Transformer fire extinguishing device with opening operation

A technology for a fire extinguishing device and a transformer, applied in the field of electrical equipment and transformer fire extinguishing equipment, can solve problems such as hidden dangers, environmental pollution, easy fire spread, etc., and achieve the effect of reducing the supply of oxygen, reducing hidden dangers, and being beneficial to fire fighting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

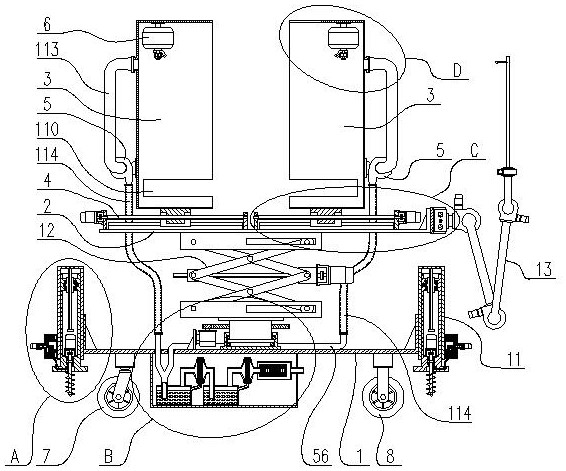

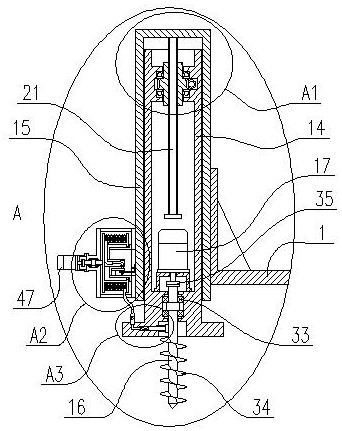

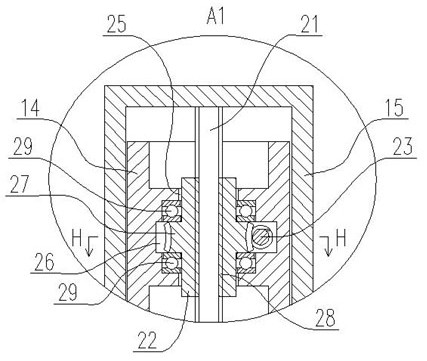

[0042] Depend on figure 1 As shown, the transformer fire extinguishing device with opening operation includes a vehicle frame 1, a platen 2, a pair of casings 3, a pair of lateral movement mechanisms 4, a pair of induced draft fans 5, and a pair of suspension type Dry powder fire extinguisher 6, universal wheel 7, walking wheel 8, smoke and dust purification mechanism 10, supporting grounding mechanism 11, scissor lifting mechanism 12 and opening mechanism 13, said universal wheel 7 and walking wheel 8 are installed on the frame 1 bottom, by Figure 2 to Figure 7 As shown, the supporting grounding mechanism 11 includes a leg 14, a square tube 15, a retracting and releasing mechanism, a ground rod 16, a second motor 17, a spring 18, a conductive voltage block 19 and a terminal 20, and the square tube 15 is fixedly installed On the vehicle frame 1, the supporting leg 14 is movably inserted in the square tube 15, and a telescopic mechanism is arranged between the square tube 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com