PCB impedance control method, device and equipment and readable storage medium

A technology of impedance control and control, which is applied in the secondary processing of printed circuits, electrical components, and printed circuit manufacturing, etc. It can solve problems affecting PCB impedance matching, uneven solder mask thickness, and affecting impedance values, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

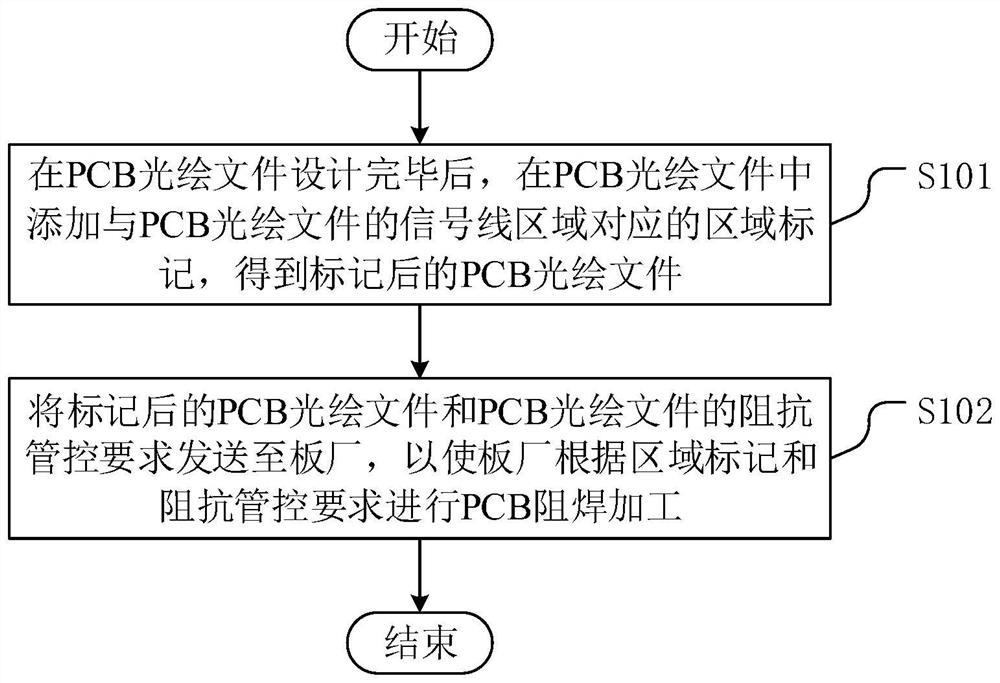

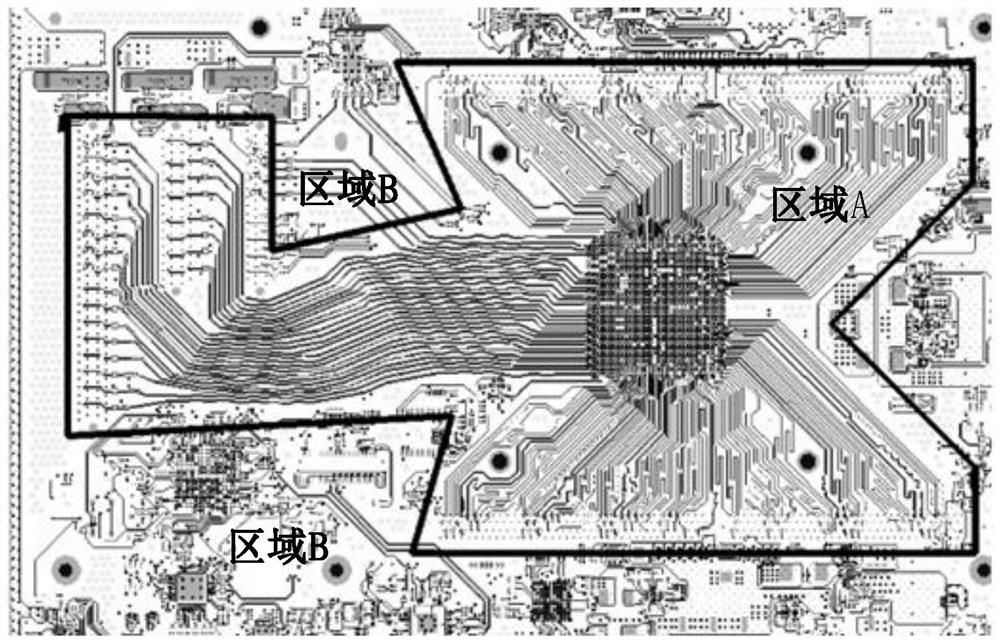

[0044] figure 1 A flow chart of the first PCB impedance control method provided in the embodiment of the present application; figure 2 It is a schematic diagram of a marked PCB gerber file provided in the embodiment of this application.

