Automatic machining machine for forehead thermometer accessories

A technology of automatic processing and forehead temperature gun, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of low production efficiency, labor cost and processing cost increase, so as to improve production efficiency, reduce product processing time, reduce The effect of extra loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in the preferred embodiment are only for convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

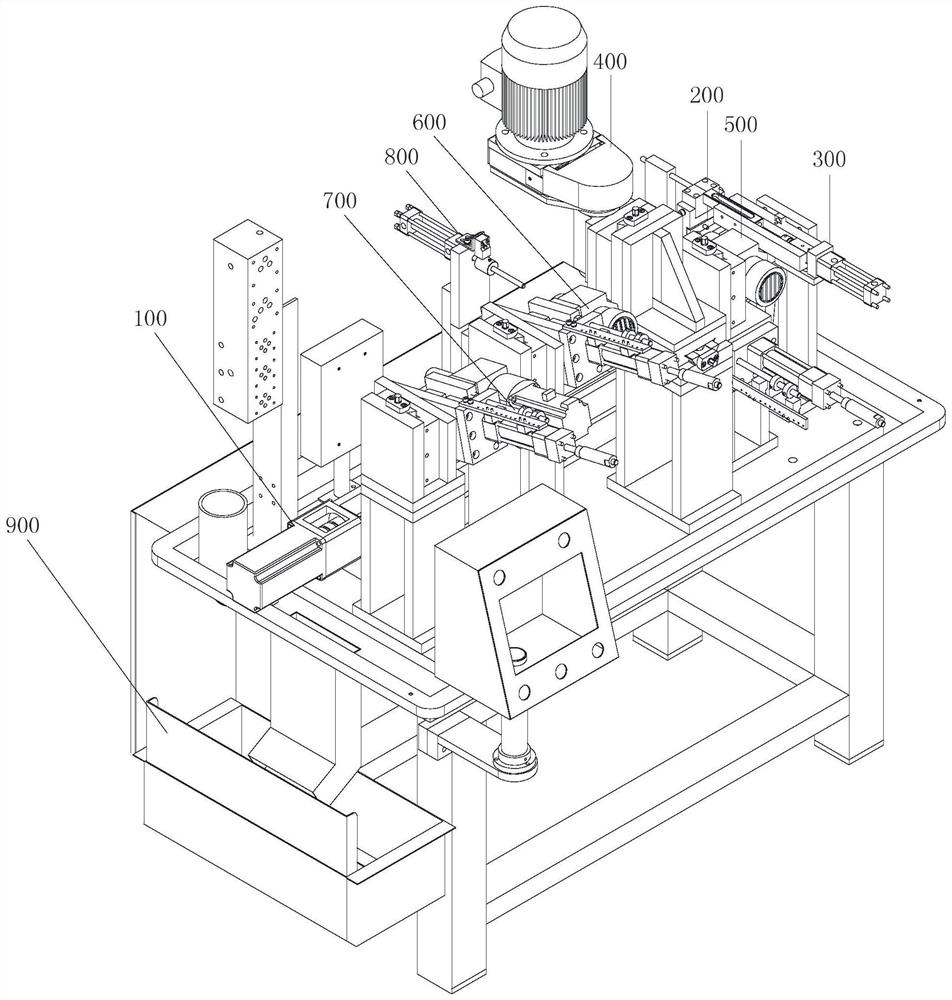

