Inorganic insulation board blank drying equipment

A technology of inorganic thermal insulation and drying equipment, applied in progressive dryers, drying solid materials, drying gas layout, etc., can solve the problems of inability to synchronize double-sided drying of thermal insulation boards, cost-intensive, slow drying speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

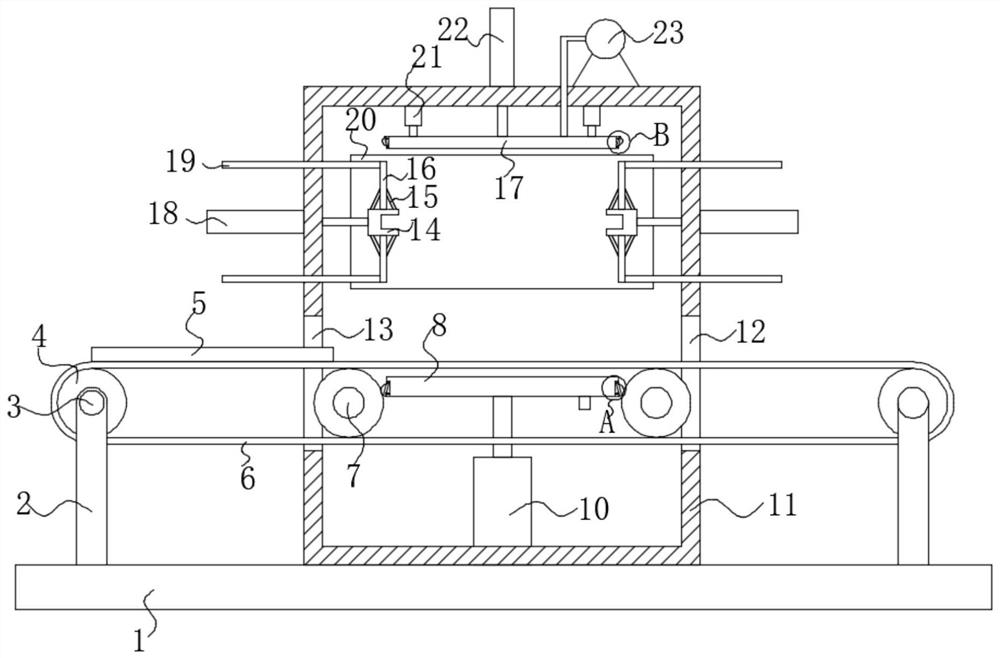

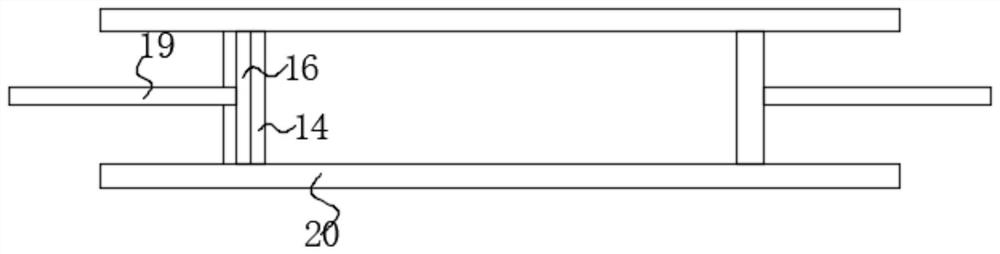

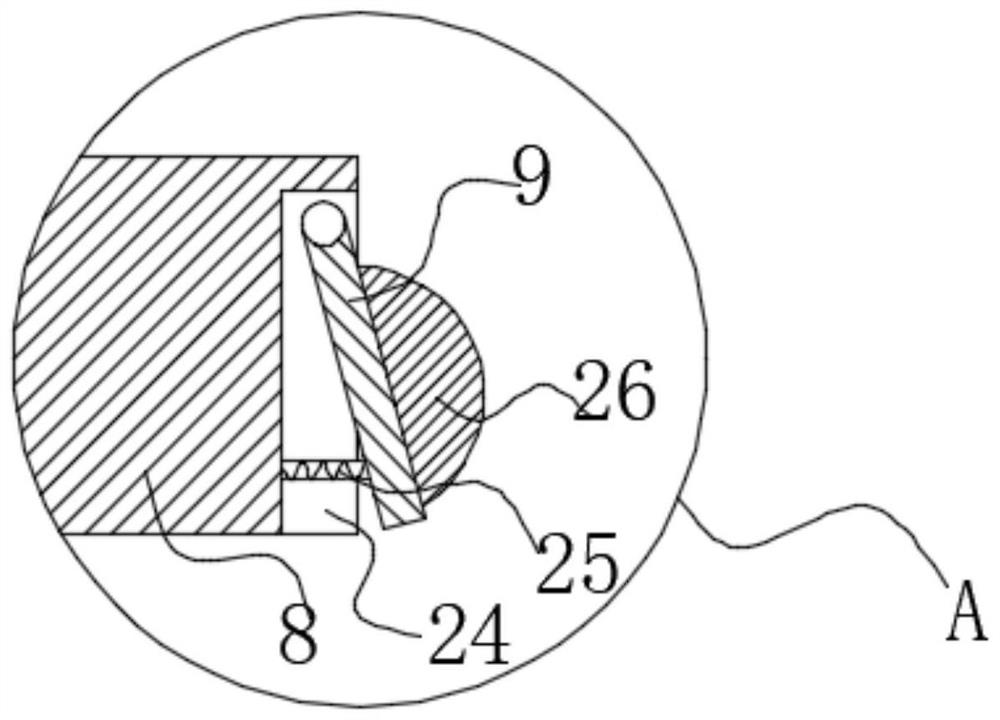

[0022] see figure 1 , the present embodiment, a kind of drying equipment of inorganic thermal insulation board body, comprises frame 1, the drying oven 11 that is installed on described frame 1, is installed on described frame 1 and penetrates in described drying box 1. In the box 11, there is a conveying device for conveying the sheet material 5 and a drying device arranged in the drying box 11. Two side sealing plates 16 are installed in a horizontal sliding manner in the drying box 11, and the side sealing plates A U-shaped clamp seat 14 is fixedly installed in the middle of 16, and the two side sealing plates 16 are driven to slide by the first cylinder 18, and the first cylinder 18 is fixedly assembled on the outer wall of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com