Method for detecting weaving density of three-dimensional woven fabric based on deep learning

A technology of density detection and deep learning, which is applied in machine learning, instrumentation, computing, etc., can solve problems such as time-consuming and labor-intensive, the impact of 3D fabric manufacturing quality, and relying on the subjective identification of inspectors, so as to improve quality and reduce human subjectivity The effect of interference and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The deep learning-based three-dimensional fabric weaving density detection method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

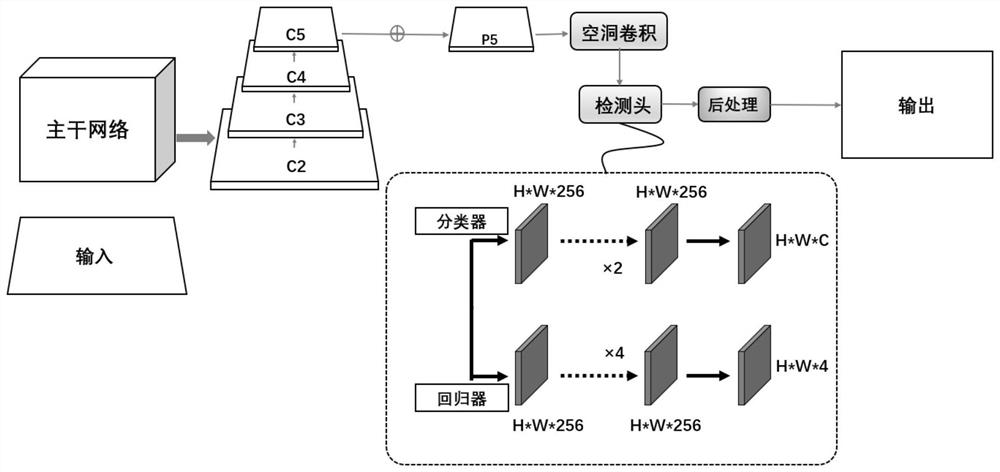

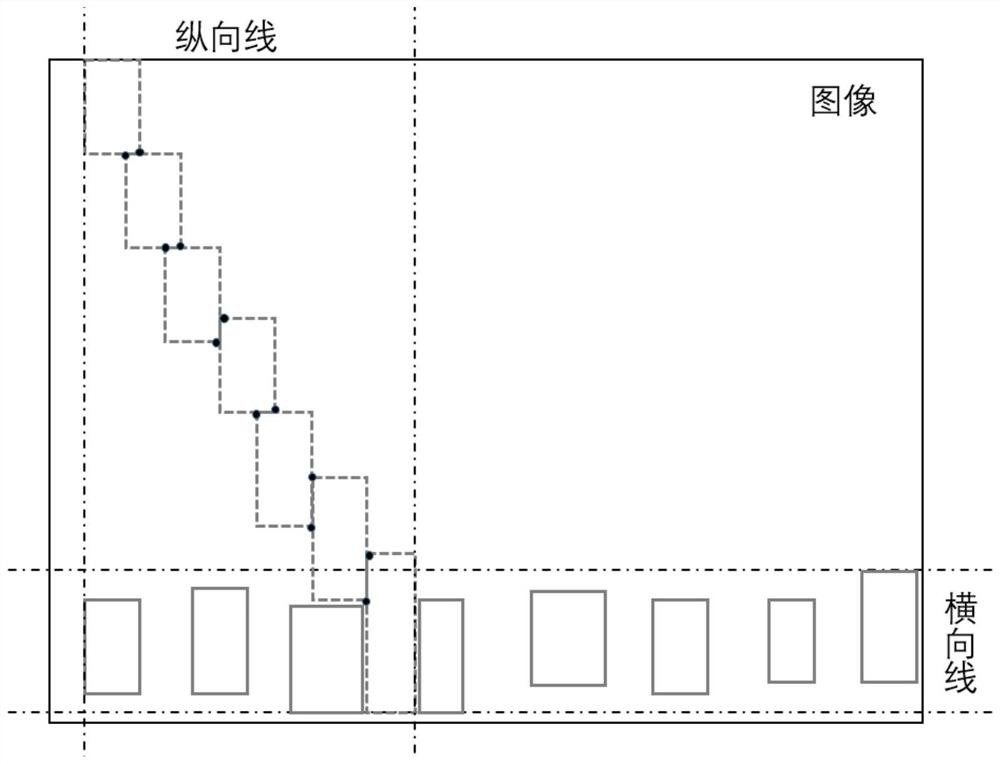

[0025] In the three-dimensional weaving density detection method based on deep learning of the present invention, the density calculation of vertical and horizontal lines is based on a deep learning network, and each vertical and horizontal line monomer can be accurately detected by analyzing the vertical and horizontal line categories and position coordinates , and then calculate the density value through the distribution of each vertical and horizontal line on the image.

[0026] A method for detecting the weaving density of three-dimensional fabrics based on deep learning, comprising the steps of:

[0027] Step 1. Collect the surface image of the three-dimensional fabric, mark the category and position of the collected surface image of the three-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com