Modularized single-double throat switching type steam generating device

A generation device and double-throat technology, applied in the field of modularized single-dual-throat switchable steam generation device, can solve the problems of steam pressure not meeting the requirements, low ignition reliability, flammability and explosion, etc., to reduce safety risks and test cost, the effect of preventing the extreme danger of cross-cavity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

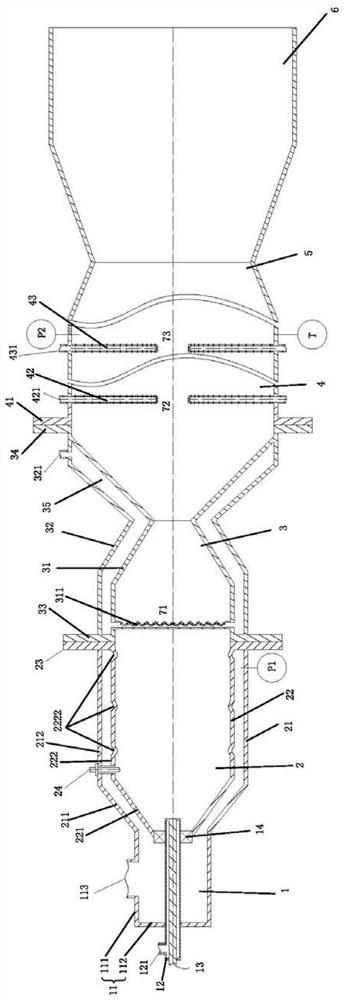

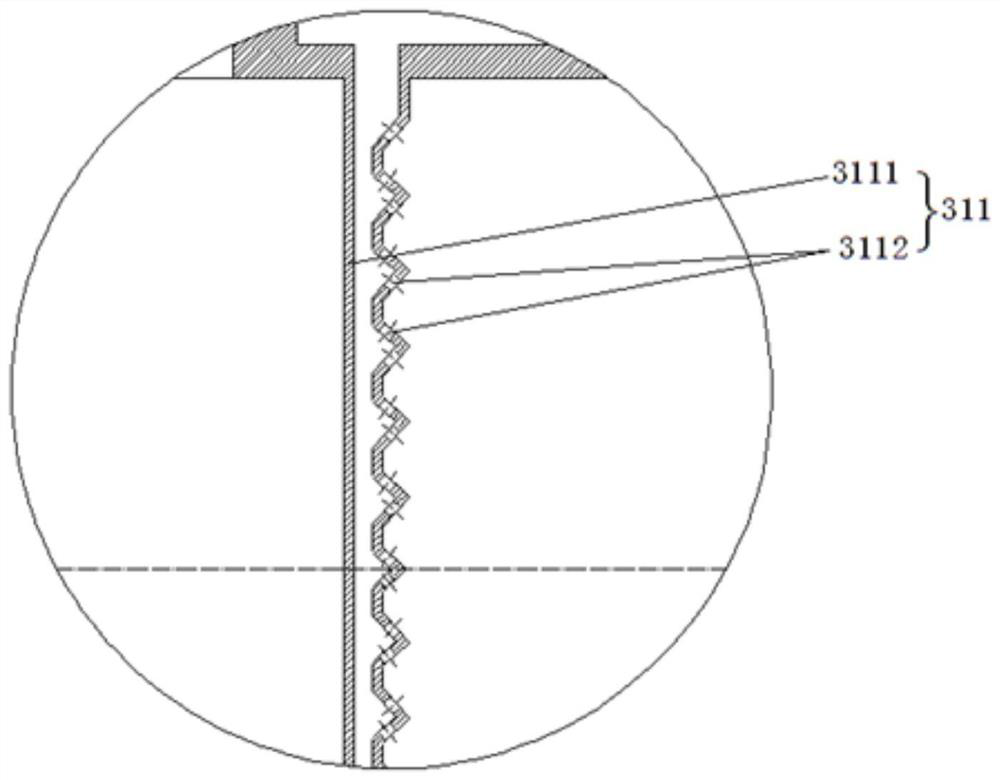

[0051] Such as figure 1 As shown, a modularized single-dual-throat switching steam generating device consists of a head 1, a combustion chamber 2, a first throat 3, a mixing chamber 4, a second throat 5 and an outlet chamber 6 connected coaxially in sequence. composition.

