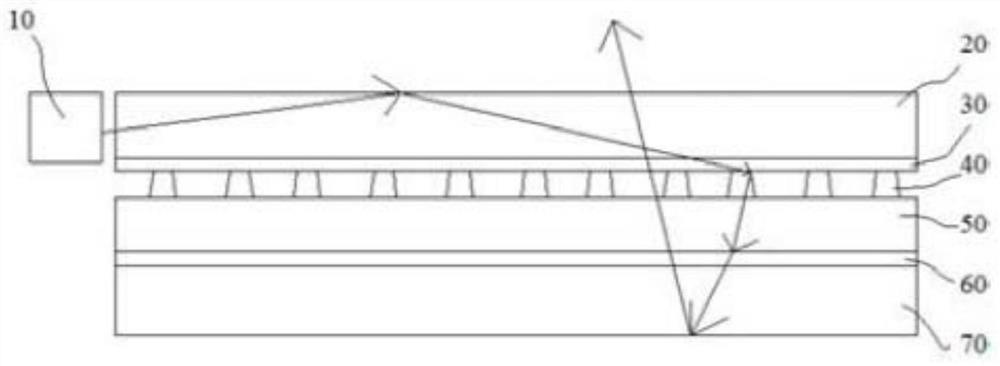

[0029] Embodiment two: if Image 6 As shown, on the basis of Embodiment 1, a protective layer 5 is provided on the side of the second surface 22 of the wedge-shaped light guide plate 2 facing away from the bonding layer 3, and the refractive index of the protective layer 5 is lower than that of the bonding layer, so For the light in the wedge-shaped light guide plate 2, the total reflection angle α of the bonding layer 3 on the first surface 21 is greater than the total reflection angle Ω of the protective layer 5 on the second surface 22, so the light 202 is on the second surface Total reflection will occur when it is on the surface 22, but total reflection may not occur when it is on the first surface 21. Since after each total reflection, the speed of light 202 approaching the total reflection angle is 2γ degrees, so the total reflection angle α only needs to be greater than the total reflection angle Ω by 2γ degrees, that is

[0030] α-Ω≥2γ

[0031] So the refractive ind...

Embodiment 3

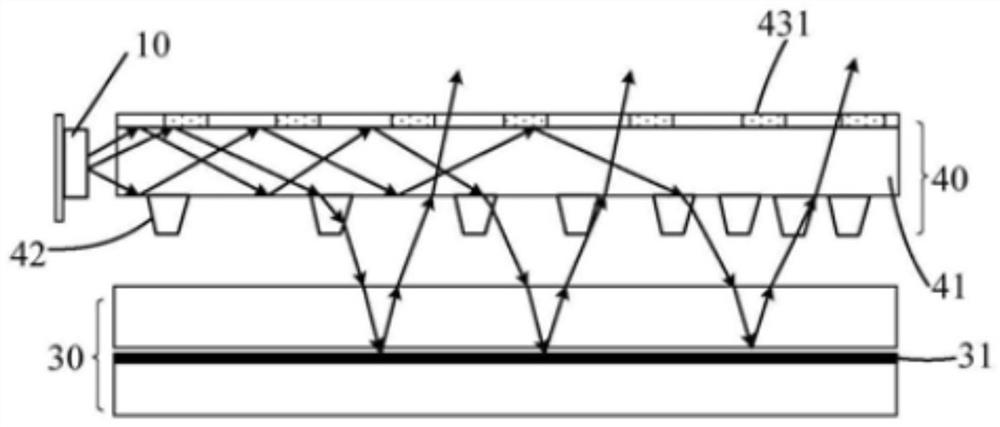

[0034] Embodiment three: as Figure 7 As shown, on the basis of Embodiment 1, a trumpet-shaped first auxiliary light guide plate 6 is integrally provided on the side of the wedge-shaped light guide plate 2 facing the light source 1, and the included angle of the horn mouth is θ, which includes two auxiliary surfaces 23 and 24. When the light irradiates on the auxiliary surfaces 23 and 24, the light will be effectively collimated. When the light 301 is irradiated on the auxiliary surface 23, total reflection occurs on the surface 23, and its travel angle is deflected by θ degrees in the counterclockwise direction. The light 302 When it is irradiated on the auxiliary surface 24, total reflection occurs on the surface 24, and its travel angle is deflected by θ degrees in the clockwise direction, so the light rays 301 and 302 are collimated after passing through the auxiliary surfaces 23 and 24, and then the light rays reach the first surface 21 , the incident angle α of the rays ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com