Flame-retardant waterborne polyurethane adhesive and preparation method thereof

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive additives, etc., can solve problems such as fire hazards, reduce odor, reduce VOC emissions, and solve flammable or flammable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

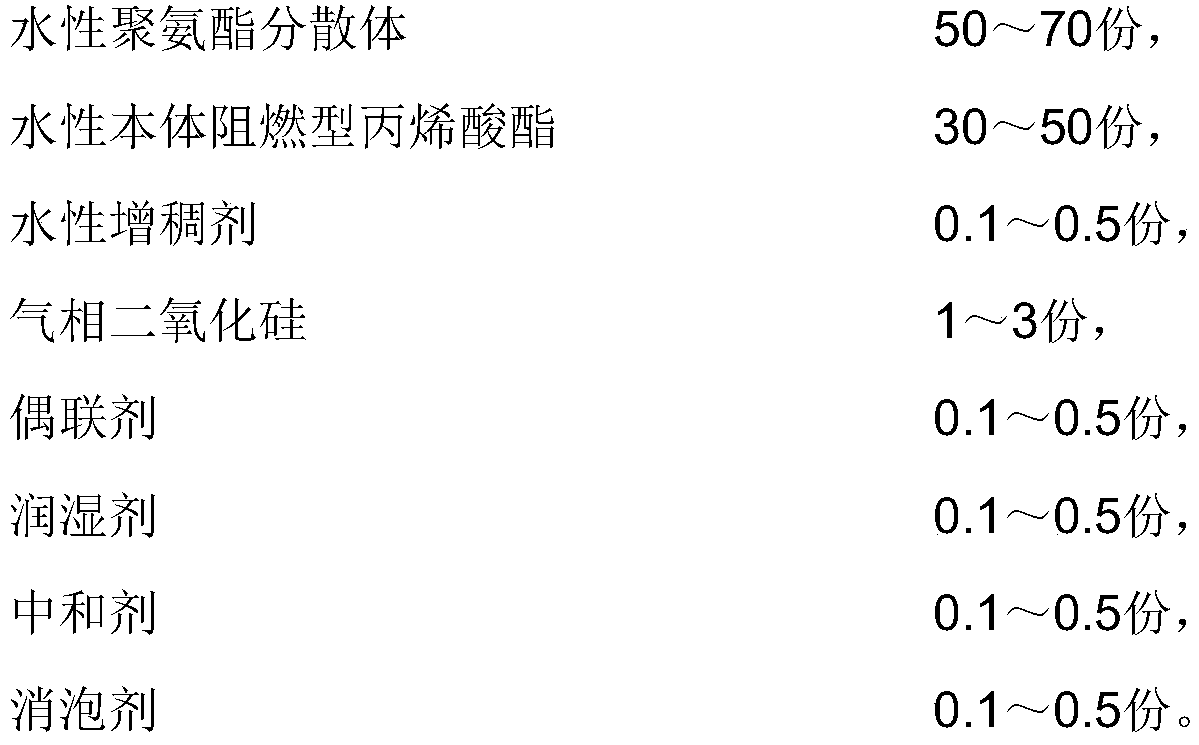

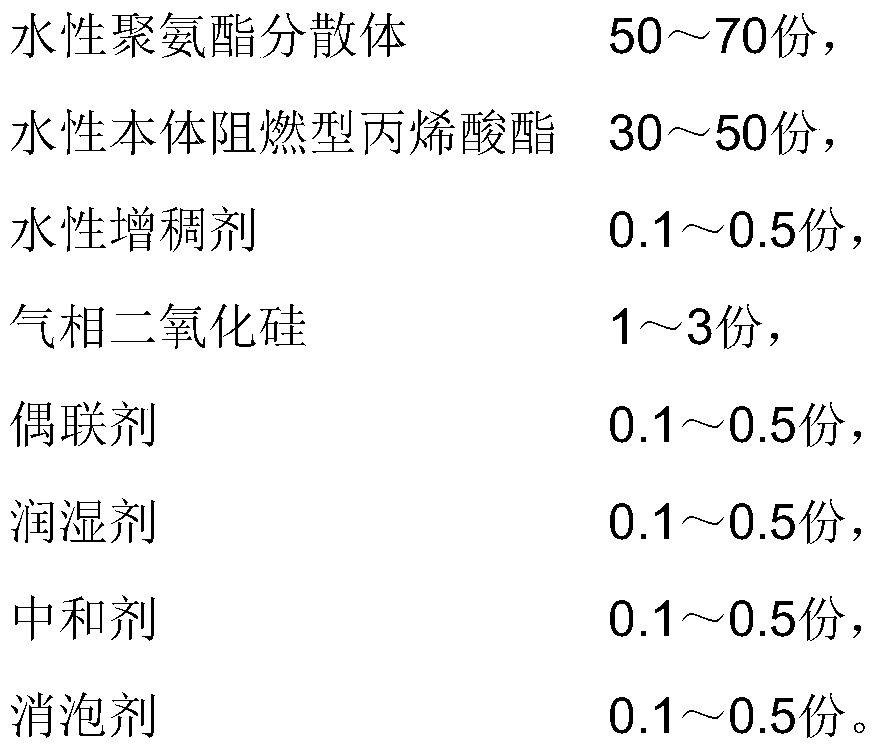

Embodiment approach

[0016] (1) The water-based polyurethane dispersion can adopt one or more of U53 of Bayer in the prior art, U54 of Bayer, U56 of Bayer, 1633 of Wanhua Chemical, 1665 of Wanhua Chemical, and 1637 of Wanhua Chemical kind.

