Rapid cross-linking and degradable peg powder and its application

A fast, starchy technology, applied in applications, surgery, drug delivery, etc., can solve the problems of no interaction between tissues, inconvenient use, easy to break, etc., and achieve good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

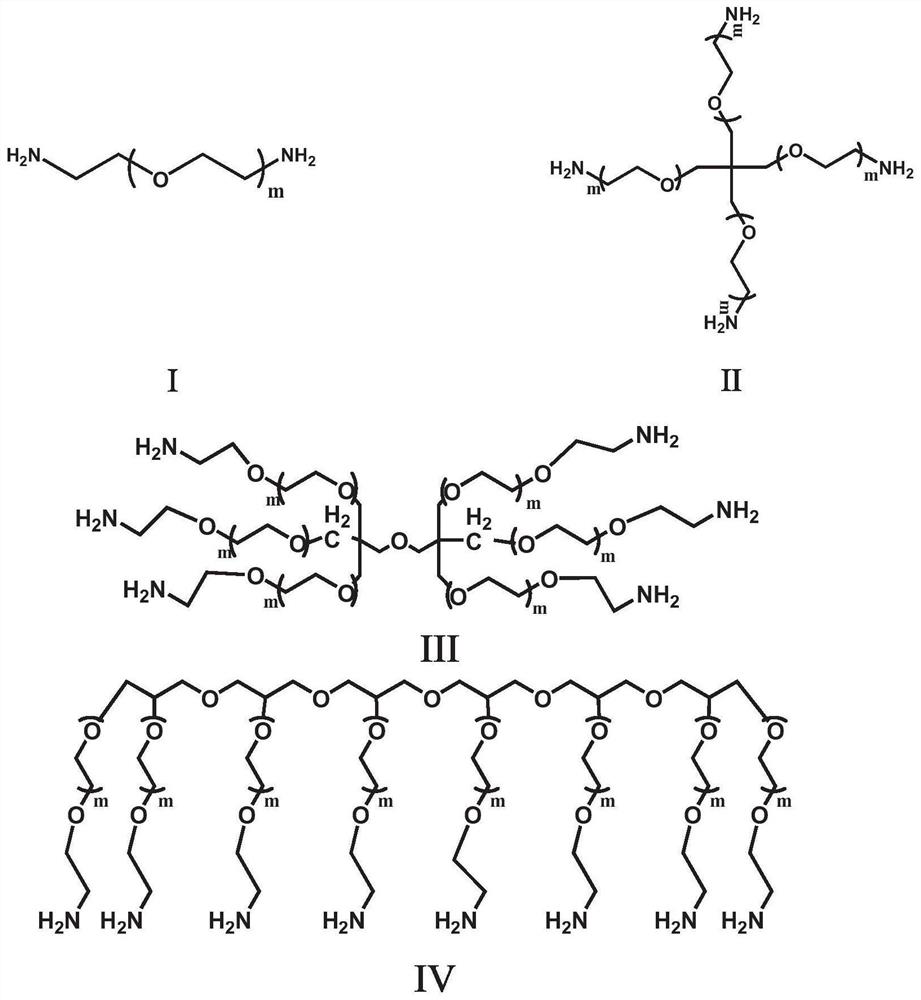

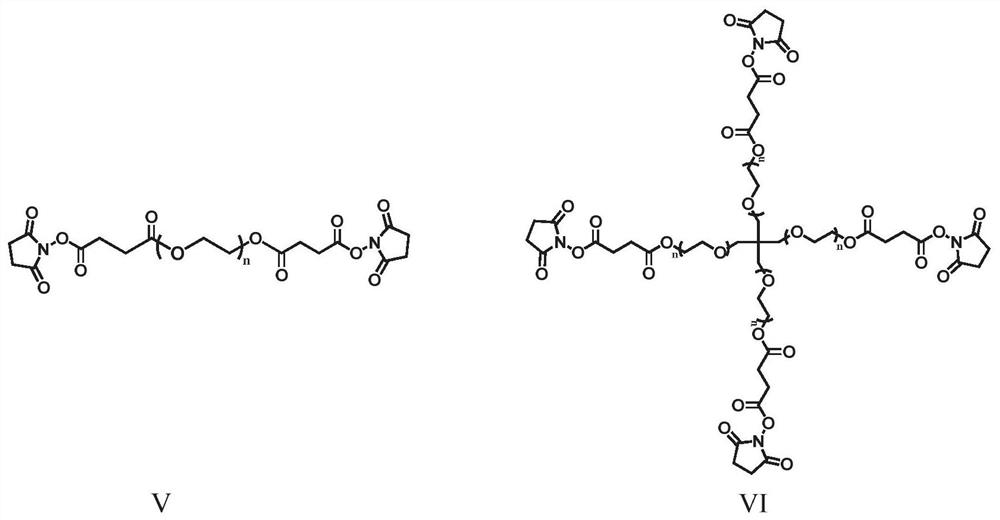

[0048] Weigh 130mg four-arm polyethylene glycol amino group (as shown in formula II, wherein m is 36), the particle size is 1 μm, and weigh 120mg four-arm polyethylene glycol succinimide ester (as shown in formula VI, Wherein, n is 46), the particle size is 2 μm, two kinds of PEG powders and 100 mg of Fuhetai degradable hemostatic powder are mixed uniformly to obtain composite hemostatic powder.

[0049] Degradation test: Put the composite hemostatic powder after water absorption into 10 times the mass of PBS solution, then put it into a constant temperature shaker at 37±1°C, and observe the gel sample in the buffer solution at a speed of 100r / min. Change the situation, until the time of centrifugation and no precipitation is seen, which is recorded as the gel in vitro degradation time.

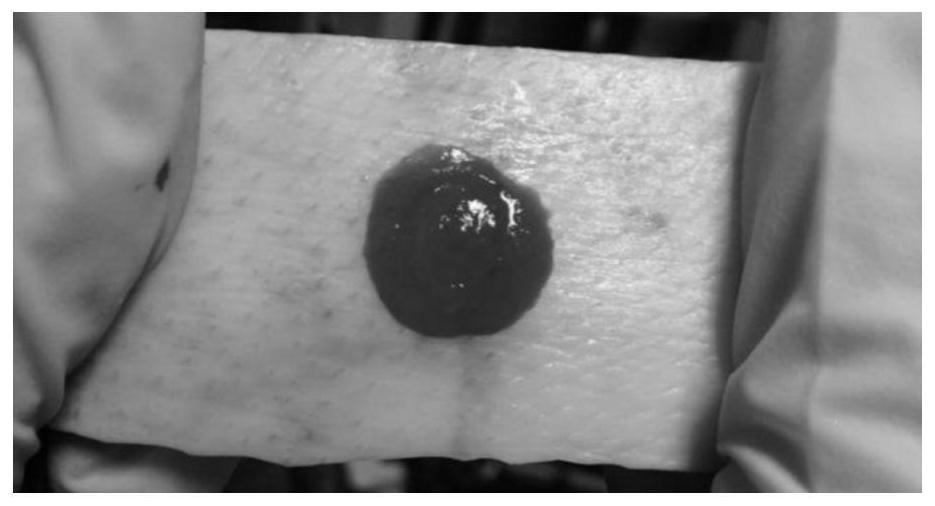

[0050] Absorption test: Mix a certain quality of hemostatic powder and spread it in a petri dish, and add ultrapure water to the petri dish to immerse the hemostatic powder. The gelled hemos...

Embodiment 2

