Automatic sorting device of trichosanthes kirilowii Maxim fruit

An automatic sorting and trichosanthes technology, applied in the field of mechanical production equipment, can solve the problems of manpower consumption and low efficiency, and achieve the effect of improving efficiency, fast speed and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

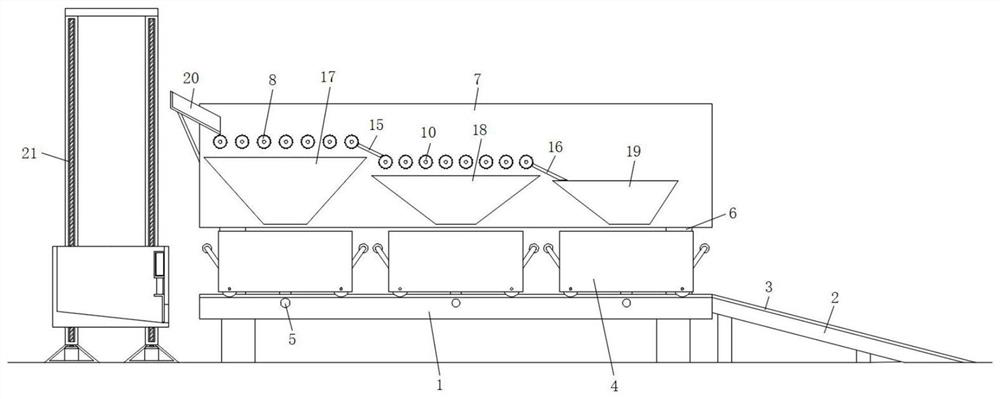

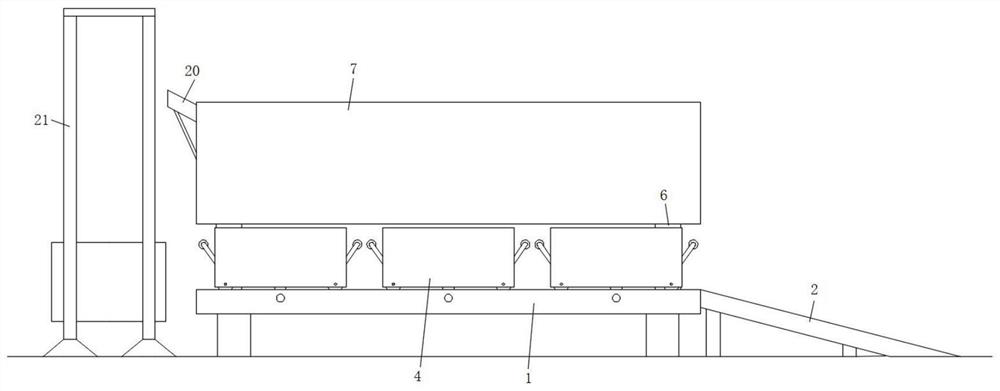

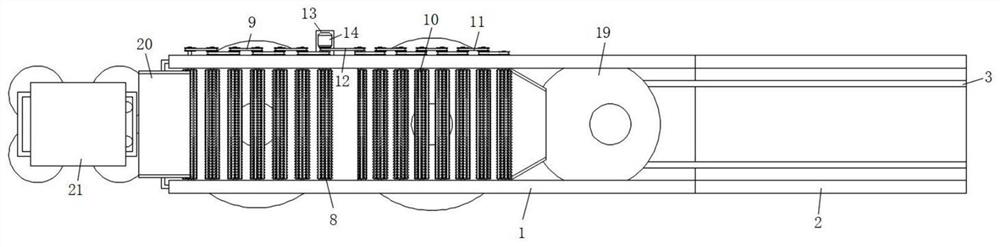

[0032] refer to Figure 1-7 , a kind of Trichosanthes fruit automatic sorting device, comprises sorting table 1, and one side of sorting table 1 is provided with unloading table 2, and unloading table 2 and sorting table 1 top front and rear sides are all provided with rolling groove 3, The rolling groove 3 is rollingly connected with the loading assembly 4, and the top of the sorting table 1 is also fixed with columns 6 on the front and rear sides. There are four columns 6 and they are fixed on the top surface of the sorting table 1 in a rectangular shape. The top surface of the column 6 is fixedly connected with a mounting plate 7, and a sorting roller-8 is also rotatably connected between the two mounting plates 7, and the rear sides of the adjacent two sorting rollers-8 all pass through the mounting plate 7 and pass through the Conveyor belt one 9 is rotationally connected, and the middle part of two mounting plates 7 is also rotationally connected with sorting roller 2 10...

Embodiment 2

[0034] Such as figure 1 , 2, 5 and 6, the present embodiment is basically the same as Embodiment 1. Preferably, the lifting and feeding assembly 21 includes a conical block 211, and the top surface of the conical block 211 is fixed with a lifting plate 212, and the inside of the lifting plate 212 is provided with a There is a mounting groove, and a screw rod 213 is rotatably connected between the bottom surface and the top surface of the mounting groove, and the inner bottom surface of the tapered block 211 is fixed with a servo motor 214 through screws, and the output ends of the servo motor 214 are fixed with the screw rod 213 connection, the outer wall of the screw rod 213 is also fixed with a mounting block 215 by threads, and the mounting blocks 215 are all slidably connected on the inner wall of the mounting groove, and a feeding dish 216 is also fixed between the four mounting blocks 215, and the upper end of the feeding dish 216 is close to the sorting One side of tab...

Embodiment 3

[0039] like figure 1 , 2 As shown in and 7, the present embodiment is basically the same as Embodiment 1. Preferably, there are three charging assemblies 4, and the charging assembly 4 includes a collection dish 41, and push handles 42 are fixed on both side walls of the collection dish 41 to collect A connecting block 43 is also fixed at the center of the bottom surface of the dish 41, and a rectangular groove is provided in the middle of the top surface of the sorting table 1 and the unloading table 2. The connecting block 43 is slidably connected in the rectangular groove, and the front and rear sides of the sorting table 1 are also connected A fixing hole is connected, and a fixing pin 5 is also connected between the connecting block 43 and the sorting table 1 .

[0040] In this embodiment, a fixed pin 5 is connected between the collection dish 41 and the sorting table 1, and the collection dish 41 is more stable when sorting the Trichosanthes fruit, which provides a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com