[0017] (2) The water-based bulk flame-retardant acrylate can be the water-based bulk flame-retardant acrylate in Chinese patent CN102408853B (applicant: Beijing Gaomeng New Materials Co., Ltd.).

[0018] (3) The water-based thickener can adopt TEGO Visco Plus 3000 of Evonik in the prior art, Acrysol RM2020 of Rohm and Haas, Acrysol RM8W of Rohm and Haas, Acrysol RM12W of Rohm and Haas, Rohm and Haas One or more of Acrysol RM5000 from Sri Lanka, HEUR-A from Hefei Anke, HEUR-B from Hefei Anke, and Vesmody A801 from Wanhua Chemical.

[0019] (4) The coupling agent can be one or more of KH450, KH550, KH560, KH570, KH602 in the prior art.

[0020] (5) The wetting agent may be one or more of Evonik's TEGO WET KL245, BYK's BYK345, BYK's BYK346, BYK's BYK349, and ...

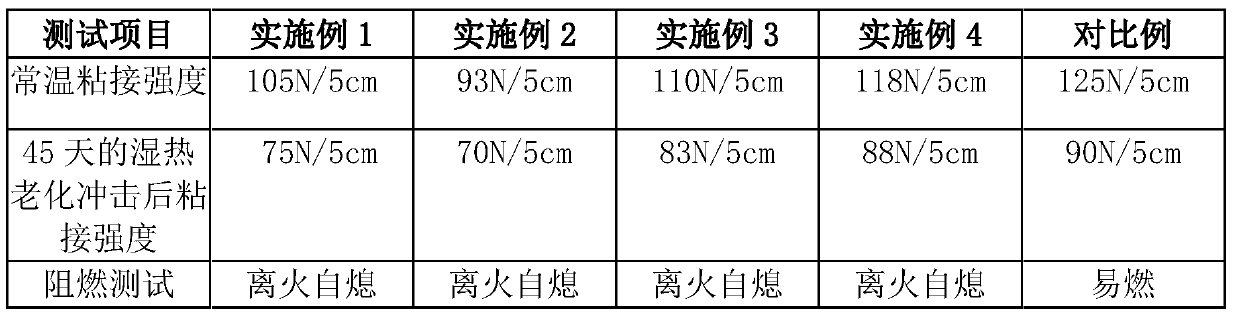

Embodiment 1

[0031] A flame-retardant water-based polyurethane adhesive, the preparation method of which can include (by weight): 20 parts of Bayer's U54, 45 parts of Bayer's U56, 35 parts of water-based bulk flame-retardant acrylate, 1 part of gas-phase dioxide Silicon, 0.2 part of coupling agent KH550, 0.15 part of Evonik's TEGO WET KL245, 0.2 part of AMP-95, 0.1 part of BASF Foamaster 8034 were mixed, and stirred at 500-600r / min for 10-20min, and then mixed with 0.15 part of pure Dilute 0.15 parts of Evonik’s TEGO ViscoPlus 3000 with water and slowly add it dropwise to the mixture. After the addition, continue to stir at 700-800r / min for 30-60min. Take a sample to test the viscosity. When the viscosity is in the range of 3000-7000mPa.s The stirring can be stopped, and the main glue can be obtained by filtering with a 200-mesh filter screen. The main glue and the water-based isocyanate curing agent Bayer's Desmodur DN are used in a weight ratio of 100:5 to obtain a flame-retardant water-...

Embodiment 2

[0034] A flame-retardant water-based polyurethane adhesive, the preparation method of which can include (by weight): 25 parts of Bayer's U54, 45 parts of Bayer's U56, 30 parts of water-based bulk flame-retardant acrylate, 1.5 parts of gas-phase dioxide Silicon, 0.25 parts of coupling agent KH560, 0.2 parts of BYK's BYK345, 0.15 parts of N-methylethanolamine, 0.2 parts of BYK's BYK018 are mixed, and stirred at a speed of 500-600r / min for 10-20min, and then 0.2 parts Dilute 0.2 parts of Rohm and Haas Acrysol RM2020 with pure water and slowly add it dropwise to the mixture. After the addition, continue to stir at 700-800r / min for 30-60min, take a sample to test the viscosity, when the viscosity is 3000-7000mPa.s Within the range, the stirring can be stopped, and the main glue can be obtained by filtering with a 200-mesh filter. The main glue is used in combination with the water-based isocyanate curing agent Bayer's Desmodur DN at a weight ratio of 100:3 to obtain a flame-retarda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com