[0057] Weigh 200mg four-arm polyethylene glycol amino group (as shown in formula II, wherein m is 123), and the particle size is 0.2 μm, weigh 200mg four-arm polyethylene glycol succinimide ester (as shown in formula VI) , where n is 112), the particle size is 0.5 μm, and the two kinds of PEG powders are mixed with 200 mg of melast quick-acting hemostatic powder uniformly to obtain compound hemostatic powder.

[0058] The composite hemostatic powder prepared in this example has a water absorption capacity of 150 times, which is far greater than the water absorption capacity (53 times) of the single commercially available Methast quick-acting hemostatic powder. It is attached to the surface of the skin, and the in vitro degradation time is 3 days.

Embodiment 3

[0060] Weigh 100mg six-arm polyethylene glycol amino group (as shown in formula III, wherein m is 38), the particle size is 0.2 μm, and weigh 200mg two-arm polyethylene glycol succinimide ester (as shown in formula V) , where n is 46), the particle size is 1.5 μm, and the two kinds of PEG powders are mixed with 500 mg Arista TM hemostatic powder uniformly to obtain a composite hemostatic powder.

[0061] The composite hemostatic powder prepared in this example has a water absorption capacity of 73 times, which is close to the water absorption capacity (70 times) of the single commercially available Arista TM hemostatic powder. On the surface of the skin, the in vitro degradation time was 4 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap