Sealant nozzle of coating machine

A coating machine and glue nozzle technology, which is applied to the surface coating liquid device, coating, etc., can solve the problem of uneven glue output from the glue nozzle, and the hollow glass cavity is easy to produce moisture, etc., to achieve glue output The effect of uniform amount, consistent width and stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

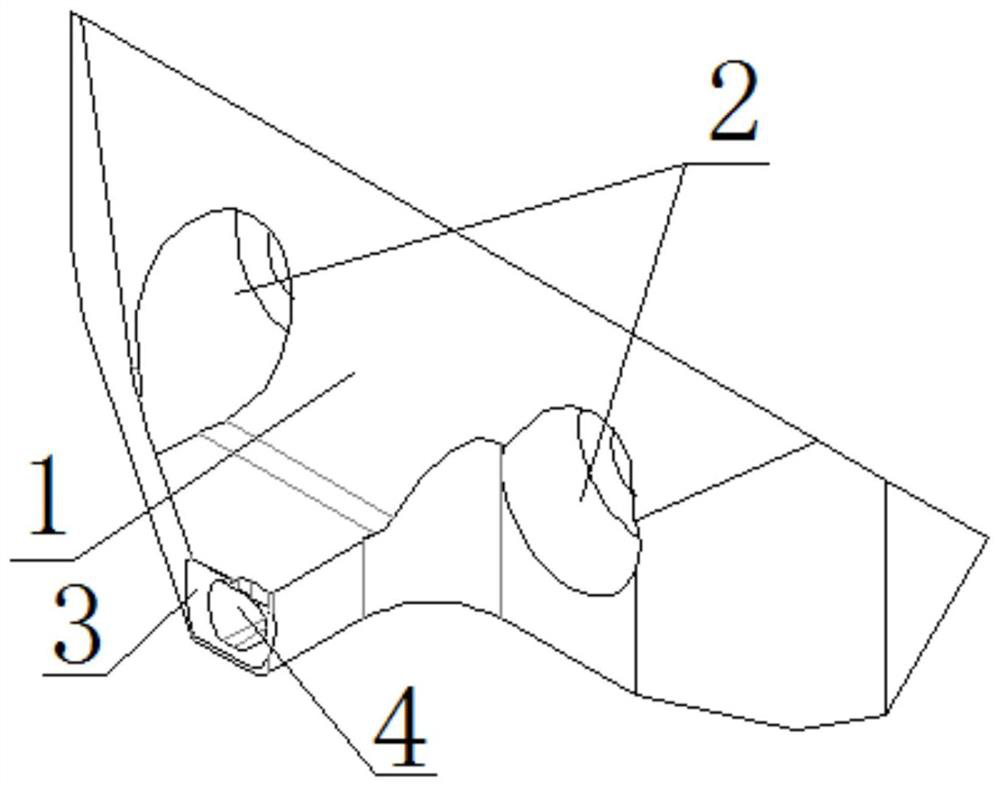

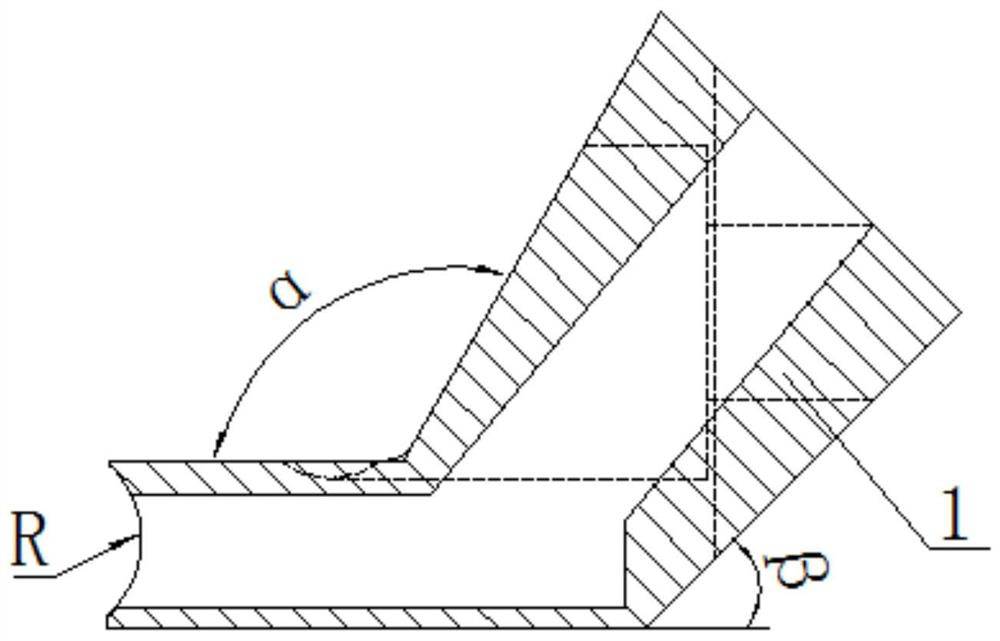

[0018] Such as Figure 1-2 As shown, a coating machine nozzle includes a body 1, a nozzle 3 is provided on the body 1, positioning holes 2 are provided on both sides of the nozzle 3, and a nozzle hole 4 is provided inside the nozzle 3 , the edge of the outer wall of the nozzle 3 is designed in an arc shape, the body 1 and the nozzle 3 are designed to form an angle α, and the nozzle 3 and the horizontal line are designed to form an angle β.

[0019] The nozzle hole 4 is designed as a through hole.

[0020] The arc R of the mouthpiece 3 is 2.5-3mm.

[0021] The included angle α between the rake angle of the body 1 and the mouthpiece 3 is 110-120°.

[0022] The included angle β between the relief angle of the body 1 and the horizontal line is 40-45°.

[0023] The body 1 is made of wear-resistant steel.

[0024] Since the front angle of the body 1 and the nozzle 3 are designed at an angle of 110-120°, the amount of sealant extruded from the nozzle hole 4 of the nozzle 3 is uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com