Generator heat dissipation system of spraying machine

A heat dissipation system and spray system technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increased manufacturing costs, large rectifier bridge heat generation, fan consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

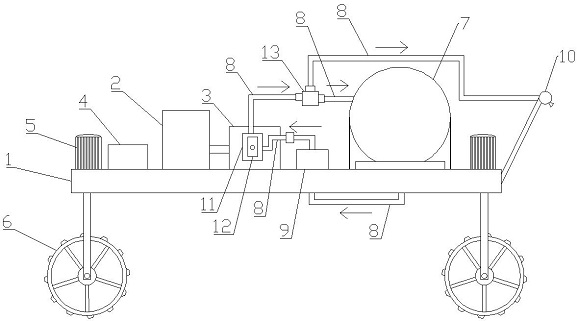

[0016] A generator heat dissipation system of a sprayer of the present embodiment, refer to the attached figure 1 , the direction of the arrow in the figure is the flow direction of the liquid medicine. The generator cooling system of described sprayer comprises car body 1, power unit and spraying system, and power unit and spraying system are arranged on car body 1, and power unit comprises internal combustion engine 2 and the generator 3 that is connected with internal combustion engine 2, and internal combustion engine 2 drives The generator 3 generates electricity and supplies the electrical components of the spray system, which include the main control device 4, the pump 9, etc., such as figure 1 As shown in , the motor 5 is connected to the wheel 6 through the transmission structure, and the motor 5 drives the wheel 6 to drive the spraying system to walk. At this time, the generator 3 also supplies power to the motor 5. At this time, the generator 3 has a large load and ...

Embodiment 2

[0020] The basic structure and principle of this embodiment are the same as those of the first embodiment above, the difference is that the liquid cooling radiator 11 is provided with a temperature measuring device with temperature display, and the temperature measuring device is preferably an electronic device with a display screen. The temperature measuring device is convenient for the operator to observe. The infusion pipe 8 between the pump 9 and the liquid cooling radiator 11 or the infusion pipe 8 between the liquid cooling radiator 11 and the three-way valve is provided with a manual flow regulating valve.

[0021] In this embodiment, during the spraying operation, the operator adjusts the spray flow through the manual flow regulating valve to meet the needs of different operations. When the field transitions, the temperature of the rectifying strip 12 is grasped by observing the temperature measuring device, and the manual flow adjustment is manually adjusted. The valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com