[0045] like figure 1 As shown, the method for PCB impedance control provided by the embodiment of the present application includes:

[0046] S101: After the design of the PCB light-drawing file is completed, an area mark corresponding to the signal line area of the PCB light-drawing file is added to the PCB light-drawing file to obtain a marked PCB light-drawing file.

[0047] S102: Send the marked PCB light drawing file and the impedance control requirements of the PCB light drawing file to the board factory, so that the board factory performs PCB solder mask processing according to the area marking and impedance control requirements.

[0048] Impedance matching is mainly used on transmission lines to achieve the purpose that all high-...

Embodiment 2

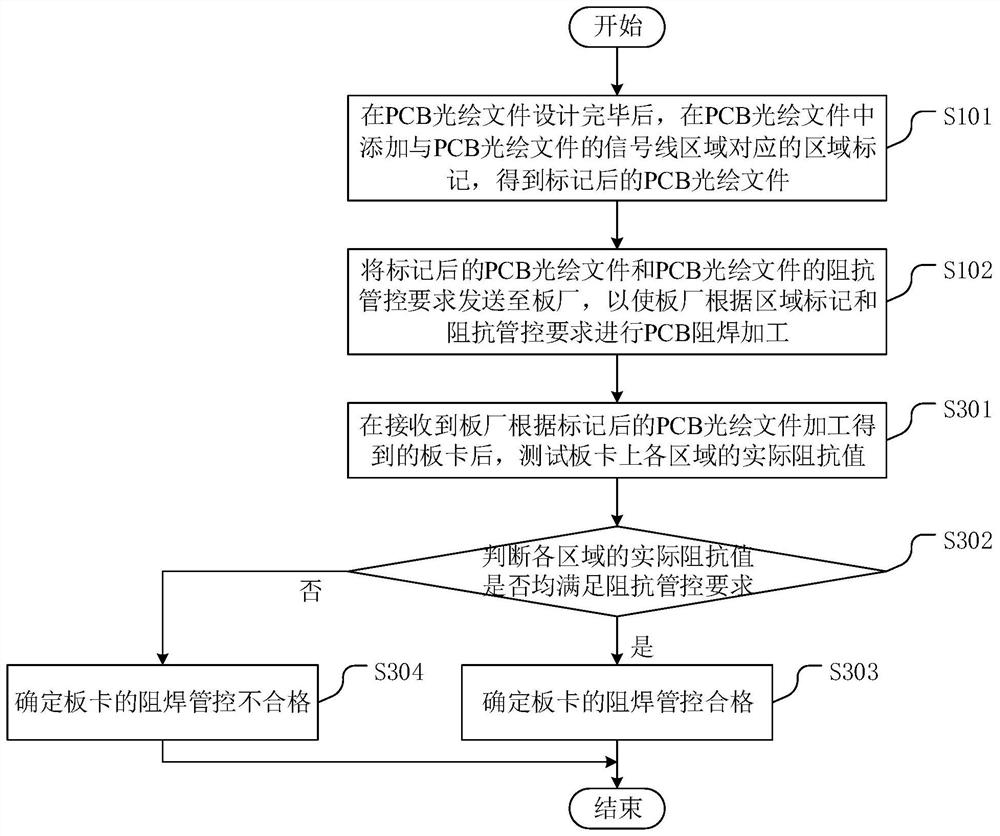

[0057] image 3 A flowchart of another PCB impedance control method provided by the embodiment of the present application; Figure 4 It is a schematic diagram of an impedance test principle provided in the embodiment of the present application.

[0058] On the basis of the above examples, if image 3 As shown, the method for PCB impedance control provided by the embodiment of the present application includes:

[0059] S101: After the design of the PCB light-drawing file is completed, an area mark corresponding to the signal line area of the PCB light-drawing file is added to the PCB light-drawing file to obtain a marked PCB light-drawing file.

[0060] S102: Send the marked PCB light drawing file and the impedance control requirements of the PCB light drawing file to the board factory, so that the board factory performs PCB solder mask processing according to the area marking and impedance control requirements.

[0061] S301: After receiving the board processed by the boa...

Embodiment 3

[0072] Figure 5 It is a flow chart of the third PCB impedance control method provided by the embodiment of this application.

[0073] On the basis of the above examples, if Figure 5 As shown, the method for PCB impedance control provided by the embodiment of the present application includes:

[0074] S101: After the design of the PCB light-drawing file is completed, an area mark corresponding to the signal line area of the PCB light-drawing file is added to the PCB light-drawing file to obtain a marked PCB light-drawing file.

[0075] S102: Send the marked PCB light drawing file and the impedance control requirements of the PCB light drawing file to the board factory, so that the board factory performs PCB solder mask processing according to the area marking and impedance control requirements.

[0076] S301: After receiving the board processed by the board factory according to the marked PCB photo-painting file, test the actual impedance value of each area on the board. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com