Production system and production method of isobutyl acetate for high-end paint

A technology of isobutyl acetate and production system, which is applied in the separation/purification of carboxylate, preparation of carboxylate, chemical instruments and methods, etc., can solve problems such as increased production cost, and achieve low moisture content and low acid value. , the effect of high color quality

Active Publication Date: 2021-08-24

ZHEJIANG JIANYE CHEM

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this technical scheme, methyl acetate is used as raw material to replace acetic acid, which can reduce the acid content accordingly, but methyl acetate is rarer than

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

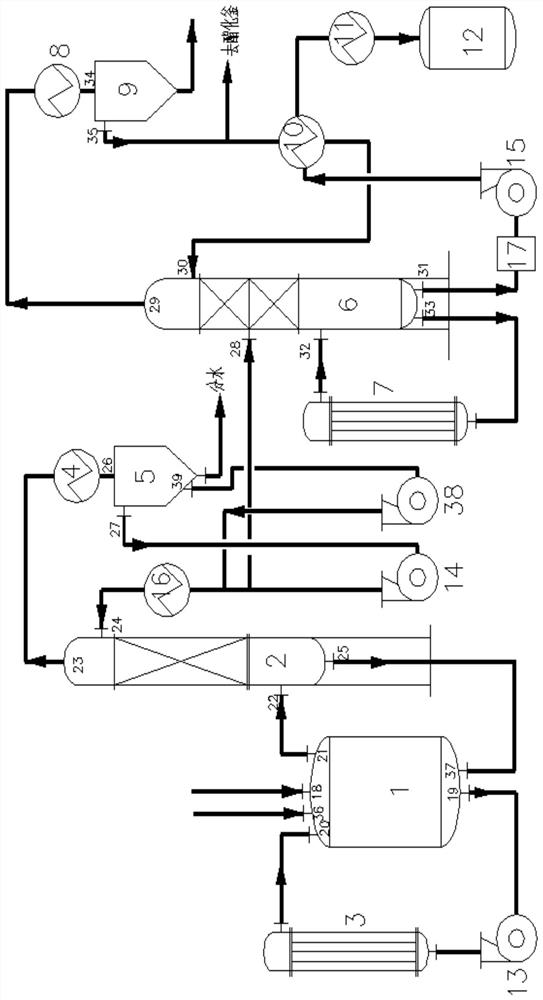

The invention relates to the technical field of production of isobutyl acetate, discloses a production system of isobutyl acetate for high-end paint, and aims at the problem that the requirements on the content of impurities such as alcohol, acid and water in isobutyl acetate for high-end paint are high. The production system comprises an esterification kettle, an esterification tower, an esterification phase splitter, a dehydration tower, a dehydration phase splitter and a finished product fine filter which are sequentially arranged along a material flowing direction, after reaction materials are added into the esterification kettle, the reaction product enters an esterification tower for preliminary separation and then enters an esterification phase splitter for water phase separation, the organic phase and the water phase flow back to the esterification tower according to a certain proportion, the other part of the organic phase enters the dehydration tower and then enters the dehydration phase splitter for water phase separation, and the organic phase flows back to the dehydration tower again, and isobutyl acetate is obtained from the bottom of the dehydrating tower. The production system can realize synchronous removal of impurities such as isobutanol, moisture and acid value in the isobutyl acetate so that the prepared isobutyl acetate is high in purity, low in isobutanol content, low in acid value, low in moisture content and high in color quality.

Description

technical field [0001] The invention relates to the technical field of isobutyl acetate production, in particular to a production system and a production method of isobutyl acetate for high-end paints. Background technique [0002] Isobutyl acetate is an important chemical raw material, mainly used in pharmaceuticals, fragrances, coatings, paints, leather, resin industries, and can also be used as a solvent for nitrocellulose and lacquers. Because isobutyl acetate has good solubility properties for many substances, it can be used as a diluent in the manufacture of nitrocellulose paint, acrylic paint, polyurethane paint, etc. in industry. These high-end paints can be used as aircraft wing coatings, artificial leather coatings, automotive coatings, etc. Isobutyl acetate is used as a diluent for high-end paints. There are strict requirements on the quality of isobutyl acetate finished products. It is necessary to ensure that the moisture content, residual acid content, residua...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C69/14C07C67/08C07C67/48C07C67/54

CPCC07C67/08C07C67/48C07C67/54C07C69/14Y02P20/10

Inventor 吴方丽金波王爱艳李晓晶赵素粉张磊

Owner ZHEJIANG JIANYE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com