Quick connection and separation device and method for connecting cylinder with steel casing

A separation device and steel casing technology, which is applied to drilling equipment and methods, earthwork drilling, drilling pipes, etc., can solve the problems of unfavorable construction period, high risk, and many construction procedures, so as to eliminate construction safety risks , The completion time of the process is short, and the effect of reducing construction personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

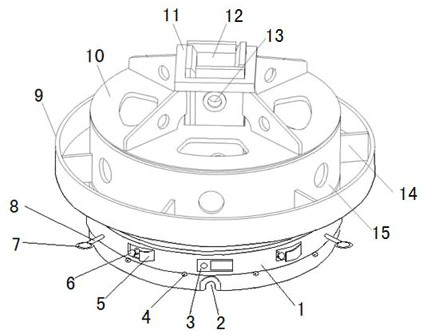

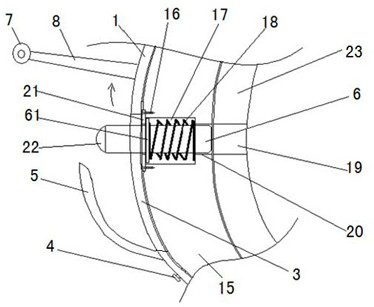

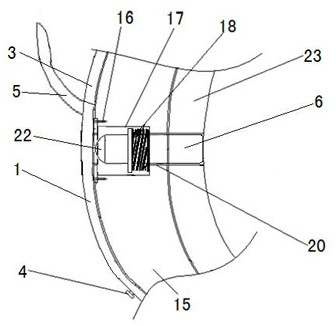

[0035] Example 1: as Figure 1 to Figure 5 As shown in the figure, a quick-connecting and separating device for connecting a flower tube and a steel protective tube includes a cylinder body 15, a protective ring 9, a top plate 10, a U-shaped groove 2, a connecting square tube 11 and a pin through hole 20, which is connected inside the square tube 11. It is the square hole 12 that is butted with the lower end of the drill pipe 25. After the butt joint, the two pass through the through hole 13 through which the two pass through the fixed post to complete the butt joint or vice versa. The protective ring 9 is located on the outer wall of the cylinder at the upper end of the pin rod through holes through the evenly distributed connecting plates 14, and is used to prevent collision and protect each pin rod through hole and its inner device. On the outer wall of the lower part of the cylinder of the connecting flower tube, there is a quick connection and separation device for each pin...

Embodiment 2

[0051] Example 2: as Figure 5 As shown, the difference from Embodiment 1 is that there is no switch lever on the outer wall of the switch rotary disk, and the pulling device of the switch rotary disk is: the upper part of the outer wall of the switch rotary disk 1 is fixed with an annular rack 31 by welding, and the upper end of the ring rack is There is a motor 30 on the cylindrical body 15 of the motor, the motor can be selected as a stepper motor, and a driving gear 29 is arranged on the motor shaft, and the driving gear meshes with the ring rack. When in use, the motor is connected to the power supply to control the opening and closing of the motor, and the ring gear is driven by the driving gear to drive the switch rotary disk 1 to rotate clockwise to complete the connection or separation of the connecting flower tube and the steel protective tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com