Automatic gluing device

A gluing device and automatic technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of difficult control of gluing quality, high labor intensity, and low work efficiency, so as to achieve better gluing effect, Improve production efficiency and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

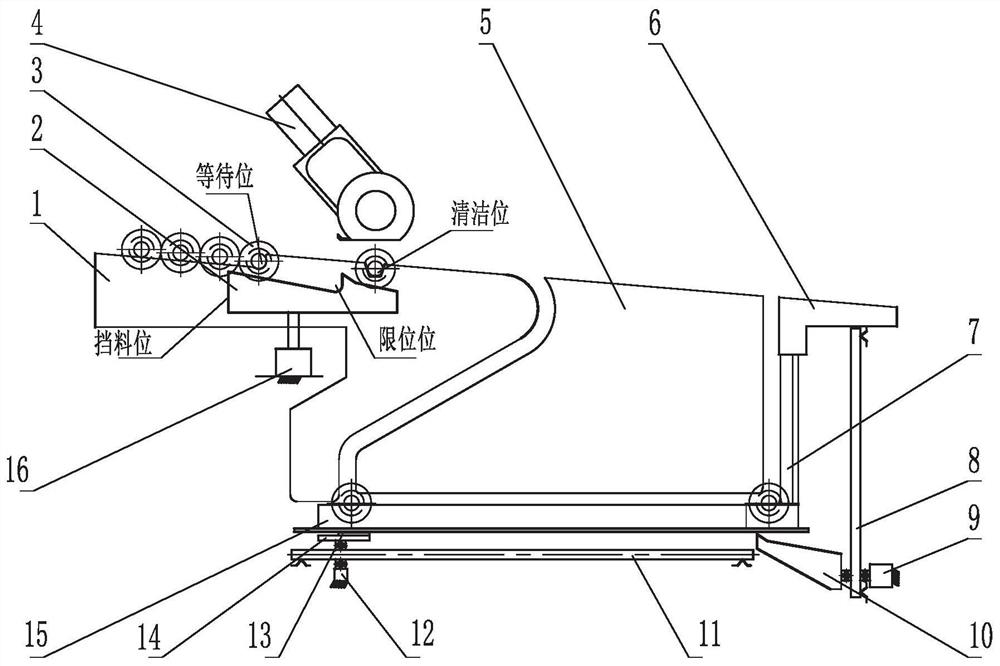

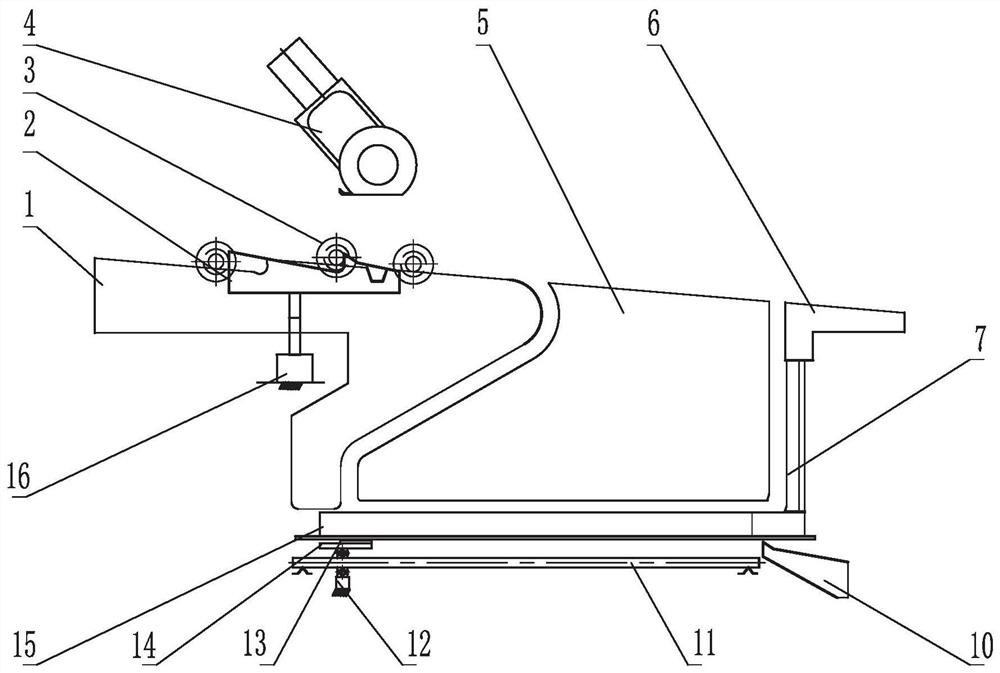

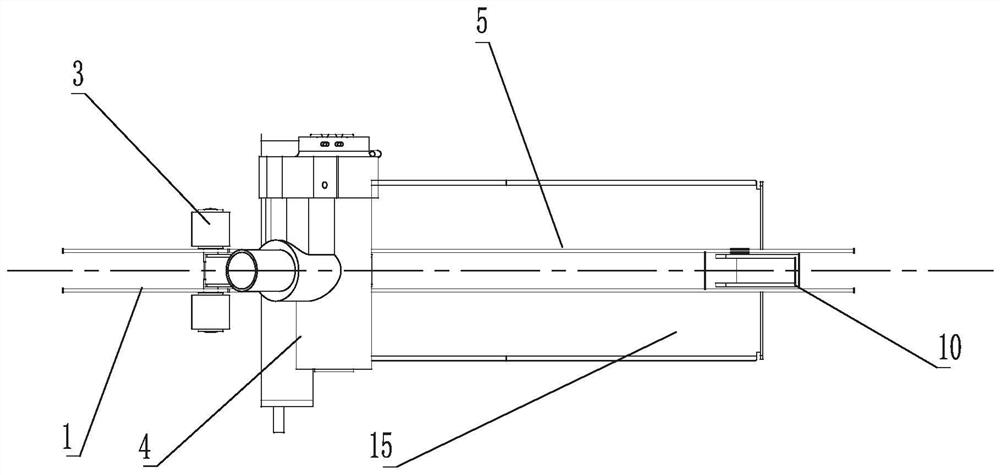

[0028] like Figure 1 to Figure 6 As shown, the automatic gluing device of the present invention is provided with glue box 15 on the frame, and glue box 15 is made of two square boxes arranged side by side in parallel, there is a certain interval between the two square boxes, and the top roller 3 can be placed Scroll horizontally in a straight line on two square boxes. The sponge and the cloth layer covering the sponge are placed in each square box. The square box is equipped with a liquid inlet, through which a certain volume of glue liquid is injected into the square box. The square box also has an overflow port, and the overflow port will exceed the The glue liquid of the set capacity is discharged, and the volume of the glue liquid in the square box remains unchanged. One end position below the glue box 15 is provided with a magnet block 13, and the magnet block 13 is controlled by a magnet drive mechanism to slide linearly along the length direction of the glue box 15. ...

Embodiment 2

[0039] As another embodiment, the difference between Embodiment 2 and Embodiment 1 lies in that the structure of the top roller feeding device is different. Specifically, a top roller feeding device is provided above the glue box. The top roller feeding device includes a feed raceway plate and an intermediate raceway plate. As for the vertical discharge device at the tail end of the glue box, it can be replaced by other ways to take out the top rollers. Moreover, the discharge raceway plate can also be replaced by other means, as long as the top roller needs to be taken out at the tail end of the glue box, it is no longer limited to the vertical discharge device and the discharge raceway plate of Embodiment 1. The matching relationship between the feed raceway plate and the top roller ejection frame remains unchanged.

Embodiment 3

[0041] As another embodiment, the difference between Embodiment 3 and Embodiments 1 and 2 lies in that the structure of the top roller feeding device is different. Specifically, a top roller feeding device is arranged above the glue box, and the top roller feeding device includes a feed raceway plate, and the two veneer tops of the feed raceway plate form the raceway of the top rollers, and the contours of the two veneer tops It consists of two inclined raceways at the front and rear. The end of the rear raceway is located above the beginning of the glue box, and the top roller directly enters the beginning of the glue box after passing through the rear raceway. The matching relationship between the feed raceway plate and the top roller ejection frame remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com