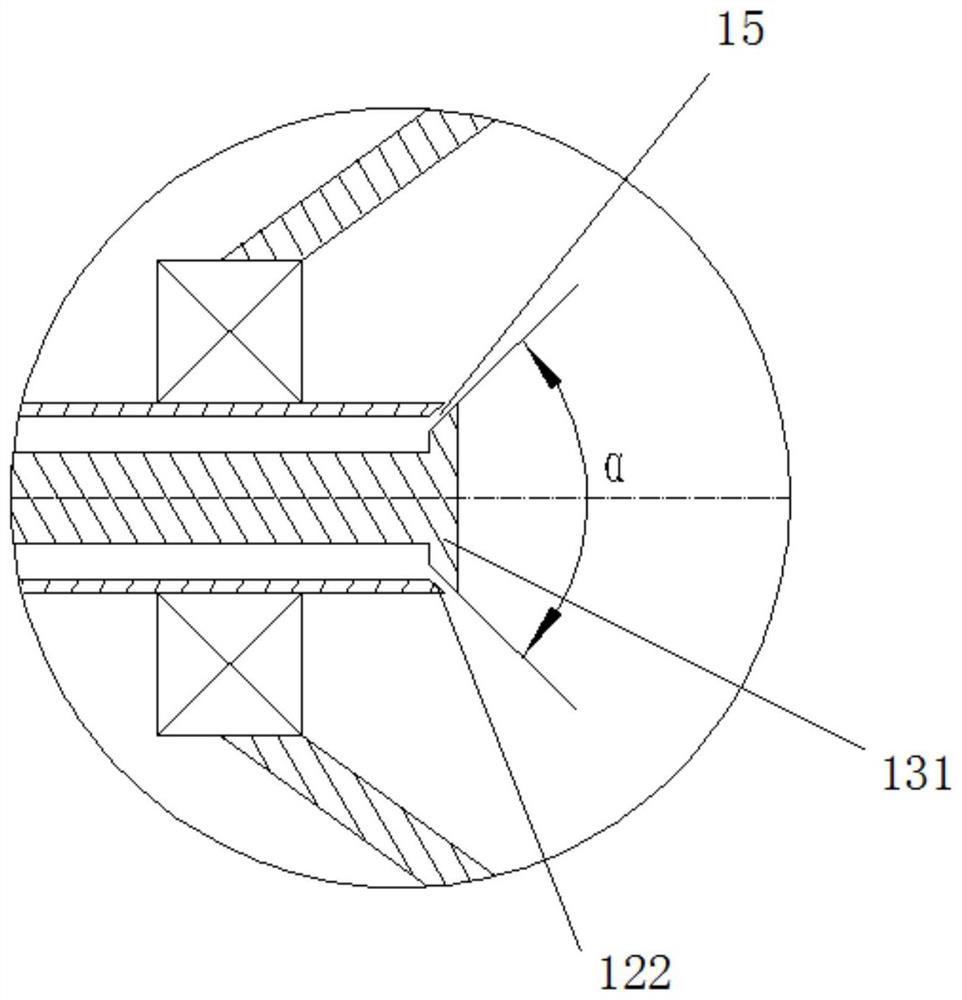

[0052] The head 1 includes a head housing 11, a support pipe 12, an alcohol nozzle center body 13 and a swirler 14. The head housing 11 includes a sleeve 111 and an end cap 112 arranged at the front end of the sleeve 111. The side of the sleeve 111 The wall is provided with an air inlet 113; the support tube 12 is a casing structure, and its front end is arranged on the end cover 112 and the front side wall extending out of the end cover 112 is provided with an alcohol inlet 121, and the rear end extends into the combustion chamber 2 and ends The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com