Preparation method and application of efficient halogen-free flame retardant for polypropylene

A technology of polypropylene and flame retardants, which is applied in the field of flame retardants and can solve problems such as the flammability of aluminum hypophosphite flame retardants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

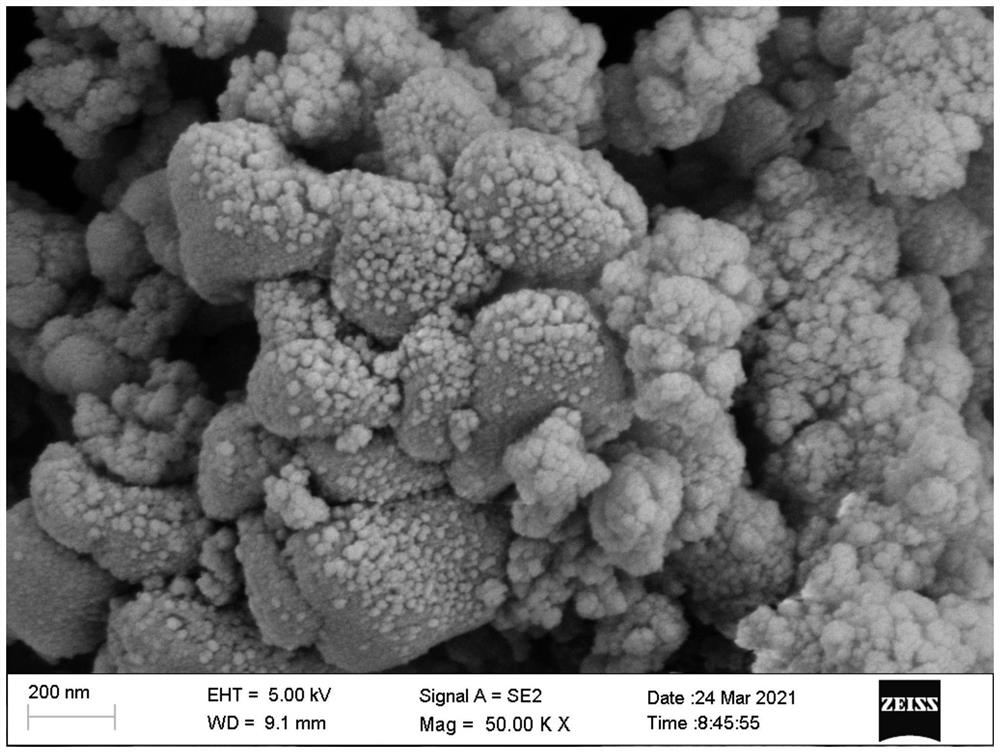

Image

Examples

Embodiment 1

[0024] (1) Add 135 parts of sodium hypophosphite and 146 parts of aluminum sulfate into the reaction vessel that has been added with water, turn on heating and stirring to raise the temperature to 105°C, keep the constant temperature until completely dissolved; then slowly add the sodium hypophosphite solution Stir and react in the aluminum sulfate solution at 105°C for 6 hours to obtain aluminum hypophosphite slurry;

[0025] (2) Turn off the heating and lower the temperature. When the aluminum hypophosphite slurry cools down to 70°C, add the magnesium hydroxide aqueous dispersion system (add 8 parts of magnesium hydroxide to the water to stir and disperse), and at a constant temperature of 70°C, the magnesium hydroxide and hypophosphorous acid The aluminum slurry is neutralized, and after 4 hours of reaction, it is suction filtered and washed to obtain an aluminum hypophosphite product coated with magnesium hypophosphite and aluminum-magnesium hypophosphite;

[0026] (3) 8 p...

Embodiment 2

[0028] (1) Add 142 parts of sodium hypophosphite and 154 parts of aluminum sulfate into the reaction vessel that has been added with water, turn on heating and stirring to raise the temperature to 115°C, keep the constant temperature until it is completely dissolved; then slowly add the sodium hypophosphite solution Stir and react in the aluminum sulfate solution at 110°C for 4 hours to obtain an aluminum hypophosphite slurry;

[0029] (2) Turn off the heating and lower the temperature. When the aluminum hypophosphite slurry cools down to 80°C, add the magnesium hydroxide water dispersion system (add 9.5 parts of magnesium hydroxide to the water to stir and disperse). The aluminum slurry is neutralized, and after 3 hours of reaction, it is filtered and washed to obtain an aluminum hypophosphite product coated with magnesium hypophosphite and aluminum-magnesium hypophosphite;

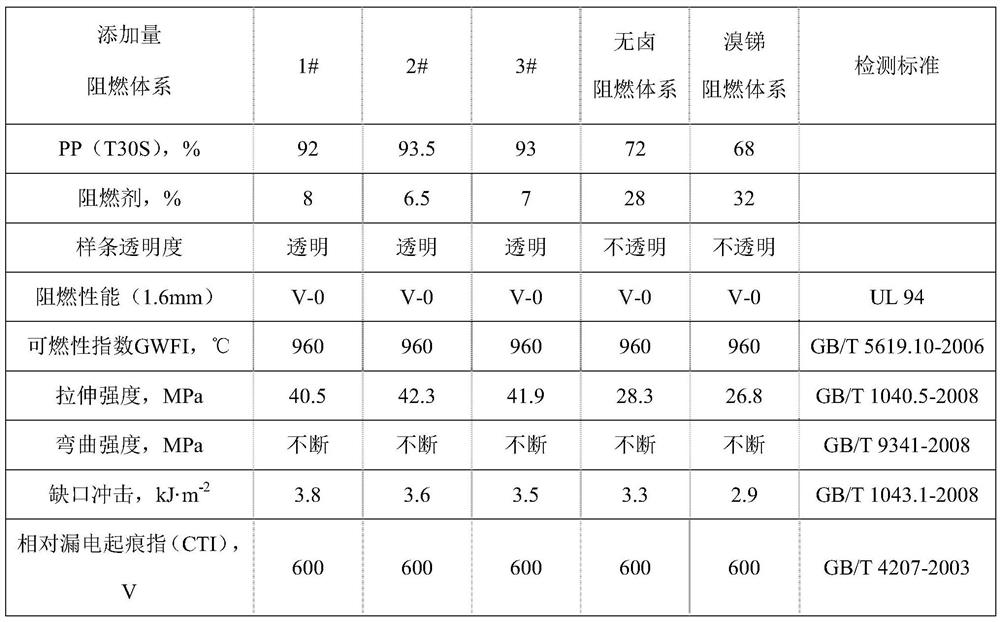

[0030] (3) 6.5 parts of coated products of gained, 93.5 parts of polypropylene, 0.02 part of synergis...

Embodiment 3

[0032] (1) Add 126 parts of sodium hypophosphite and 138 parts of aluminum sulfate into the reaction vessel that has been added with water, start heating and stirring to raise the temperature to 95°C, keep the constant temperature until completely dissolved; then slowly add the sodium hypophosphite solution Stir and react in the aluminum sulfate solution at 95°C for 5 hours to obtain an aluminum hypophosphite slurry;

[0033] (2) Turn off the heating and lower the temperature. When the aluminum hypophosphite slurry cools down to 70°C, add the magnesium hydroxide water dispersion system (add 6 parts of magnesium hydroxide to the water and stir to disperse). The aluminum slurry is neutralized, reacted for 2.5 hours, and then filtered and washed to obtain an aluminum hypophosphite product coated with magnesium hypophosphite and aluminum-magnesium hypophosphite;

[0034] (3) 7 parts of coated products of gained, 93 parts of polypropylene, 0.04 part of synergist compound (mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com