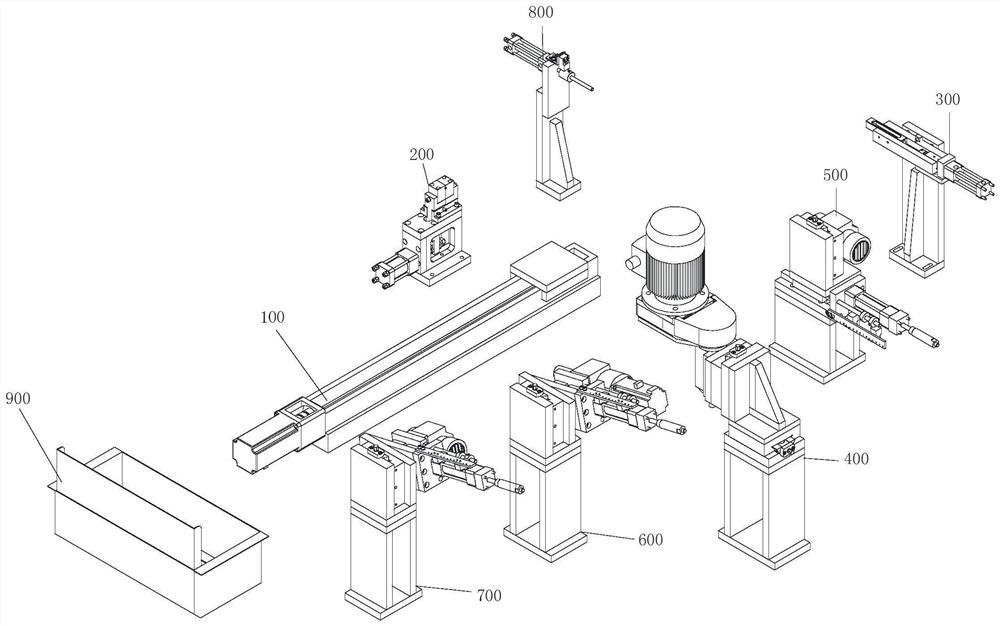

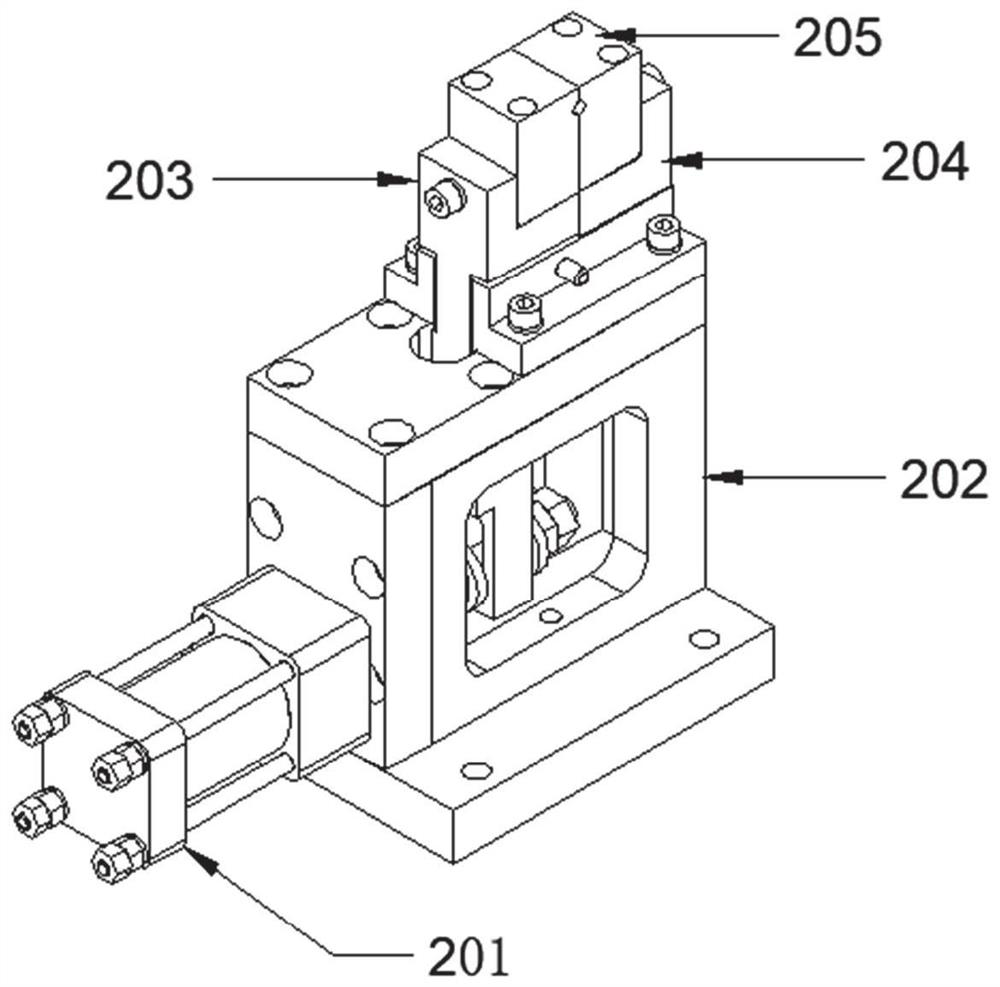

[0028] like Figure 1 to Figure 9 As shown, the present invention provides an automatic processing machine for forehead temperature gun accessories, including a spindle assembly 100, a clamp assembly 200, a feeding assembly 300, an unloading assembly 800, a milling assembly 400, a centering assembly 500, and a drilling assembly 600 And the tapping assembly 700, the clamp assembly 200 is connected with the spindle assembly 100 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com