Robot for checking and repairing underground drainage pipelines

A technology of underground drainage and robotics, which is applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of difficult to judge the specific location of the blockage, large amount of engineering, etc., and achieve the effect of easy cutting range, reasonable structure, and good obstacle removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

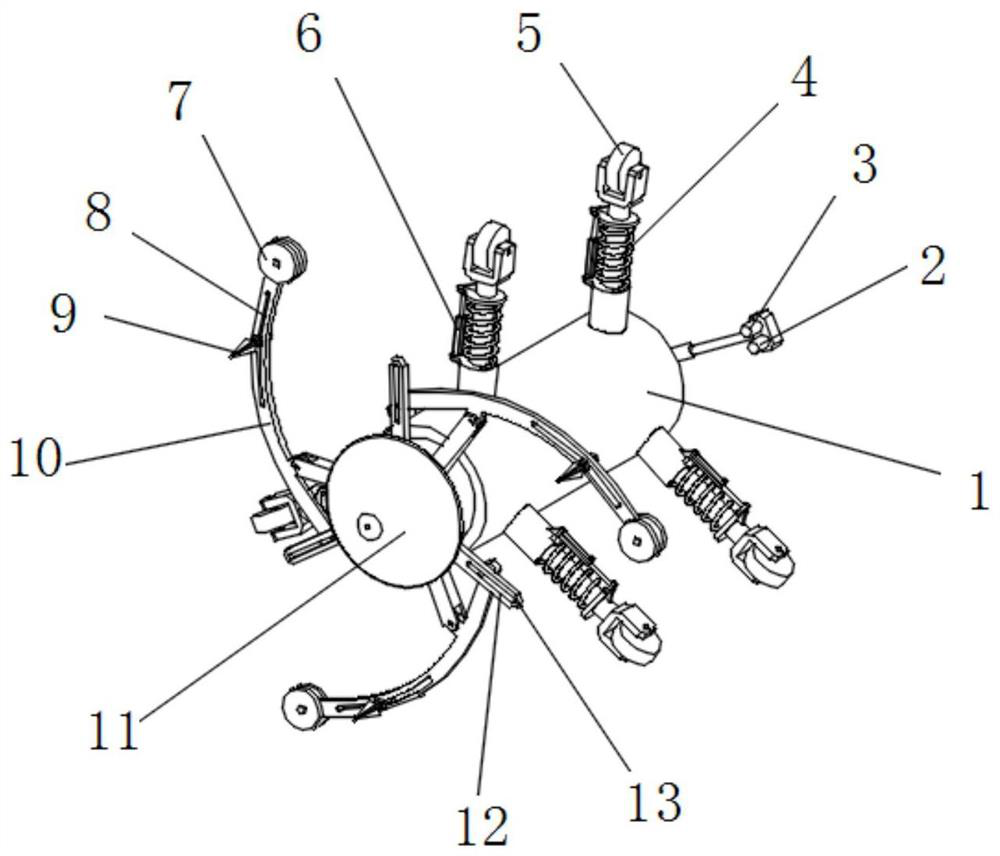

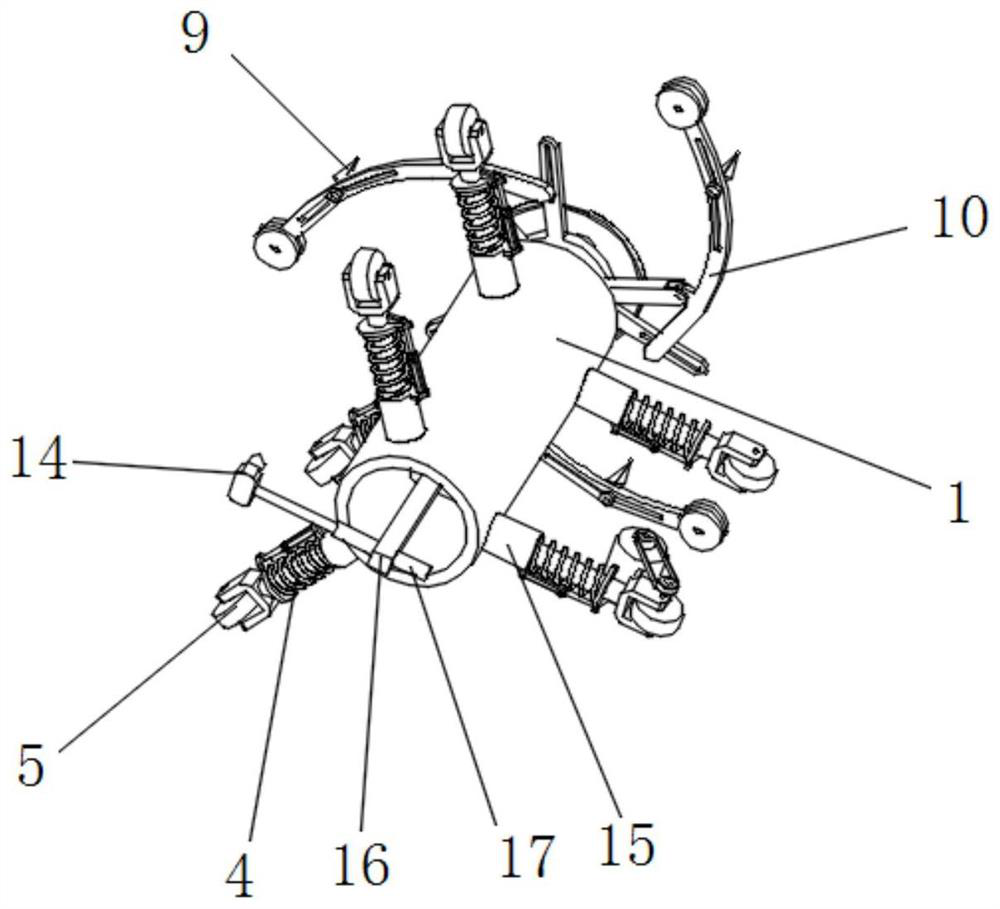

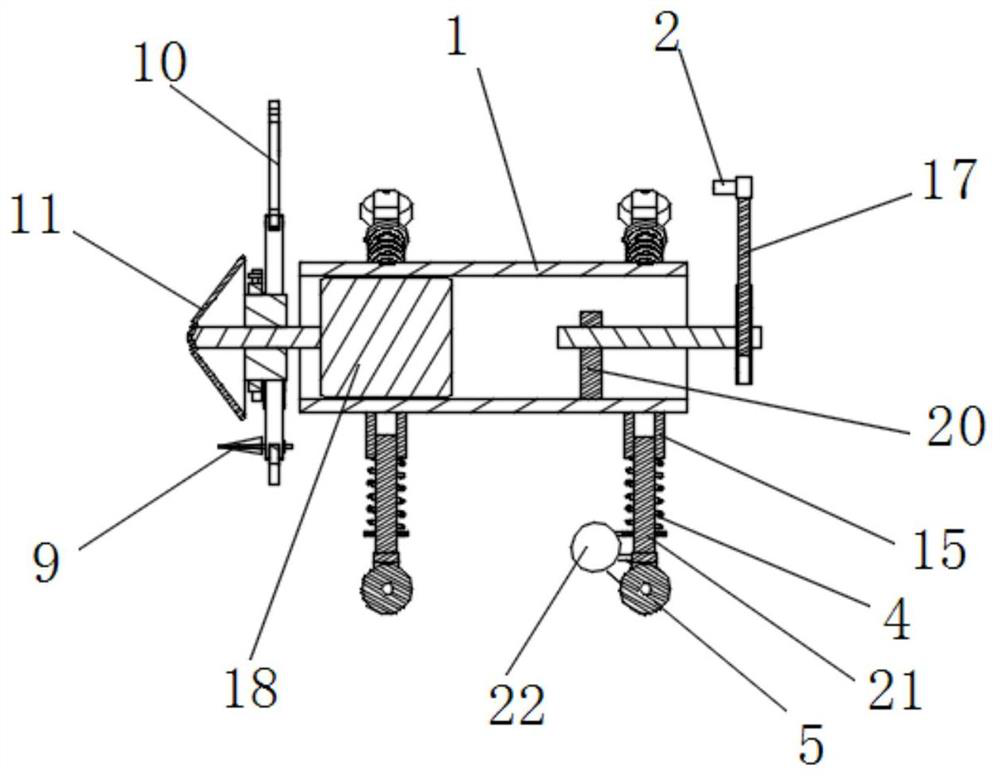

[0042] Example: Reference Figure 1-8 A robot for checking and repairing underground drainage pipes shown includes a body 1, which can be any tubular object in the prior art, such as a metal circular pipe.

[0043] A plurality of first sliding sleeves 15 are evenly and fixedly installed on the outer wall of the body 1, and first sliding rods 21 are all slidably installed on the plurality of first sliding sleeves 15. The spring 4 and the flange ring 30, the two ends of the spring 4 are in contact with the bottom side of the first sliding sleeve 15 and the top side of the flange ring 30 respectively. Sliding up, through the elastic force of multiple springs 4, the extension lengths of multiple first slide bars 21 can be freely adjusted respectively.

[0044] Rollers 5 are fixedly mounted on the bottom ends of the plurality of first slide bars 21 , and the machine body 1 is moved by the plurality of rollers 5 .

[0045] One side of one of the rollers 5 is fixedly equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com