Non-contact indirect excitation dual-purpose generator

A generator, non-contact technology, applied in the direction of friction generator, generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, etc., can solve the restrictions on the popularization and application of self-powered sensor monitoring technology Avoid problems such as damage to the energy converter, wear and tear failure, and achieve the effects of high natural frequency and reliability, strong power generation capacity, and avoiding low-frequency resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

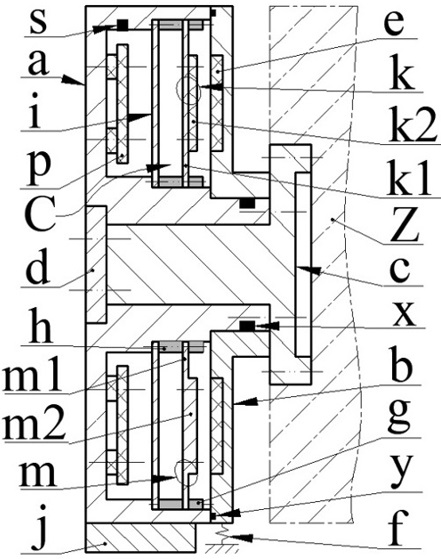

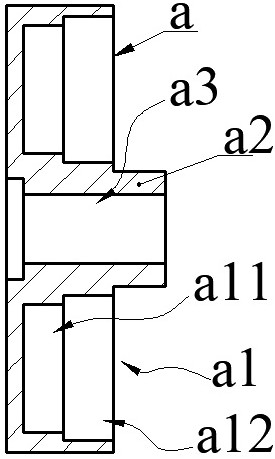

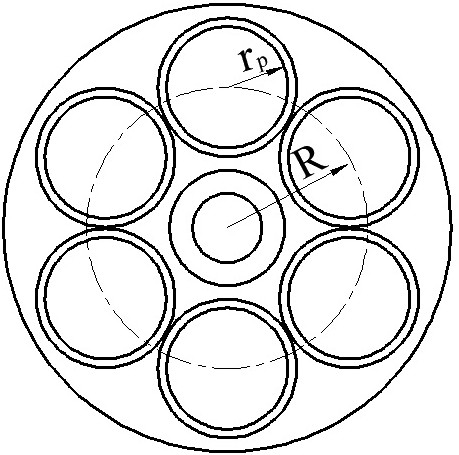

[0028] A dual-purpose generator with non-contact indirect excitation, which mainly consists of a casing a, an excitation disk b, a rotating shaft c, a stopper d, an excitation magnet e, a spring f or an inertia block j, a pressure ring g, a cavity ring h, and a transducer I, circuit board p, sensor s and coupler, the coupler is a magnetic coupler k or a non-magnetic coupler m; the rotating shaft c is installed on the rotating body Z, the casing a is set on the rotating shaft c, and the excitation disc b is set On the casing a, the excitation magnet e is installed on the excitation disk b, the sensor s, the circuit board p, the transducer i and the coupler are installed on the casing a, and the circuit board p is equipped with energy conversion and control circuits and transmitters. In the system, the transducer i and the sensor s are connected to the circuit board p through different wire groups; one of the housing a and the excitation disk b rotates with the rotating shaft c, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com