Foaming preheating equipment for strip-shaped high-polymer material

A polymer material and strip-shaped technology, applied in the field of foaming preheating equipment, can solve the problems of unfavorable environmental protection and health impact, and achieve the effects of environmental protection, health protection and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

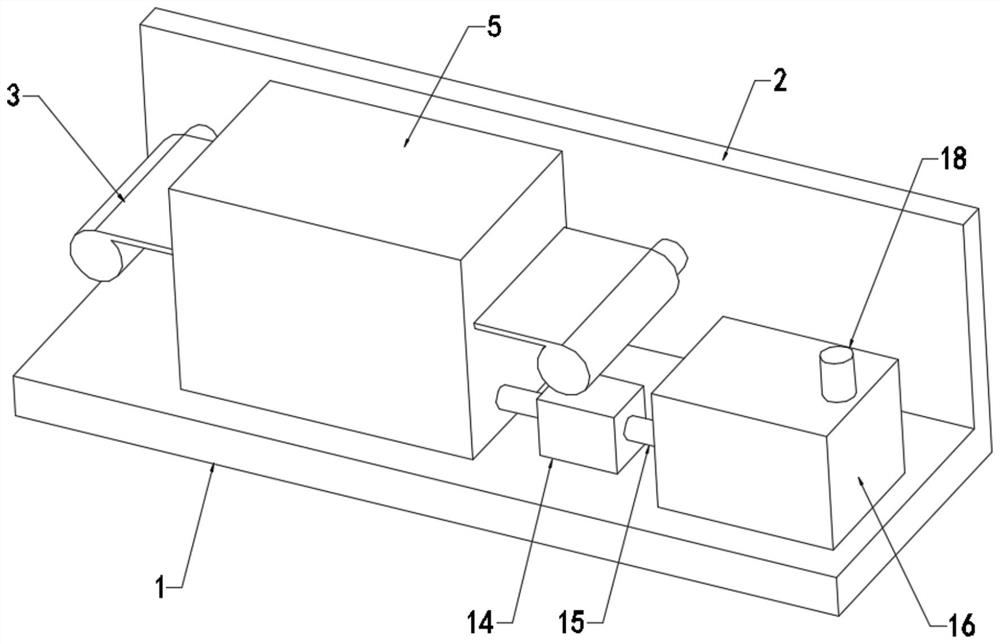

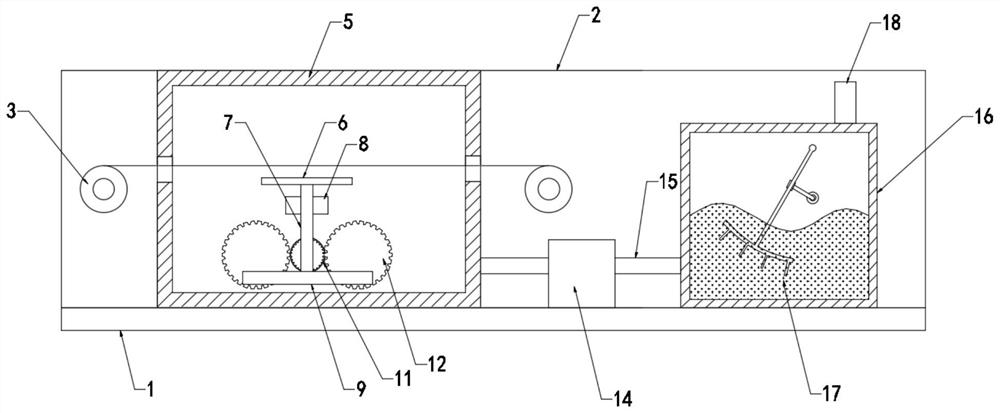

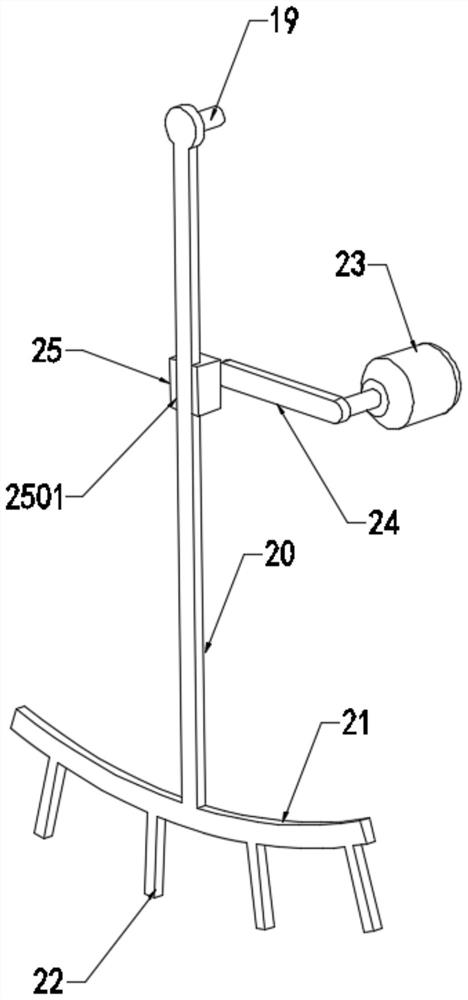

[0041] see Figure 1-8 , the present invention provides a technical solution: a foaming preheating equipment for strip-shaped polymer materials, including a base 1, a riser 2 is fixedly installed on the base 1, and two first rotating shafts are rotatably installed on the riser 2 3. There is a heating box 5 between the two first rotating shafts 3, a strip-shaped polymer material is wound around the first rotating shaft 3, and a heating device is arranged in the heating box 5; a ventilation pipe 15 is connected to the heating box 5 , the free end of vent pipe 15 is communicated with processing case 16, and vent pipe 15 is provided with air extraction pump 14, and processing case 16 top is communicated with exhaust pipe 18, and processing liquid 17 is provided with in processing case 16, and is fixedly installed in processing case 16 Central shaft 19 is arranged, and the first rotating block 20 is installed on the central shaft 19, and the stirring block 21 is fixedly installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com