Plastic rattan production equipment for rattan-plaited hanging chairs

A kind of production equipment and rattan technology, which is applied in the field of rattan plastic processing equipment, can solve the problems of troublesome rattan specification change operation, poor cooling effect of tubular rattan, etc., and achieve the effect of simple and convenient switching, maintaining pressure and easy switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

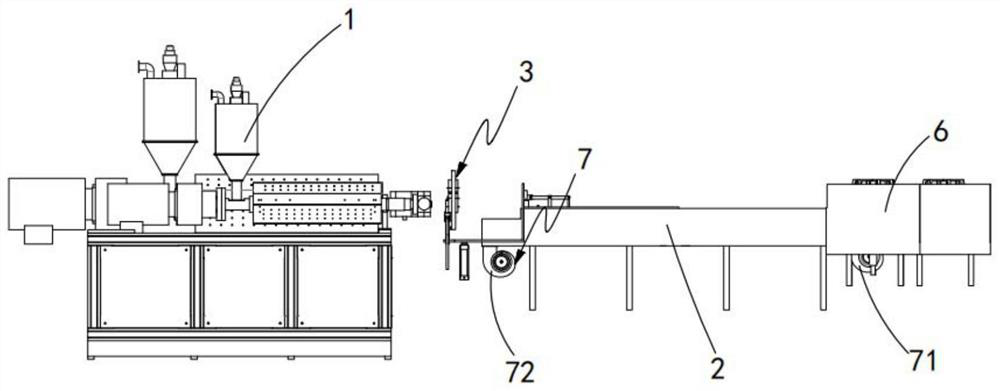

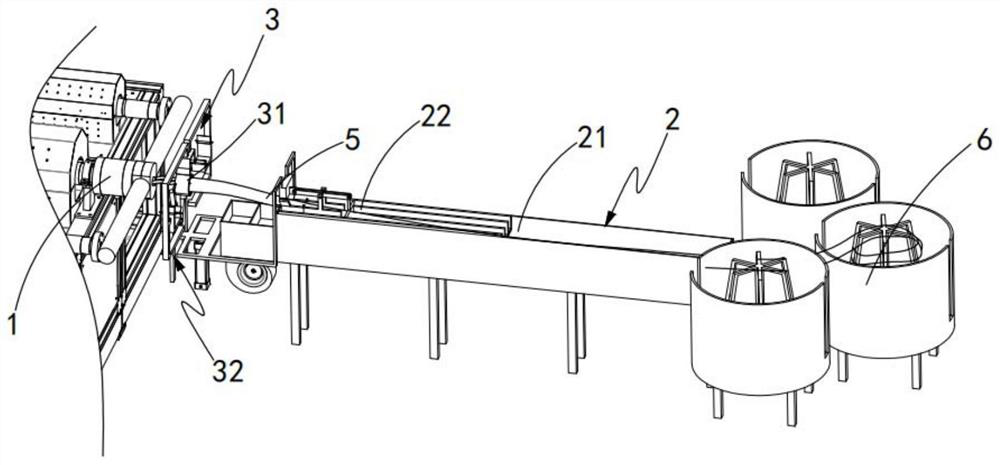

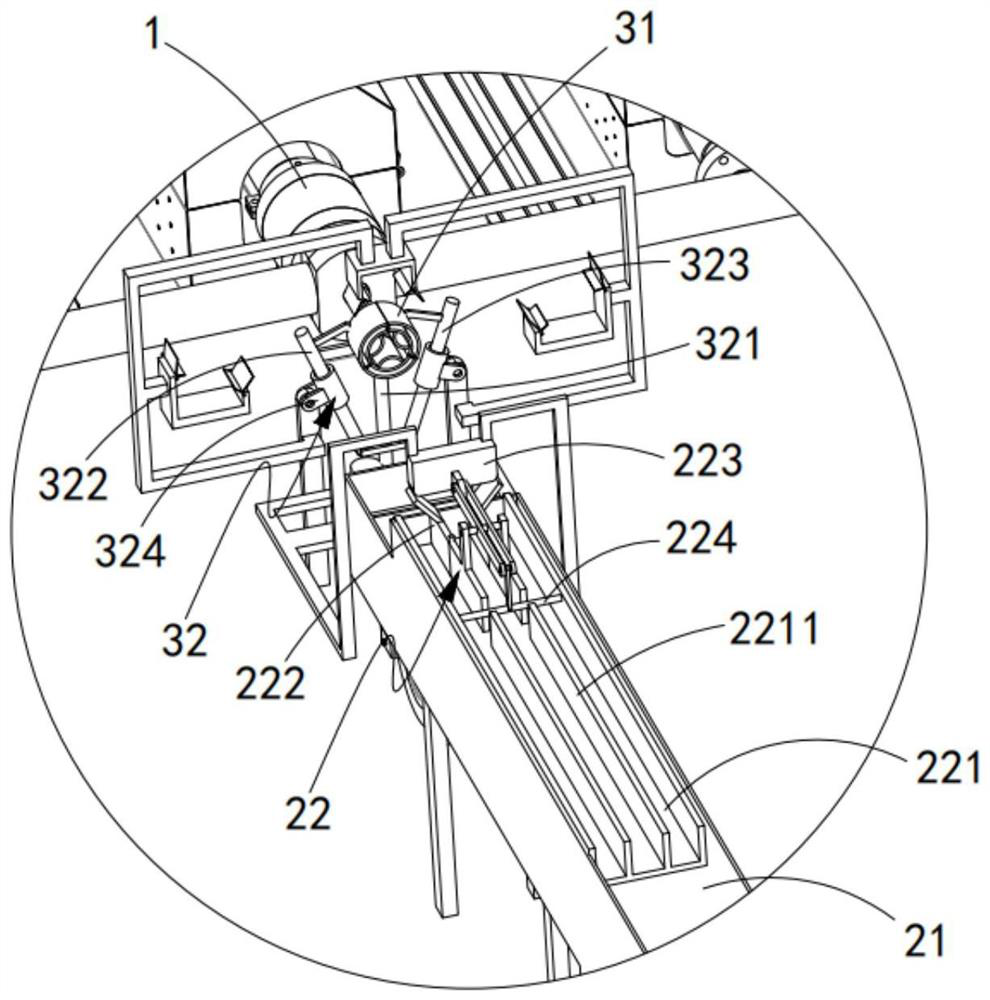

[0035] Such as Figures 1 to 7 As shown, a kind of plastic rattan production equipment for rattan hanging chairs includes a melting extrusion device 1 and a cooling device 2 for cooling and forming the rattan, and is characterized in that it also includes an output device installed on the melting extrusion device 1. The die head assembly 3 at the end, the die head assembly 3 includes a plurality of mold valve units 31, the melt extrusion device 1 extrudes the plastic rattan 4 with an arc-shaped cross section through the mold valve units 31, and the multiple mold valves After the petal units 31 are assembled into a ring, the melt extrusion device 1 extrudes a hollow cylindrical rattan tube 5 through the die assembly 3 .

[0036] Further, the die head assembly 3 further includes a mold clamping control unit 32 , and the mold clamping control unit 32 is connected to control the splicing or separation of each of the mold half units 31 .

[0037] It should be noted that when the d...

Embodiment 2

[0051] Such as Figure 8 , 9 , 10, wherein the same or corresponding parts as the first embodiment adopt the reference numerals corresponding to the first embodiment, for the sake of simplicity, only the differences from the first embodiment are described below: the second embodiment and the first embodiment The difference is:

[0052] In this embodiment, the mold clamping control unit 32 further includes a side baffle 1 325 and a side baffle 2 326, the side baffle 1 325 is set corresponding to the mold half unit 31 on the ejector pin 321, the The second side baffle 326 is set corresponding to the mold half unit 31 on the left connecting rod 322 and the right connecting rod 323. When the mold half unit 31 is separated, the first side baffle 325 and the second side baffle 326 fit together. The sides of the mold half unit 31 are closed.

[0053] It should be noted that no baffle plate is provided at the combined parts of the mold half units 31, so that when the mold half unit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap