A Treatment Method for Improving the Wear and Corrosion Resistance of Al-mg-Si Alloy

An al-mg-si, corrosion-resistant technology, applied in the treatment field of improving the wear and corrosion resistance of Al-Mg-Si alloys, can solve the problems of strong intergranular corrosion tendency, regional segregation, dendrite segregation, etc. Improve the structure, improve the wear and corrosion resistance, reduce the effect of dendrite segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Using common Al-Mg-Si alloy as material to prepare Al-Mg-Si alloy melt;

[0060] Wherein, the mass ratio of each component in the alloy melt is: Si: 3%, Mg: 4.5%, Al: 92.5%.

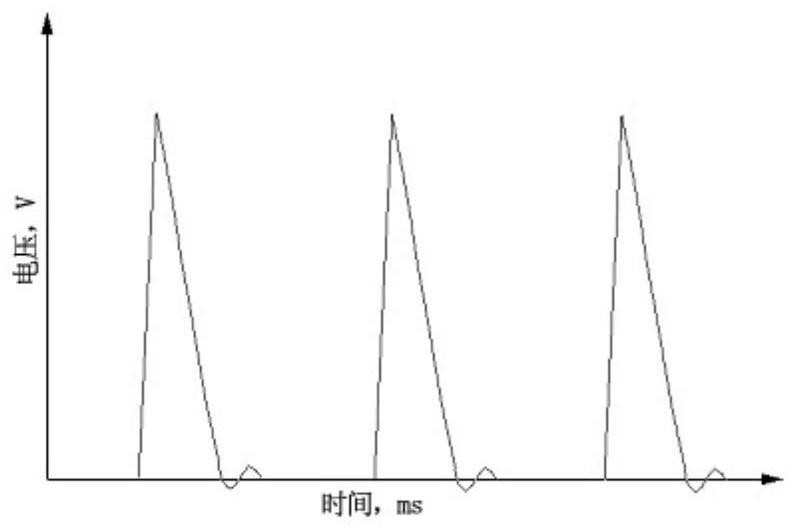

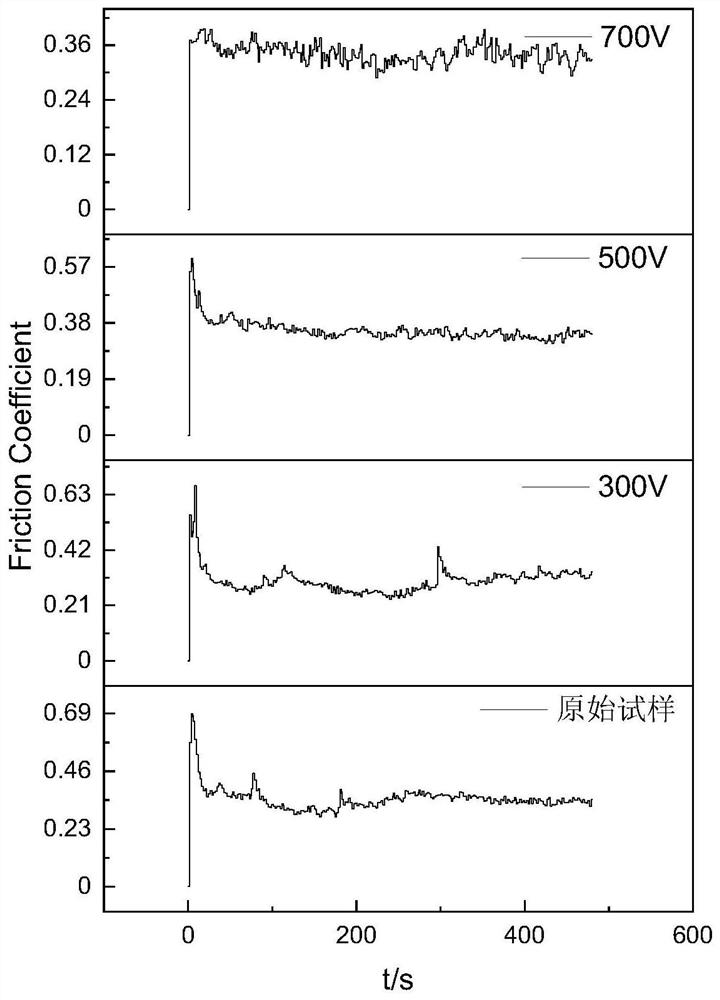

[0061] When the temperature of the Al-Mg-Si alloy melt is 720°C, an electric pulse device is used to perform electric pulse treatment on the Al-Mg-Si alloy melt to obtain an inoculated Al-Mg-Si alloy melt;

[0062] In the electric pulse processing process, the setting pulse voltage is 300V, and the pulse frequency is 3Hz; the output function of controlling the electric pulse device is: f(t)=Ae -αt ; Where, A is the amplitude; α is the rate of discharge; t is the time of action.

[0063] The inoculated Al-Mg-Si alloy melt is casted to obtain the treated Al-Mg-Si alloy.

Embodiment 2

[0065] Using common Al-Mg-Si alloy as material to prepare Al-Mg-Si alloy melt;

[0066] Wherein, the mass ratio of each component in the alloy melt is: Si: 3%, Mg: 4.5%, Al: 92.5%.

[0067] When the temperature of the Al-Mg-Si alloy melt is 720°C, an electric pulse device is used to perform electric pulse treatment on the Al-Mg-Si alloy melt to obtain an inoculated Al-Mg-Si alloy melt;

[0068] In the electric pulse processing process, the pulse voltage is set to 500V, and the pulse frequency is 3Hz; the output function of controlling the electric pulse device is: f(t)=Ae -αt ; Where, A is the amplitude; α is the rate of discharge; t is the time of action.

[0069] The inoculated Al-Mg-Si alloy melt is casted to obtain the treated Al-Mg-Si alloy.

Embodiment 3

[0071] Using common Al-Mg-Si alloy as material to prepare Al-Mg-Si alloy melt;

[0072] Wherein, the mass ratio of each component in the alloy melt is: Si: 3%, Mg: 4.5%, Al: 92.5%.

[0073] When the temperature of the Al-Mg-Si alloy melt is 720°C, an electric pulse device is used to perform electric pulse treatment on the Al-Mg-Si alloy melt to obtain an inoculated Al-Mg-Si alloy melt;

[0074] In the electric pulse processing process, the setting pulse voltage is 700V, and the pulse frequency is 3Hz; the output function of controlling the electric pulse device is: f(t)=Ae -αt ; Where, A is the amplitude; α is the rate of discharge; t is the time of action.

[0075] The inoculated Al-Mg-Si alloy melt is casted to obtain the treated Al-Mg-Si alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com