A kind of screen plate and preparation method thereof

A screen and screen technology, applied in the field of screen and its preparation, can solve the problems of easy formation of burrs, impact, poor sealing effect, etc., achieve the effect of uniform glue output and overcome burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

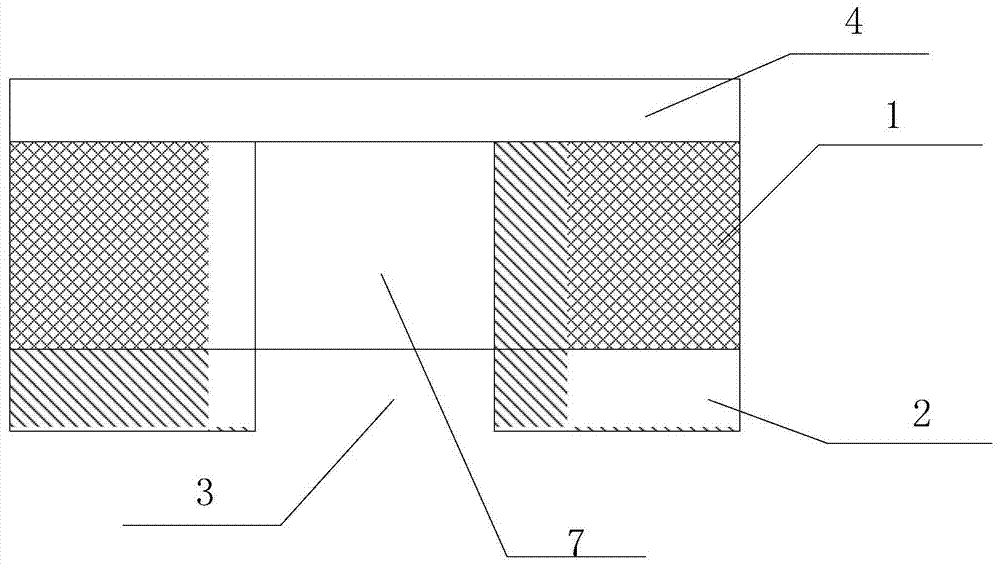

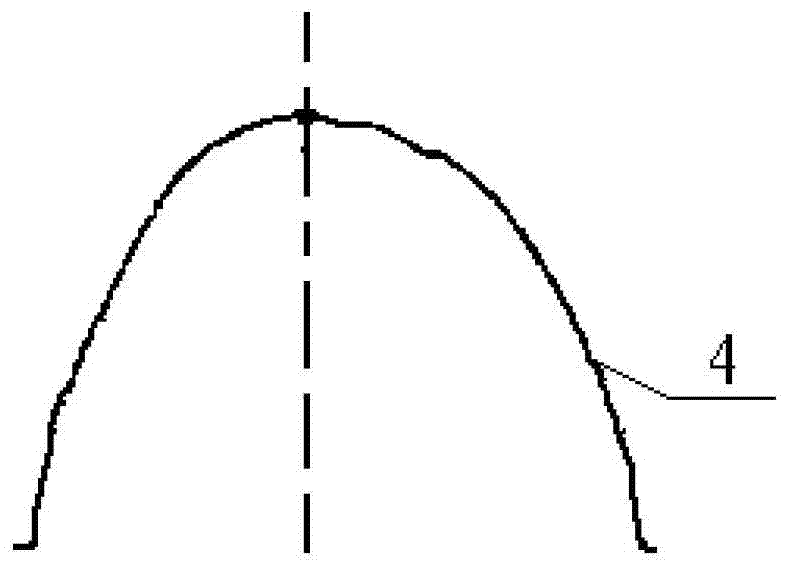

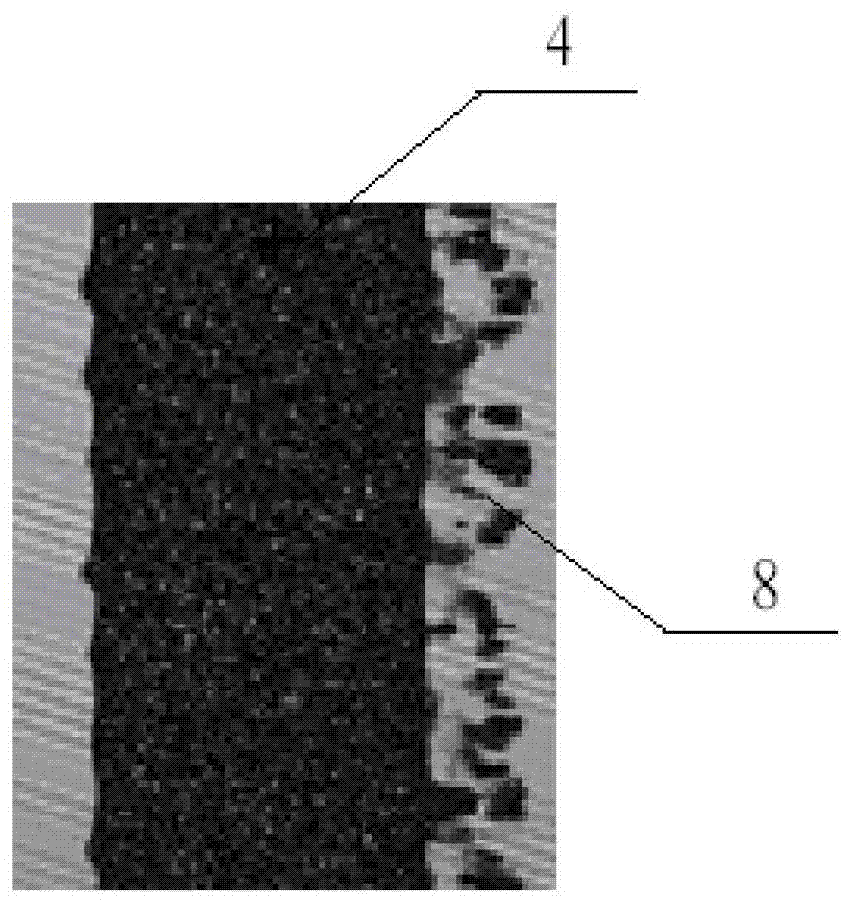

[0043] Such as Figure 4 As shown, the present embodiment provides a screen, including a screen 1 and a pattern layer 2 located on one side of the screen 1, the pattern layer 2 includes at least one opening forming a pattern; the opening includes at least two sub-openings; The size of the sub-openings decreases successively from close to the screen to away from the screen, wherein the substance to be printed is printed through the pattern layer 2 from the side of the screen opposite to the pattern layer 2 .

[0044] Wherein, openings are provided with the first sub-opening 21, the second sub-opening 22, the third sub-opening 23, and the fourth sub-opening 24 in order from close to the screen 1 to away from the screen 1, and the widths are d1, d2, d3, respectively. d4. It should be understood that the pattern is formed by a hollow area, and each pattern includes at least one opening, and the shape of the opening is also different according to the pattern, and the width here re...

Embodiment 2

[0054] The present embodiment provides a kind of preparation method of screen plate, comprises the following steps:

[0055] Coating photosensitive glue on one side of the screen;

[0056] Exposing and developing the side of the screen that is coated with the photosensitive adhesive to form a sub-opening pattern farthest from the screen, and performing at least one exposure and developing from the opposite side of the screen that is coated with the photosensitive adhesive to form At least one sub-opening; wherein, the size of the sub-openings decreases sequentially from close to the screen to away from the screen;

[0057] or,

[0058] At least two exposures and developments are carried out from the opposite side of the screen coated with the photosensitive adhesive to form at least two sub-openings; wherein the size of the sub-openings decreases sequentially from close to the screen to away from the screen.

[0059] specifically,

[0060] S1. Coating photosensitive glue on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com