Vertical radial grouting settlement control method for rigid sleeve valve pipe bundles

A sleeve valve tube and rigid technology, which is applied in the field of grouting reinforcement and settlement control, can solve the problems of uncontrollable formation settlement deformation, inability to control settlement after the event, and unrealization, so as to avoid construction safety risks and shutdown processing risks, and quickly control Effects of settlement and prevention of settlement deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

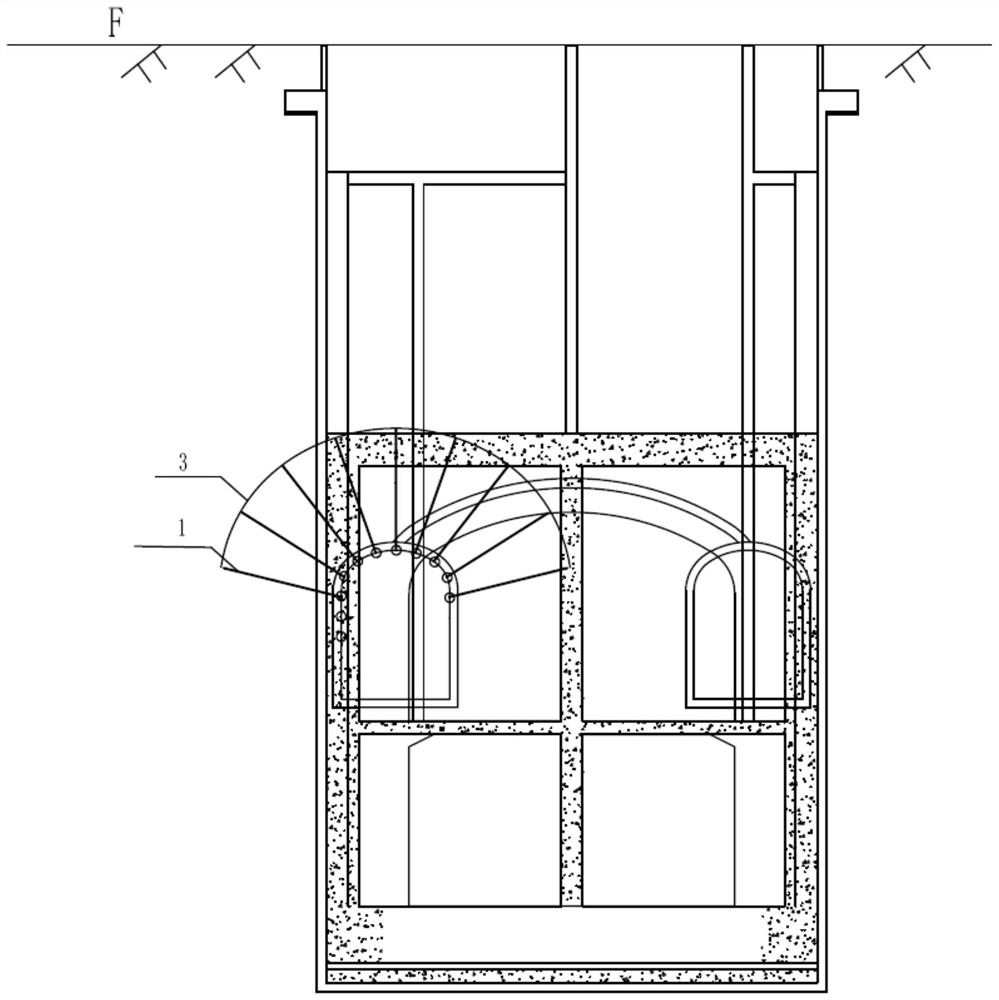

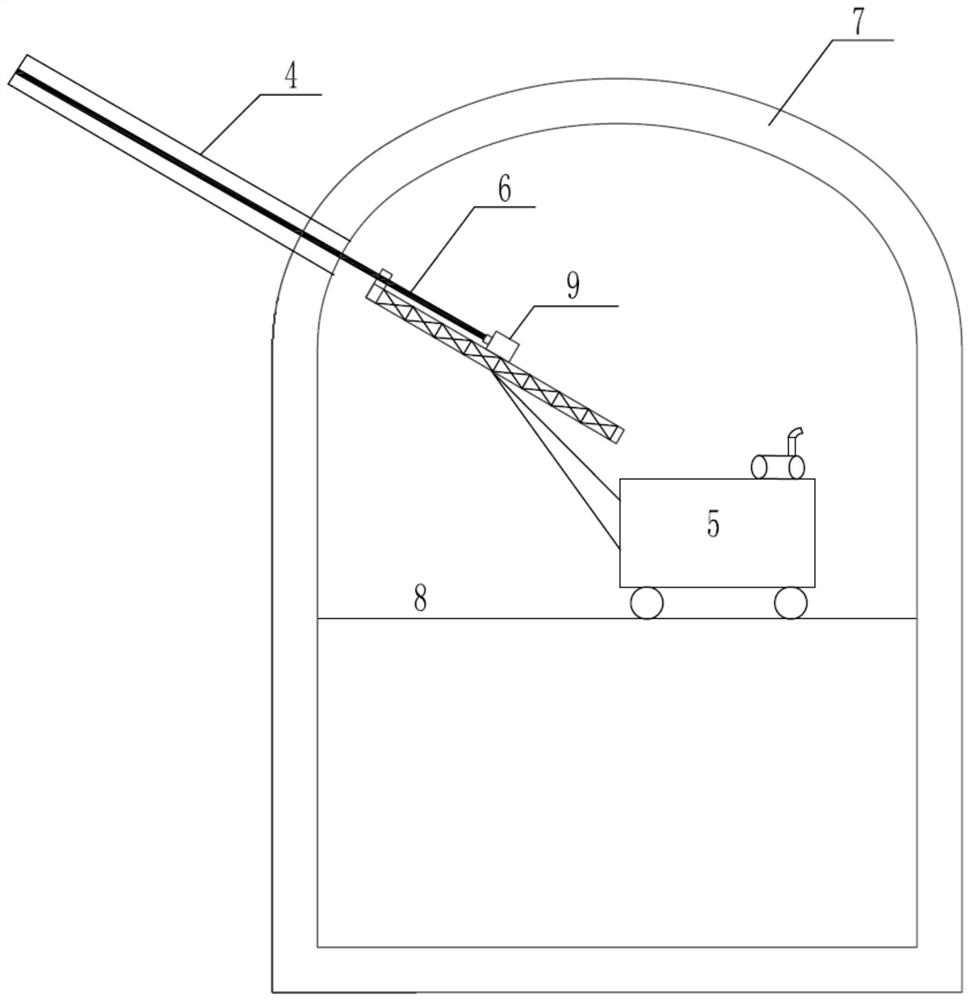

[0035] Next, the vertical radial rigid sleeve valve tube bundle grouting control settlement method of the present invention will be described in detail with reference to the accompanying drawings.

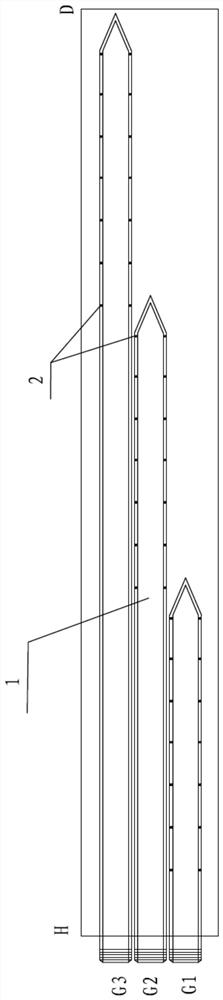

[0036] First, if figure 1 As shown, in step 1, the rigid sleeve valve tube bundle 1 is fabricated. First, determine the length of the steel pipe according to the distance from the hole H to the bottom of the hole D, and cut three steel pipes G1, G2, and G3 in order from short to long, and control the length difference to 3 meters. Drill overflow holes 2 on the steel pipes G1, G2 and G3, and then paste the patch on the overflow holes 2 and install the slurry valve sleeve. The front end of each steel pipe is processed into a pointed shape, and the other end, the grouting end, is processed into a wire Buckle connection, the processed steel pipes G1, G2 and G3 are firmly connected by welding or binding to form a rigid sleeve valve tube bundle 1.

[0037] In this step, as another non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com