Distributed step blasting equipment and blasting method

A step blasting and distributed technology, applied in the field of blasting, can solve problems such as impact, poor operation of blasting devices, adverse effects of facilities, etc., and achieve the effect of preventing a large amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

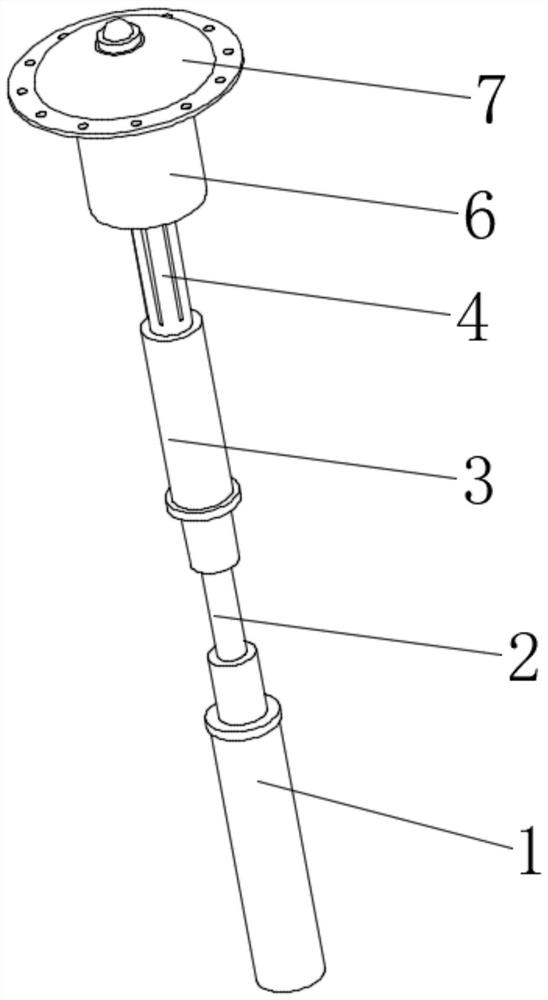

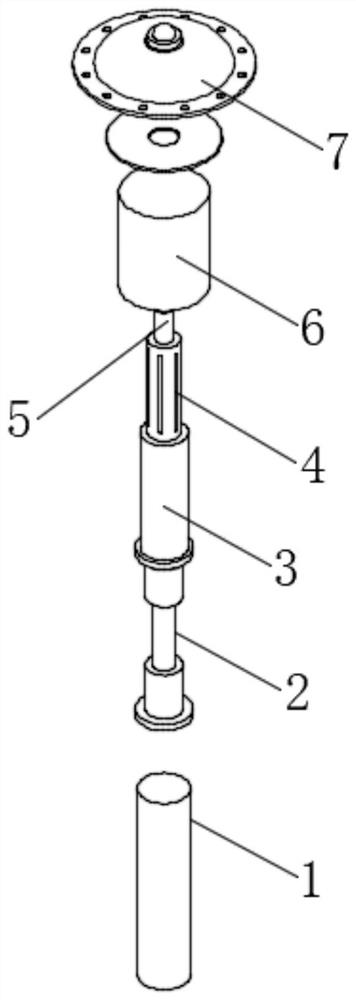

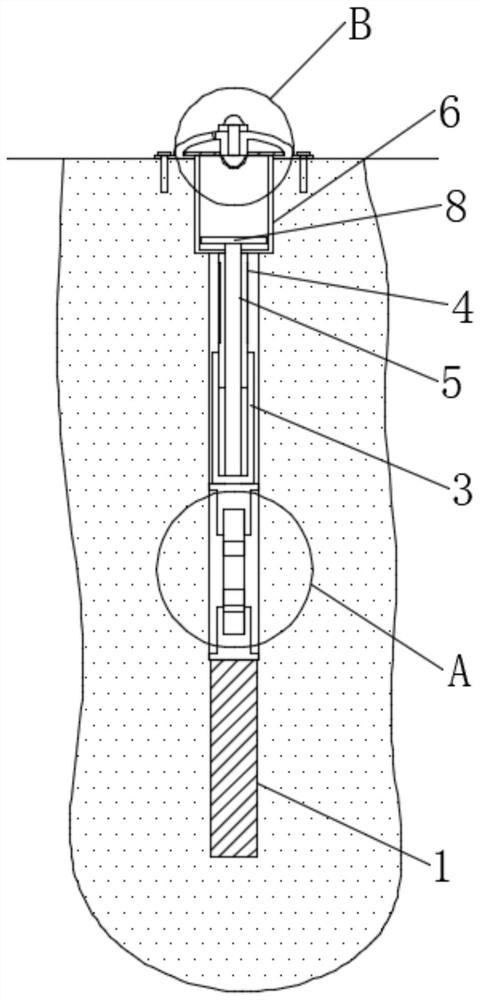

[0042] see Figure 1-3 , a distributed ladder blasting equipment, including a blasting detonator main body 1, the upper end of the blasting detonator main body 1 is fixedly connected with an isolation frame 2, and the isolation frame 2 includes a pair of isolation covers 201, and the outer wall of the isolation cover 201 is fixedly connected with a plurality of uniform The distributed barbs make the isolation cover 201 firmly fixed with the soil. A support ring 202 is connected between a pair of isolation covers 201, and the two points of the support ring 202 are fixedly connected with a protection cylinder 203. The protection cylinder 203 is a high-pressure tank, and the support ring 202 is a steel ring with two ends sharpened. Between the two high-pressure tanks, thermosetting resin is stored in the high-pressure tank. After the explosion, the high-pressure tank is squeezed and unsealed by the steel ring, and the thermosetting resin in the high-pressure tank leaks. At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com