Preparation method and unfolding and recovering method of thin-wall cylindrical shell structure

A cylindrical shell structure and thin-walled technology, which is applied in the field of preparation of thin-walled cylindrical shell structures, can solve problems such as limited application, inability to realize automatic retraction, and inability to recycle, etc., to achieve the effect of reversible change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] DETAILED DESCRIPTION OF THE INVENTION The present embodiment is described in the preparation method of a thin-walled column shell structure, which is specifically:

[0019] Step 1: As the reinforcing material in a 1-3 layer, the shape memory polymer is formed as a resin matrix, and the shape memory composite material is prepared. The resin content of the composite is 65 to 85%, mainly in order to ensure the shape memory performance of the composite material. The fiber cloth that specifically selects 1 to 3 layers requires determination according to the type of different cloth, if it is too thick, it is not easy to fold, may no longer have a thin wall cylinder characteristic, if it is too thin, the mechanical properties are poor.

[0020] Step 2: Preparation of a sheet-like shape memory composite according to a particular size, after 0.5-6 hours of 60-120 ° C, initially, form a curl shape, then solidify, then curing, then curing at 120-200 ° C After heating 4-10h, complete, ...

specific Embodiment approach 2

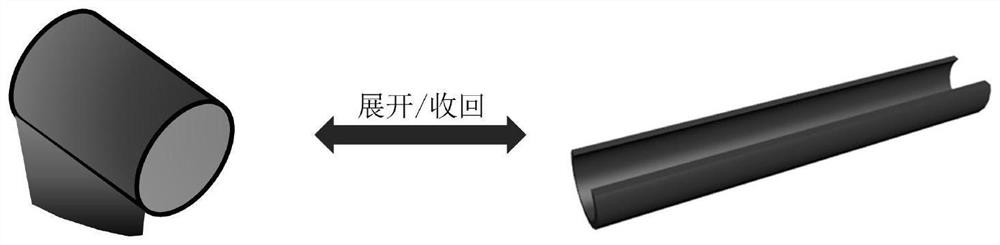

[0029] DETAILED DESCRIPTION OF THE INVENTION 2: An unfolded recovery method of the thin-walled shell structure prepared, and the method is specifically: when the room temperature is present, the prepared thin-walled column shell can be elastically unfained under triggering force, to obtain the state of the arm, and complete the task Through the corresponding external (heat, electricity, light, etc.), trigger the shape memory performance, with the interim shape of the thin-walled column shell structure, and complete the entire deformation process under the shape memory effect, the interim shape of the thin-walled column shell structure.

Embodiment 1

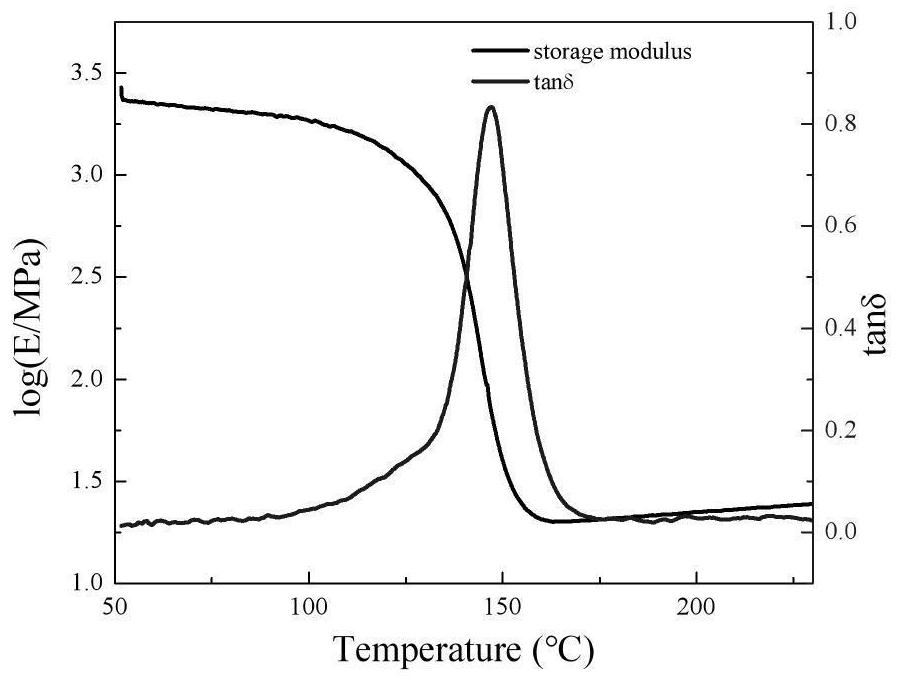

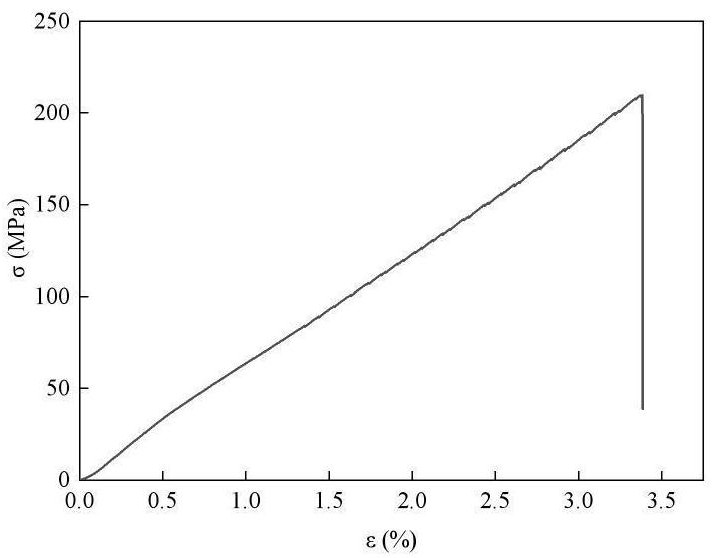

[0031] The use of isophorone diamine, D230 is used as the curing agent, and the epoxy resin E51 is a resin matrix, the carbon fiber cloth is used as the reinforcing material, and the shape memory epoxy resin composite material is prepared, and the obtained matrix material is subjected to dynamic heat mechanical analysis (DMA), like figure 2 As shown, the T of the resulting material g It was 147.2 ° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com