Energy-saving glue coating machine for stone machining

A technology of stone processing and gluing machine, which is applied in the direction of coating and surface coating liquid device, etc., which can solve the problems of high maintenance cost, waste of glue, and cumbersome process, so as to improve the gluing process and effect and reduce work Good process and gluing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

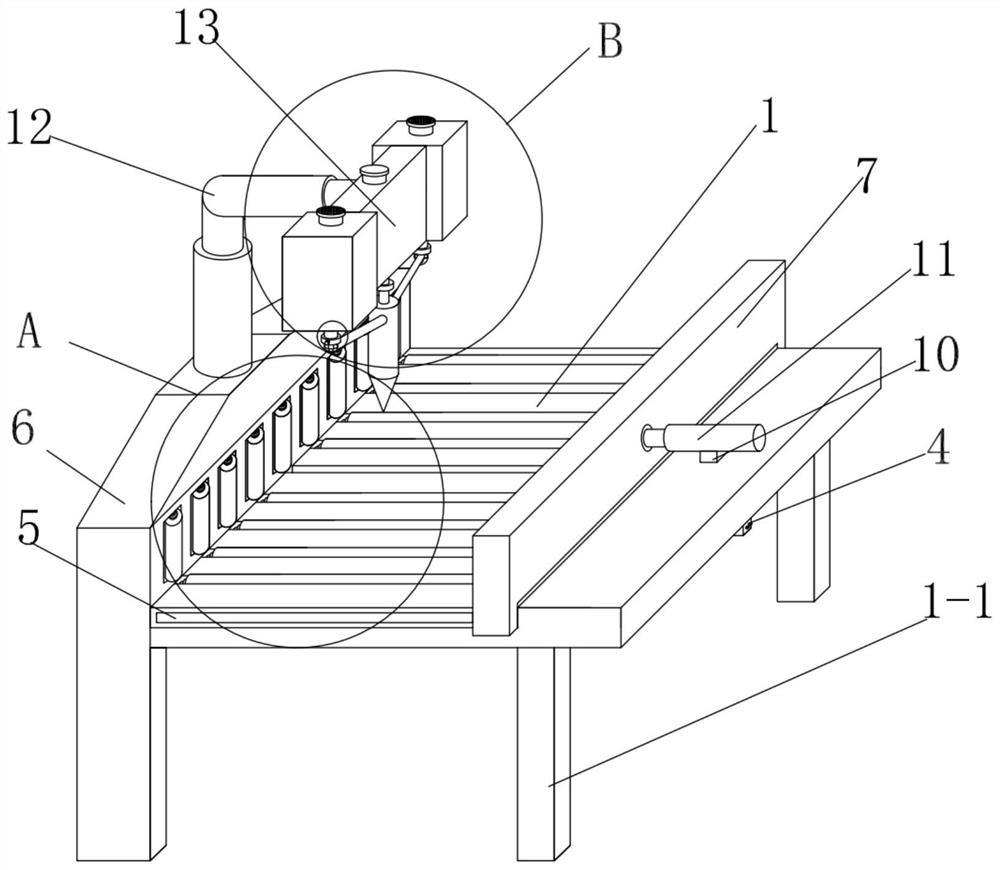

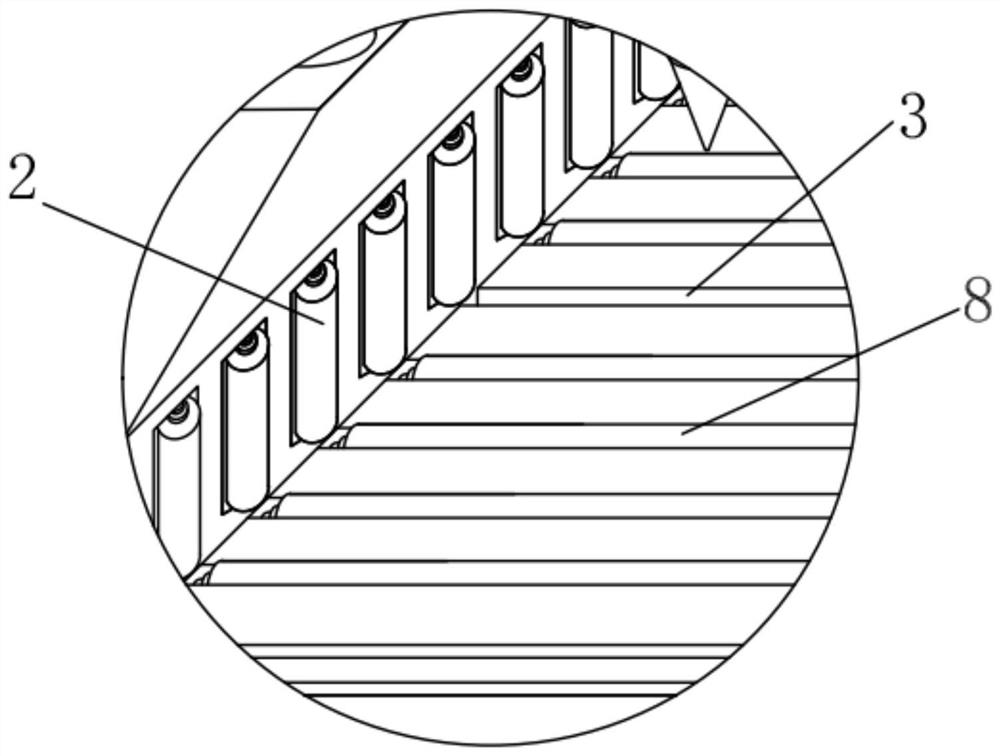

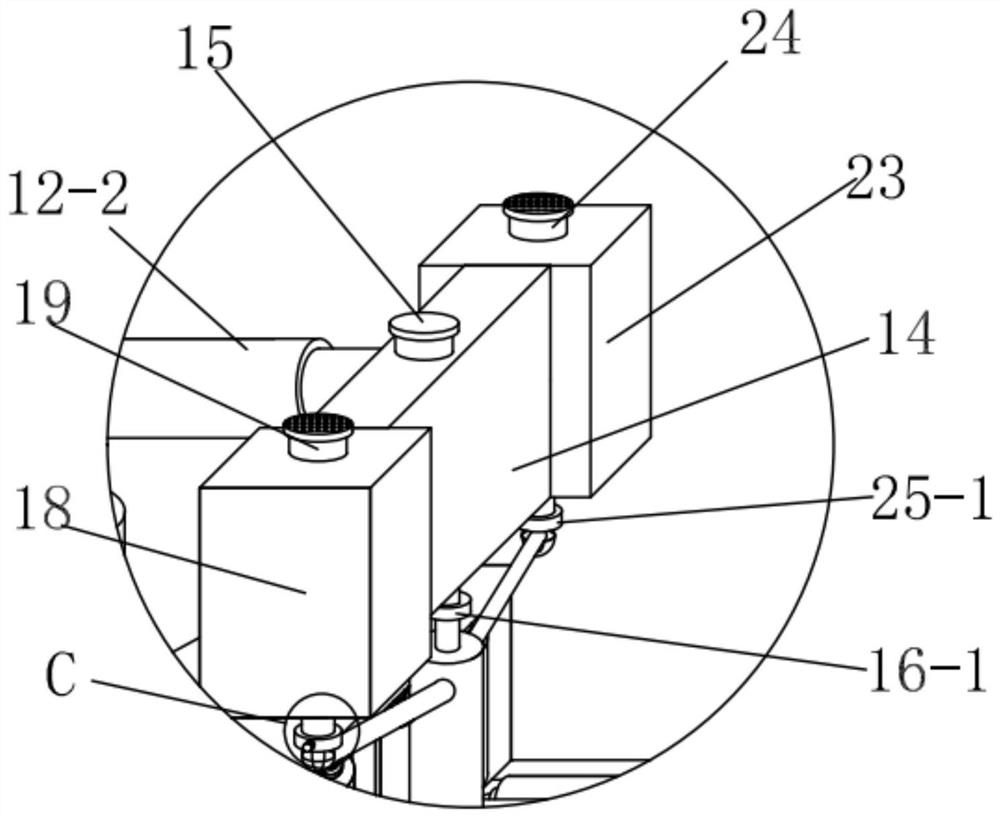

[0028] Such as Figure 1-Figure 11 Shown:

[0029]An energy-saving gluing machine for stone processing, including a workbench 1, a clamping mechanism I6, a clamping mechanism II7, a moving device 12, and a gluing mechanism 13. Leg 1-1, the workbench 1 is half-embedded with a set of auxiliary round rollers I2, the inside of the workbench 1 is provided with a fixed seat I2-1, the auxiliary round roller I2 and the fixed seat I2-1 The space is movably connected by a group of bearings I2-2, the center of the workbench 1 is provided with a glue-coated seam 3, and a collection tank 4 is provided below the glue-coated seam 3, and a drawer is arranged in the collection chamber 4 Slot 4-1, chute 5 is provided on both sides of the workbench 1, and the upper part of the workbench 1 is respectively provided with a clamping mechanism I6 and a clamping mechanism II7, and the clamping mechanism I6 and clamping mechanism II7 A group of auxiliary round rollers II8 are semi-embedded respective...

Embodiment 2

[0033] Such as Figure 1-Figure 11 Shown:

[0034] An energy-saving gluing machine for stone processing, including a workbench 1, a clamping mechanism I6, a clamping mechanism II7, a moving device 12, and a gluing mechanism 13. Leg 1-1, the workbench 1 is half-embedded with a set of auxiliary round rollers I2, the inside of the workbench 1 is provided with a fixed seat I2-1, the auxiliary round roller I2 and the fixed seat I2-1 The space is movably connected by a group of bearings I2-2, the center of the workbench 1 is provided with a glue-coated seam 3, and a collection tank 4 is provided below the glue-coated seam 3, and a drawer is arranged in the collection chamber 4 Slot 4-1, chute 5 is provided on both sides of the workbench 1, and the upper part of the workbench 1 is respectively provided with a clamping mechanism I6 and a clamping mechanism II7, and the clamping mechanism I6 and clamping mechanism II7 A group of auxiliary round rollers II8 are semi-embedded respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com