Method for processing TVS chip after blue film pasting

A processing method, blue film technology, applied in the direction of metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of easily damaged core grain corners, core grains are easy to scatter, and seamless transportation, etc., to improve quality and improve Effects of improving processing efficiency and quality, packaging efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

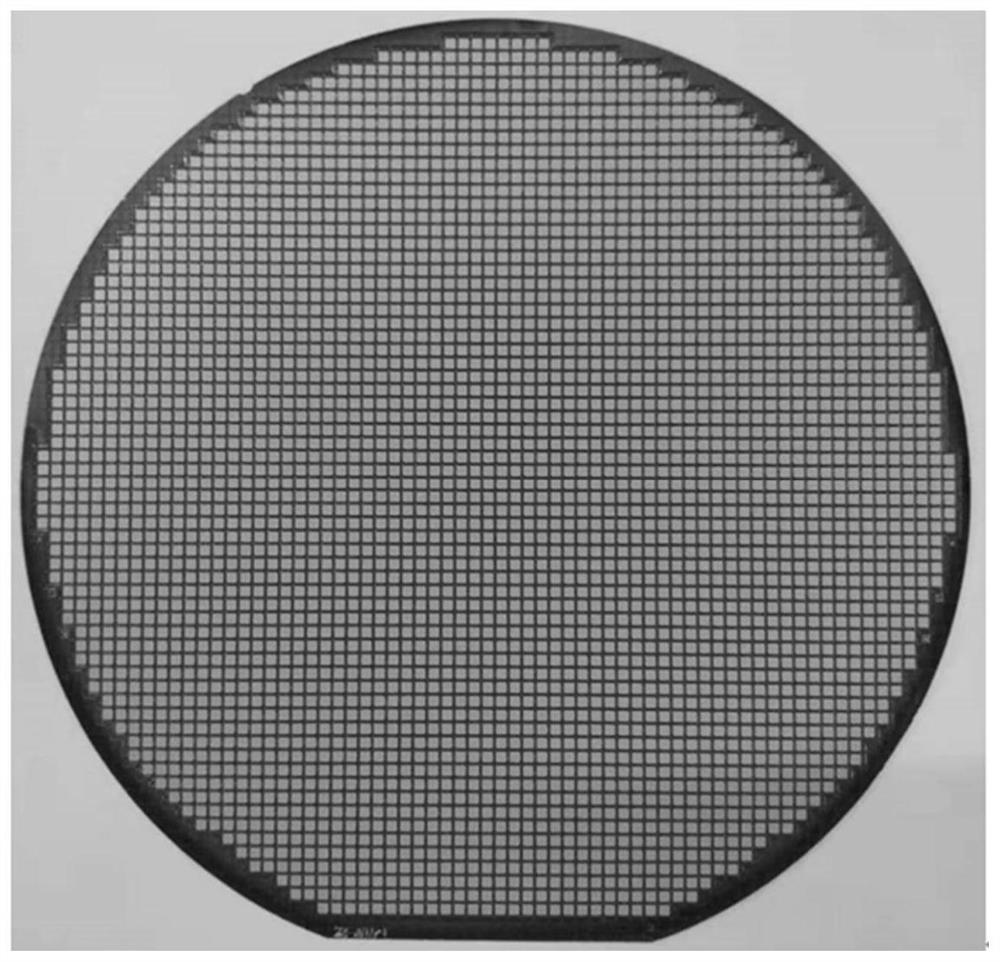

[0037] For step S2 laser half-cutting: Use a laser cutting machine to half-cut the wafer along the scribing lane. The cutting speed of the laser cutting machine is 150mm / s, the cutting frequency is 45KHz, the cutting power is 58%, the cutting depth is 90um, and the cutting mark width 43±5um.

[0038] Variation 2

[0039] For step S2, laser half-cutting includes two cutting steps: the first cutting: the cutting speed of the laser cutting machine is 125mm / s, the cutting frequency is 35KHz, and the cutting power is 66%. The second cutting: the cutting speed of the laser cutting machine is 150mm / s, the cutting frequency is 45KHz, the cutting power is 45%; the cutting depth is 110um, and the cutting mark width is 43±5um.

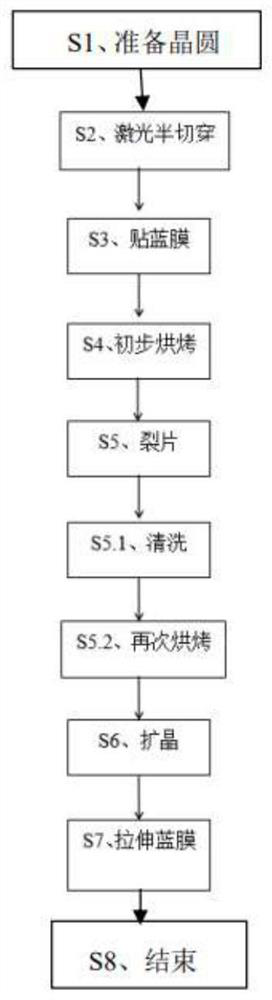

[0040] working principle

[0041] During the work, the wafer preparation step, the laser half-cutting step, the blue film step, the preliminary baking step, the slitting step, the cleaning step, the rebaking step, the crystal expansion step, and the stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com